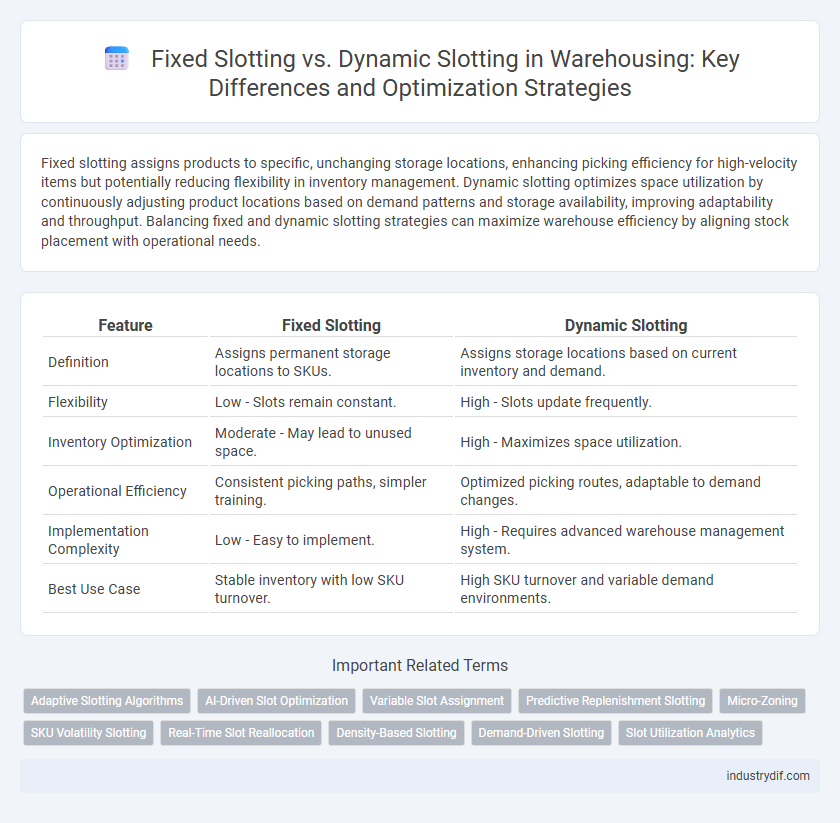

Fixed slotting assigns products to specific, unchanging storage locations, enhancing picking efficiency for high-velocity items but potentially reducing flexibility in inventory management. Dynamic slotting optimizes space utilization by continuously adjusting product locations based on demand patterns and storage availability, improving adaptability and throughput. Balancing fixed and dynamic slotting strategies can maximize warehouse efficiency by aligning stock placement with operational needs.

Table of Comparison

| Feature | Fixed Slotting | Dynamic Slotting |

|---|---|---|

| Definition | Assigns permanent storage locations to SKUs. | Assigns storage locations based on current inventory and demand. |

| Flexibility | Low - Slots remain constant. | High - Slots update frequently. |

| Inventory Optimization | Moderate - May lead to unused space. | High - Maximizes space utilization. |

| Operational Efficiency | Consistent picking paths, simpler training. | Optimized picking routes, adaptable to demand changes. |

| Implementation Complexity | Low - Easy to implement. | High - Requires advanced warehouse management system. |

| Best Use Case | Stable inventory with low SKU turnover. | High SKU turnover and variable demand environments. |

Introduction to Slotting in Warehousing

Slotting in warehousing optimizes product storage by assigning inventory locations based on factors like order frequency and item size. Fixed slotting designates permanent storage spots for specific products, enhancing picking accuracy and reducing training time. Dynamic slotting adjusts storage locations regularly according to demand patterns, improving space utilization and operational efficiency.

What Is Fixed Slotting?

Fixed slotting in warehousing refers to assigning permanent storage locations for specific products based on factors like size, weight, and demand frequency. This method enhances picking efficiency by reducing travel time and minimizing errors, especially in stable inventory environments. Fixed slotting is ideal for warehouses with consistent product assortments and predictable order patterns.

What Is Dynamic Slotting?

Dynamic slotting is a warehouse management strategy that continuously adjusts product storage locations based on real-time data such as demand patterns, order frequency, and inventory levels. This approach enhances space utilization, reduces travel time for pickers, and improves overall operational efficiency compared to fixed slotting, where products remain in assigned, unchanging locations. Leveraging technology like warehouse management systems (WMS), dynamic slotting optimizes slot assignments to boost productivity and responsiveness in fast-paced distribution environments.

Key Differences Between Fixed and Dynamic Slotting

Fixed slotting assigns specific locations to inventory items, promoting consistency and ease of item retrieval, which is ideal for stable product demand and low SKU variability. Dynamic slotting continuously adjusts item locations based on real-time data, optimizing space utilization and improving picking efficiency in environments with high SKU turnover and fluctuating demand. The key difference lies in fixed slotting's static assignments versus dynamic slotting's flexibility to adapt to inventory changes, impacting warehouse layout, labor costs, and overall operational agility.

Benefits of Fixed Slotting

Fixed slotting enhances warehouse efficiency by assigning specific locations for each SKU, reducing search time and minimizing errors during order picking. This system supports consistent inventory management and simplifies employee training due to the predictability of item placement. Furthermore, fixed slotting improves space utilization by optimizing storage layouts based on product size and demand patterns.

Advantages of Dynamic Slotting

Dynamic slotting improves warehouse efficiency by continuously adjusting product locations based on real-time demand and inventory levels, reducing travel time for pickers. It enhances space utilization by reallocating slots to high-velocity items, maximizing storage density and throughput. This method supports better inventory accuracy and adaptability in fluctuating market conditions, contributing to faster order fulfillment and reduced operational costs.

Challenges of Fixed Slotting

Fixed slotting faces significant challenges such as limited flexibility to adapt to fluctuating inventory levels and seasonal demand variations, leading to underutilized space or congestion in storage locations. It can cause inefficiencies in picking paths due to predetermined placements that may not align with real-time order patterns, increasing labor costs and processing time. Moreover, fixed slotting requires extensive initial planning and ongoing manual adjustments, hindering scalability and responsiveness in fast-paced warehouse operations.

Limitations of Dynamic Slotting

Dynamic slotting in warehousing often faces limitations such as increased complexity in inventory management due to frequent slot changes and the need for sophisticated software to track real-time product locations. This approach can lead to higher labor costs as employees require additional training and time to adapt to constantly shifting storage assignments. Additionally, dynamic slotting may cause inefficiencies during peak periods when rapid access to high-demand items is critical, potentially slowing down order fulfillment.

Criteria for Choosing the Right Slotting Method

Selecting the appropriate slotting method hinges on factors such as inventory turnover rates, product variety, and order picking frequency. Fixed slotting suits warehouses with stable demand and consistent SKUs, optimizing efficiency through repetitive placement. Dynamic slotting benefits environments with fluctuating inventory and variable demand, allowing continuous adjustment to maximize space utilization and reduce travel time.

Future Trends in Warehouse Slotting Optimization

Future trends in warehouse slotting optimization emphasize the integration of AI-driven algorithms and real-time data analytics to enhance both fixed and dynamic slotting strategies. Fixed slotting benefits from predictive analytics to assign high-velocity SKUs to optimal locations, while dynamic slotting leverages machine learning for continuous adjustment based on order patterns and seasonal demand. Combining IoT sensors with cloud-based warehouse management systems (WMS) will further enable seamless adaptation, increasing efficiency and reducing picking errors in evolving e-commerce and omnichannel environments.

Related Important Terms

Adaptive Slotting Algorithms

Adaptive slotting algorithms in warehousing optimize storage locations by continuously analyzing order patterns and inventory turnover rates, enabling dynamic adjustments that outperform traditional fixed slotting systems. These algorithms increase picking efficiency and reduce travel time by automatically reallocating products based on real-time data and demand variability.

AI-Driven Slot Optimization

AI-driven slot optimization leverages machine learning algorithms to analyze real-time data and adapt warehouse slotting dynamically, enhancing storage efficiency and reducing picking time. Fixed slotting relies on predetermined locations, limiting flexibility and responsiveness to demand fluctuations compared to AI-powered dynamic slotting systems.

Variable Slot Assignment

Variable slot assignment in warehousing optimizes space utilization by dynamically allocating storage locations based on real-time inventory levels and product demand variability, enhancing picking efficiency and reducing travel time. This approach contrasts with fixed slotting by adapting warehouse layout frequently, promoting flexibility and responsiveness in high-velocity distribution environments.

Predictive Replenishment Slotting

Predictive replenishment slotting enhances dynamic slotting by analyzing historical demand data and forecast trends to allocate inventory efficiently, reducing stockouts and minimizing travel time within the warehouse. Fixed slotting assigns products to designated locations regardless of demand fluctuations, often leading to inefficiencies that predictive replenishment slotting mitigates through continuous slot optimization.

Micro-Zoning

Fixed slotting assigns products to permanent locations, optimizing picking efficiency through consistent micro-zoning by grouping similar items within defined warehouse segments. Dynamic slotting uses real-time data to adjust product placements, enhancing space utilization and reducing travel time within micro-zoned areas by adapting slot assignments based on demand patterns.

SKU Volatility Slotting

Dynamic slotting adapts SKU locations based on real-time demand fluctuations and SKU volatility, optimizing pick efficiency and reducing travel time in warehouses with high SKU turnover. Fixed slotting assigns SKUs to constant locations, offering stability but potentially decreasing efficiency when SKU demand patterns are volatile and unpredictable.

Real-Time Slot Reallocation

Real-time slot reallocation enhances warehouse efficiency by dynamically adjusting inventory locations based on current demand patterns and order frequency; unlike fixed slotting which assigns permanent storage locations, dynamic slotting maximizes space utilization and reduces picking time through continuous data-driven optimization. Implementing warehouse management systems (WMS) with real-time analytics enables seamless slot reallocation, improving overall throughput and operational agility in high-volume distribution centers.

Density-Based Slotting

Density-based slotting optimizes warehouse space by placing high-density, slow-moving items in less accessible areas while positioning low-density, fast-moving products in prime picking zones to enhance efficiency. This approach contrasts with fixed slotting's static assignment and dynamic slotting's continuous reshuffling, providing a balanced strategy that maximizes storage density and picking speed.

Demand-Driven Slotting

Demand-driven slotting in warehousing dynamically allocates inventory locations based on real-time demand patterns, enhancing picking efficiency and reducing travel time. This approach contrasts with fixed slotting by adapting storage positions to fluctuating order volumes and product velocity, optimizing space utilization and operational responsiveness.

Slot Utilization Analytics

Fixed slotting offers consistent storage locations, enabling straightforward tracking and stable slot utilization analytics, while dynamic slotting adjusts storage based on demand patterns, enhancing real-time slot utilization and minimizing wasted space. Advanced slot utilization analytics leverage data from dynamic slotting to optimize inventory flow and maximize warehouse efficiency by identifying underused slots and reallocating space according to item velocity.

Fixed Slotting vs Dynamic Slotting Infographic

industrydif.com

industrydif.com