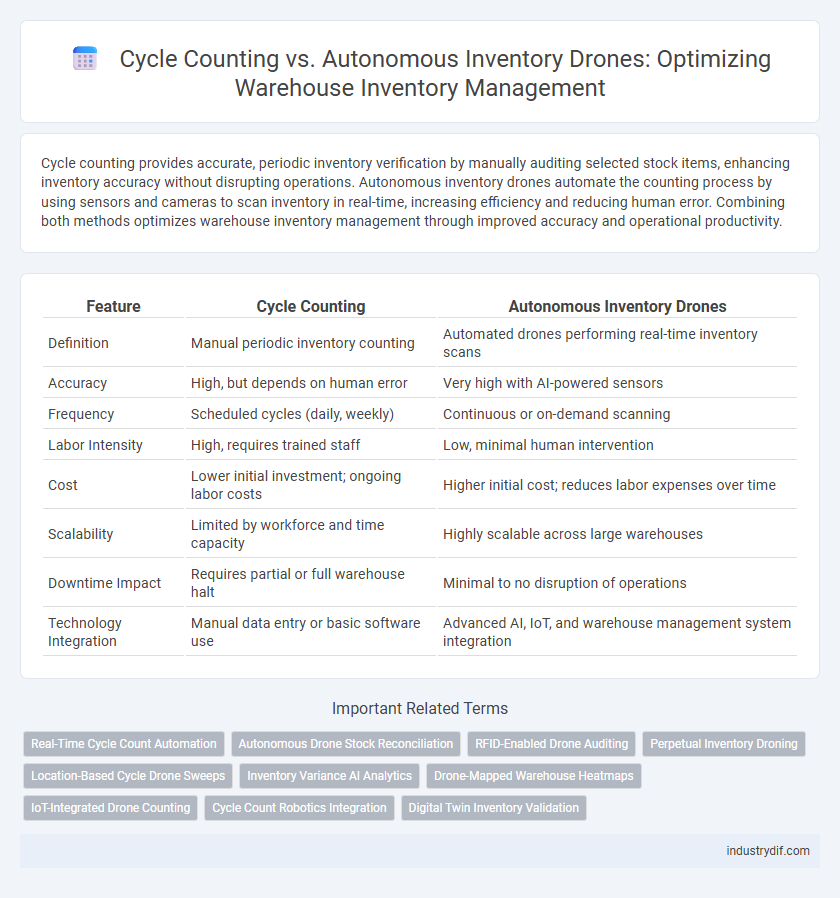

Cycle counting provides accurate, periodic inventory verification by manually auditing selected stock items, enhancing inventory accuracy without disrupting operations. Autonomous inventory drones automate the counting process by using sensors and cameras to scan inventory in real-time, increasing efficiency and reducing human error. Combining both methods optimizes warehouse inventory management through improved accuracy and operational productivity.

Table of Comparison

| Feature | Cycle Counting | Autonomous Inventory Drones |

|---|---|---|

| Definition | Manual periodic inventory counting | Automated drones performing real-time inventory scans |

| Accuracy | High, but depends on human error | Very high with AI-powered sensors |

| Frequency | Scheduled cycles (daily, weekly) | Continuous or on-demand scanning |

| Labor Intensity | High, requires trained staff | Low, minimal human intervention |

| Cost | Lower initial investment; ongoing labor costs | Higher initial cost; reduces labor expenses over time |

| Scalability | Limited by workforce and time capacity | Highly scalable across large warehouses |

| Downtime Impact | Requires partial or full warehouse halt | Minimal to no disruption of operations |

| Technology Integration | Manual data entry or basic software use | Advanced AI, IoT, and warehouse management system integration |

Introduction to Cycle Counting and Autonomous Inventory Drones

Cycle counting is a systematic warehouse inventory auditing method involving the frequent, partial counting of stock to maintain accurate inventory records and minimize disruption to operations. Autonomous inventory drones utilize advanced robotics and AI technology to conduct real-time, precise stock assessments, reducing human error and increasing inventory visibility. Both methods aim to enhance inventory accuracy, but drones offer scalability and automation benefits for large-scale warehousing environments.

Defining Cycle Counting in Modern Warehousing

Cycle counting in modern warehousing is a systematic inventory auditing process where specific portions of stock are counted on a scheduled basis to maintain accuracy without halting operations. This method relies on strategic frequency and targeted locations to identify discrepancies early, ensuring continuous inventory integrity. Cycle counting reduces the need for comprehensive physical inventories, improving operational efficiency and data accuracy in warehouse management systems.

How Autonomous Inventory Drones Work

Autonomous inventory drones utilize advanced sensors and AI-driven navigation systems to conduct real-time warehouse stock assessments, flying through aisles and scanning barcodes or RFID tags with precision. These drones integrate with warehouse management systems to automatically update inventory records, reducing human error and increasing counting frequency compared to traditional cycle counting methods. By continuously monitoring stock levels and location data, autonomous inventory drones enable efficient, accurate, and scalable inventory control in large warehousing operations.

Key Differences Between Cycle Counting and Drones

Cycle counting relies on manual physical inventory checks conducted by warehouse staff at scheduled intervals to ensure accuracy, while autonomous inventory drones utilize automated flight and scanning technology for continuous, real-time stock monitoring. Cycle counting is labor-intensive and prone to human error, whereas drones offer higher precision and efficiency by quickly capturing inventory data using sensors and AI-driven image recognition. The primary difference lies in cycle counting's periodic data collection versus drones' capability for constant, non-disruptive inventory updates within expansive warehouse environments.

Accuracy and Efficiency Comparisons

Cycle counting maintains high inventory accuracy through targeted, manual stock verification but often requires significant labor and time. Autonomous inventory drones leverage advanced sensors and AI to rapidly scan entire warehouses, increasing efficiency while reducing human error. Combining drone technology with cycle counting protocols can enhance real-time accuracy and operational productivity in warehousing.

Labor and Operational Cost Implications

Cycle counting reduces labor costs by enabling targeted inventory checks without halting warehouse operations, while autonomous inventory drones further lower operational expenses through automated, continuous stock monitoring with minimal human intervention. Drones provide enhanced accuracy and speed, decreasing errors and labor hours compared to manual cycle counts reliant on workforce availability and training. Investment in autonomous drones results in long-term savings despite initial capital expenditure, optimizing workforce allocation and supporting scalable warehouse operations.

Integration with Warehouse Management Systems

Cycle counting enhances inventory accuracy through periodic manual checks but relies heavily on integration with Warehouse Management Systems (WMS) for real-time data updates and error tracking. Autonomous inventory drones offer seamless integration with WMS by providing continuous, automated stock monitoring using RFID and barcode scanning technologies, significantly reducing human error. The advanced data synchronization between drones and WMS supports proactive inventory management, optimizing stock levels and operational efficiency.

Safety and Compliance Considerations

Cycle counting improves accuracy and reduces inventory discrepancies by enabling frequent manual checks, but it requires strict adherence to safety protocols to prevent accidents in high-traffic warehouse environments. Autonomous inventory drones enhance safety by minimizing human involvement in hazardous areas and complying with regulatory standards through automated data capture and real-time monitoring. Both methods must align with OSHA guidelines and industry compliance requirements to ensure a secure and efficient inventory management process.

Scalability for Large-Scale Warehousing Operations

Cycle counting enhances inventory accuracy through regular manual audits but faces limitations in scalability for large-scale warehousing operations due to labor intensity and time constraints. Autonomous inventory drones leverage advanced AI and real-time data processing to conduct rapid, continuous stock assessments, significantly reducing downtime and labor costs. Integration of drone technology offers scalable solutions for vast warehouses by enabling comprehensive coverage with minimal human intervention and enhanced data accuracy.

Future Trends in Inventory Management Technology

Cycle counting remains a foundational inventory accuracy method, but future trends highlight the rise of autonomous inventory drones equipped with AI for real-time stock monitoring and faster error detection. These drones optimize warehouse operations by minimizing human labor, reducing cycle count times by up to 70%, and improving data precision through automated scanning. Integration of autonomous drones with warehouse management systems (WMS) and IoT sensors represents a key advancement driving predictive analytics and enhanced inventory control.

Related Important Terms

Real-Time Cycle Count Automation

Real-time cycle count automation enhances inventory accuracy by integrating autonomous inventory drones equipped with advanced sensors and AI, enabling continuous, precise stock level monitoring without disrupting warehouse operations. This technology surpasses traditional manual cycle counting by reducing human error, expediting inventory audits, and providing instant data updates to warehouse management systems.

Autonomous Drone Stock Reconciliation

Autonomous inventory drones streamline cycle counting by performing real-time stock reconciliation with advanced barcode and RFID scanning, significantly reducing human error and labor costs. These drones enhance warehouse efficiency through rapid data collection and automated inventory updates, improving stock accuracy and operational productivity.

RFID-Enabled Drone Auditing

RFID-enabled drone auditing revolutionizes cycle counting by automating inventory checks, significantly reducing human error and labor costs while enhancing real-time data accuracy. This innovative technology integrates RFID scanning with autonomous drones, enabling precise and efficient warehouse inventory management compared to traditional manual cycle counting methods.

Perpetual Inventory Droning

Perpetual inventory droning enables continuous, real-time stock monitoring by using autonomous drones equipped with advanced sensors and RFID technology, significantly reducing human error and labor costs compared to traditional cycle counting methods. These drones enhance inventory accuracy and operational efficiency by performing frequent, automated scans without disrupting warehouse workflows.

Location-Based Cycle Drone Sweeps

Location-based cycle drone sweeps in warehousing leverage autonomous drones equipped with RFID and computer vision to perform precise, real-time inventory counts at specific storage locations, significantly reducing human error and labor costs. These drones enhance inventory accuracy by continuously monitoring stock levels and detecting discrepancies faster than traditional cycle counting methods, optimizing stock management and operational efficiency.

Inventory Variance AI Analytics

Cycle counting provides periodic inventory checks that identify discrepancies by comparing physical stock to recorded data, while autonomous inventory drones utilize AI-driven analytics to perform continuous, real-time variance detection with high accuracy. AI-powered inventory variance analytics enable drones to quickly pinpoint stock inaccuracies, reduce human error, and optimize warehouse operations through enhanced data insights and timely adjustments.

Drone-Mapped Warehouse Heatmaps

Cycle counting enhances inventory accuracy through periodic manual stock audits, while autonomous inventory drones leverage advanced sensors and AI to perform real-time data collection. Drone-mapped warehouse heatmaps visualize storage efficiency and identify high-traffic zones, enabling precise inventory management and optimizing warehouse layout.

IoT-Integrated Drone Counting

IoT-integrated autonomous inventory drones enhance cycle counting accuracy by providing real-time data synchronization with warehouse management systems, reducing human error and operational downtime. These drones utilize advanced sensors and AI algorithms to perform rapid, precise stock audits, increasing inventory transparency and boosting overall supply chain efficiency.

Cycle Count Robotics Integration

Cycle counting improves inventory accuracy by regularly auditing stock levels, while integrating autonomous inventory drones enhances this process with real-time data collection and reduced labor costs. Robotics integration combines cycle count methodologies with drone technology to optimize warehouse efficiency, minimize errors, and enable continuous inventory monitoring without disrupting operations.

Digital Twin Inventory Validation

Cycle counting enhances inventory accuracy through periodic manual audits, while autonomous inventory drones leverage real-time data capture paired with digital twin technology for continuous, dynamic inventory validation. Integrating digital twins with drone-based systems enables precise synchronization of physical stock and virtual inventory models, reducing discrepancies and optimizing warehouse management efficiency.

Cycle Counting vs Autonomous Inventory Drones Infographic

industrydif.com

industrydif.com