Cold storage facilities provide consistent low temperatures ideal for storing perishable goods like food and pharmaceuticals, ensuring product safety and extending shelf life. Temperature-controlled smart pods offer precise, customizable climate regulation with real-time monitoring, enhancing inventory management and reducing energy consumption. Integrating smart pods within cold storage systems optimizes space utilization and maintains optimal conditions for sensitive products.

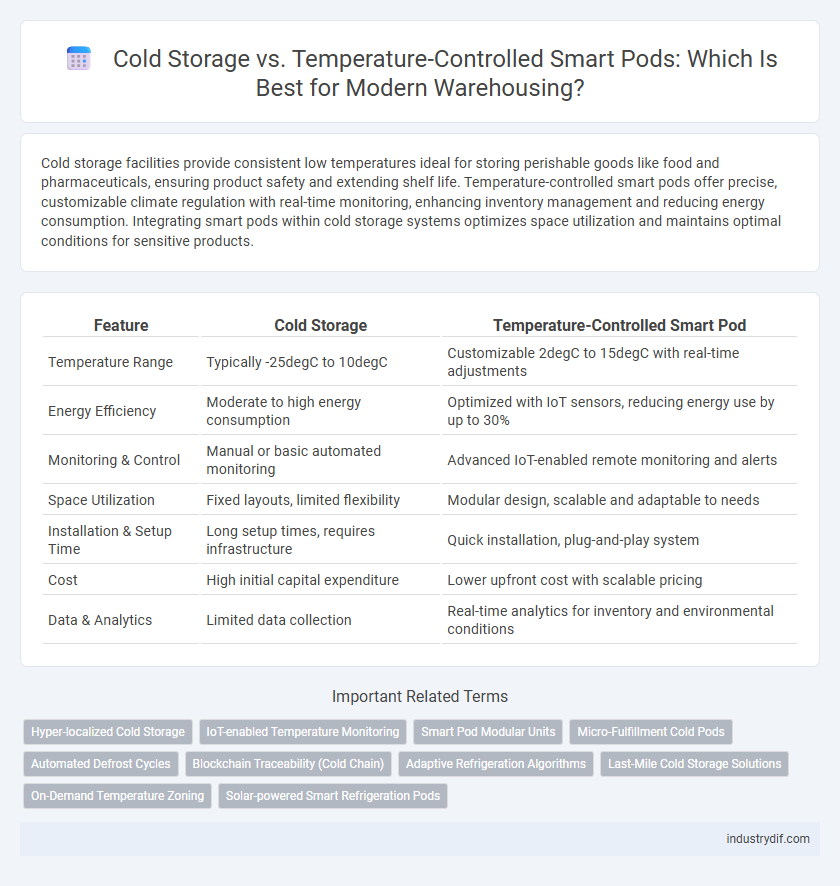

Table of Comparison

| Feature | Cold Storage | Temperature-Controlled Smart Pod |

|---|---|---|

| Temperature Range | Typically -25degC to 10degC | Customizable 2degC to 15degC with real-time adjustments |

| Energy Efficiency | Moderate to high energy consumption | Optimized with IoT sensors, reducing energy use by up to 30% |

| Monitoring & Control | Manual or basic automated monitoring | Advanced IoT-enabled remote monitoring and alerts |

| Space Utilization | Fixed layouts, limited flexibility | Modular design, scalable and adaptable to needs |

| Installation & Setup Time | Long setup times, requires infrastructure | Quick installation, plug-and-play system |

| Cost | High initial capital expenditure | Lower upfront cost with scalable pricing |

| Data & Analytics | Limited data collection | Real-time analytics for inventory and environmental conditions |

Introduction to Cold Storage and Smart Pods

Cold storage facilities maintain subzero temperatures to preserve perishable goods such as food, pharmaceuticals, and chemicals, ensuring extended shelf life and compliance with safety standards. Temperature-controlled smart pods utilize advanced IoT sensors and automation technology to regulate and monitor micro-environmental conditions with high precision, optimizing energy consumption and inventory management. These innovations enhance supply chain efficiency by offering scalable, flexible, and data-driven solutions compared to traditional cold storage methods.

Key Differences Between Cold Storage and Smart Pods

Cold storage facilities maintain consistent low temperatures for bulk perishable goods, emphasizing large-scale refrigeration and energy efficiency over extended periods. Temperature-controlled smart pods use advanced IoT sensors and AI to monitor and adjust conditions dynamically, ensuring precise microclimate control for high-value or sensitive items. Smart pods offer enhanced traceability, remote management, and modular scalability compared to traditional cold storage units.

Technology in Temperature-Controlled Smart Pods

Temperature-controlled smart pods utilize IoT sensors and AI-driven climate control systems to maintain precise temperature and humidity levels, ensuring optimal storage conditions for perishable goods. These advanced technologies enable real-time monitoring and automated adjustments, reducing energy consumption and minimizing spoilage risks compared to traditional cold storage facilities. Integration with cloud platforms allows for remote management and predictive maintenance, enhancing operational efficiency and product safety.

Energy Efficiency and Sustainability

Cold storage facilities traditionally rely on large refrigeration units with high energy consumption, while temperature-controlled smart pods utilize advanced insulation and AI-driven climate regulation to significantly reduce power usage. Smart pods leverage sensors and adaptive algorithms to maintain optimal conditions only where and when needed, minimizing energy waste and enhancing sustainability. This technology supports lower carbon footprints by integrating renewable energy sources and demand-responsive operation in warehousing environments.

Scalability and Flexibility in Warehousing

Cold storage facilities provide reliable temperature regulation for large-scale warehousing but often lack the scalability and flexible reconfiguration needed for fluctuating inventory demands. Temperature-controlled smart pods integrate IoT sensors and modular designs, enabling quick adjustments in capacity and temperature settings tailored to specific product requirements. This adaptability enhances operational efficiency and supports dynamic supply chain workflows in modern warehousing environments.

Cost Comparison: Installation and Operations

Cold storage facilities typically demand higher installation costs due to extensive insulation, refrigeration units, and structural reinforcements. Temperature-controlled smart pods offer a more cost-effective solution with modular designs that reduce upfront expenses and optimize energy consumption through advanced monitoring systems. Operational costs for smart pods remain lower as real-time data adjustments minimize energy waste and maintenance needs compared to traditional cold storage.

Applications: Suitable Industries and Use Cases

Cold storage facilities are essential for preserving perishable goods in industries such as food and pharmaceuticals, maintaining consistent temperatures for produce, dairy, and vaccines. Temperature-controlled smart pods offer advanced monitoring and flexibility, making them ideal for e-commerce, biotech, and specialty food sectors requiring real-time data and adaptive climate regulation. Both solutions optimize supply chains by ensuring product quality, with smart pods providing scalable, remote-controlled environments for sensitive goods.

Security and Monitoring Capabilities

Cold storage facilities employ robust physical security measures and basic temperature alarms, but often lack real-time, remote monitoring and advanced threat detection features. Temperature-controlled smart pods integrate IoT sensors and AI-driven analytics to offer continuous security surveillance, precise environmental monitoring, and instant alerts for unauthorized access or parameter deviations. These smart pods enhance asset protection by combining controlled temperature maintenance with proactive security and monitoring technologies.

Maintenance and Operational Challenges

Cold storage facilities demand rigorous maintenance of refrigeration systems and insulation to prevent temperature fluctuations, often requiring frequent checks and specialized equipment repairs. Temperature-controlled smart pods use advanced IoT sensors and automated climate control, reducing manual intervention but posing challenges in software updates and cybersecurity management. Both systems face operational difficulties in energy consumption and downtime, yet smart pods offer predictive maintenance capabilities that can optimize long-term efficiency.

Future Trends in Temperature-Controlled Warehousing

Future trends in temperature-controlled warehousing highlight the growing adoption of smart pods equipped with IoT sensors and AI-driven climate regulation, enabling real-time monitoring and precise temperature control for perishable goods. Cold storage facilities are evolving to integrate automation and energy-efficient refrigeration systems, reducing operational costs and minimizing food spoilage. Advances in data analytics and predictive maintenance further enhance the reliability and sustainability of temperature-controlled environments in warehousing.

Related Important Terms

Hyper-localized Cold Storage

Hyper-localized cold storage facilities offer precise temperature control tailored to immediate regional demands, reducing transit times and preserving product freshness more effectively than traditional temperature-controlled smart pods. These compact, strategically placed warehouses enhance supply chain efficiency by minimizing spoilage and energy consumption through localized inventory management.

IoT-enabled Temperature Monitoring

Cold storage facilities maintain consistent low temperatures using traditional refrigeration systems, while temperature-controlled smart pods employ IoT-enabled sensors for real-time temperature monitoring and precise climate control. These smart pods enhance inventory safety by providing continuous data analytics and automated alerts, reducing spoilage and operational costs in warehousing environments.

Smart Pod Modular Units

Smart Pod modular units offer advanced temperature control with precise monitoring, energy efficiency, and scalability compared to traditional cold storage facilities. These units integrate IoT sensors and automation to optimize inventory freshness and reduce operational costs in warehousing environments.

Micro-Fulfillment Cold Pods

Micro-fulfillment cold pods leverage temperature-controlled smart pod technology to optimize cold storage efficiency by providing precise climate regulation and rapid product access within compact warehouse environments. This innovation surpasses traditional cold storage by minimizing energy consumption, reducing spoilage, and enabling seamless integration with automated inventory management systems.

Automated Defrost Cycles

Automated defrost cycles in cold storage units minimize ice buildup, ensuring consistent temperature control and reducing energy consumption. Temperature-controlled smart pods enhance this process with sensors and IoT integration, enabling precise monitoring and adaptive defrost scheduling to maximize efficiency and product preservation.

Blockchain Traceability (Cold Chain)

Cold storage facilities integrated with blockchain traceability systems ensure real-time tracking and immutable recording of temperature data, minimizing spoilage and enhancing compliance in cold chain logistics. Temperature-controlled smart pods leverage blockchain technology to provide decentralized, transparent monitoring, enabling precise environmental control and seamless verification throughout the warehousing process.

Adaptive Refrigeration Algorithms

Adaptive refrigeration algorithms in temperature-controlled smart pods dynamically adjust cooling levels based on real-time sensor data, optimizing energy consumption and preserving product quality more efficiently than traditional cold storage. These intelligent systems reduce operational costs and enhance inventory freshness by precisely managing temperature fluctuations within micro-environments.

Last-Mile Cold Storage Solutions

Cold storage warehouses provide traditional temperature-controlled environments essential for preserving perishables during long-term storage, but temperature-controlled smart pods offer advanced last-mile cold storage solutions with dynamic temperature regulation and IoT monitoring for real-time inventory management. These smart pods enhance flexibility, reduce spoilage, and improve delivery efficiency by maintaining precise conditions closer to the customer endpoint.

On-Demand Temperature Zoning

Cold storage facilities maintain fixed temperature zones ideal for bulk, uniform goods but lack flexibility for dynamic inventory needs. In contrast, temperature-controlled smart pods offer on-demand temperature zoning, enabling precise microclimate control for diverse products within a single warehouse space.

Solar-powered Smart Refrigeration Pods

Solar-powered smart refrigeration pods offer a sustainable alternative to traditional cold storage by integrating advanced temperature control technology with renewable energy, reducing operational costs and carbon footprint. These temperature-controlled smart pods utilize IoT sensors to optimize cooling efficiency, ensuring consistent preservation of perishable goods while leveraging solar energy for continuous, eco-friendly power supply.

Cold Storage vs Temperature-controlled Smart Pod Infographic

industrydif.com

industrydif.com