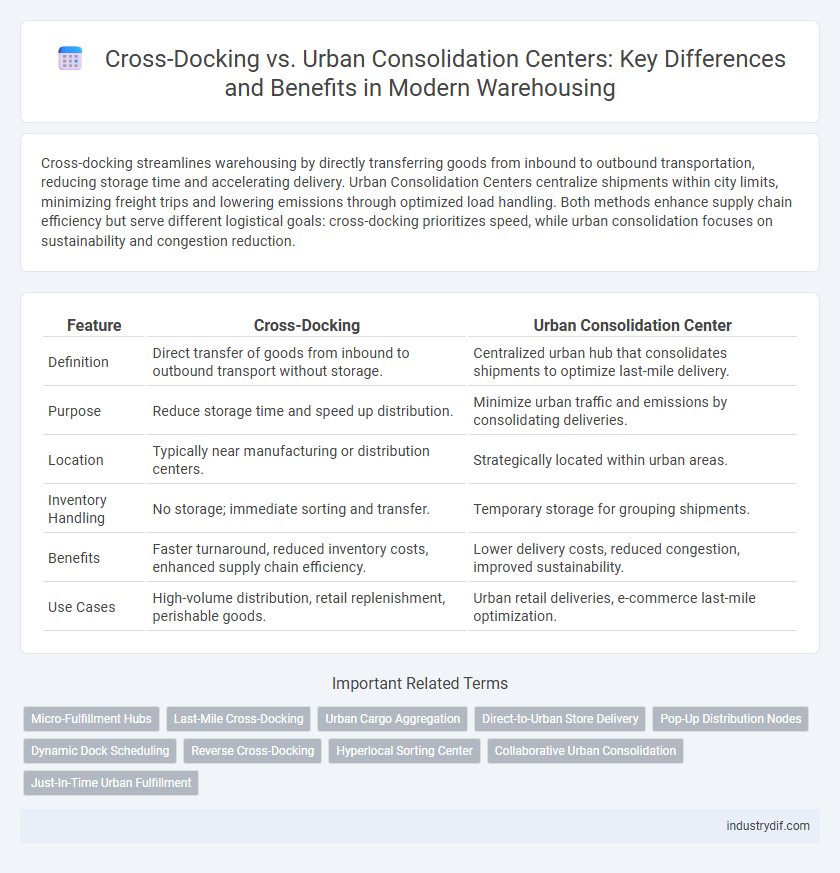

Cross-docking streamlines warehousing by directly transferring goods from inbound to outbound transportation, reducing storage time and accelerating delivery. Urban Consolidation Centers centralize shipments within city limits, minimizing freight trips and lowering emissions through optimized load handling. Both methods enhance supply chain efficiency but serve different logistical goals: cross-docking prioritizes speed, while urban consolidation focuses on sustainability and congestion reduction.

Table of Comparison

| Feature | Cross-Docking | Urban Consolidation Center |

|---|---|---|

| Definition | Direct transfer of goods from inbound to outbound transport without storage. | Centralized urban hub that consolidates shipments to optimize last-mile delivery. |

| Purpose | Reduce storage time and speed up distribution. | Minimize urban traffic and emissions by consolidating deliveries. |

| Location | Typically near manufacturing or distribution centers. | Strategically located within urban areas. |

| Inventory Handling | No storage; immediate sorting and transfer. | Temporary storage for grouping shipments. |

| Benefits | Faster turnaround, reduced inventory costs, enhanced supply chain efficiency. | Lower delivery costs, reduced congestion, improved sustainability. |

| Use Cases | High-volume distribution, retail replenishment, perishable goods. | Urban retail deliveries, e-commerce last-mile optimization. |

Definition of Cross-Docking

Cross-docking is a logistics practice where incoming goods are directly transferred from inbound to outbound transportation with minimal or no storage time, enhancing supply chain efficiency. This method reduces inventory holding costs and accelerates order fulfillment by eliminating the need for warehousing. Unlike Urban Consolidation Centers, which aggregate goods to optimize last-mile delivery in urban areas, cross-docking focuses on streamlining the flow of goods through distribution centers to improve turnaround times.

Overview of Urban Consolidation Centers

Urban Consolidation Centers (UCCs) streamline last-mile delivery by consolidating goods from multiple suppliers at a central facility, reducing urban traffic congestion and emissions. These centers optimize freight distribution in dense city areas by enabling larger, eco-friendly vehicles to transport consolidated shipments, improving delivery efficiency. UCCs are integral to sustainable urban logistics strategies, enhancing supply chain coordination and minimizing environmental impact.

Key Differences Between Cross-Docking and Urban Consolidation

Cross-docking involves the direct transfer of goods from inbound to outbound transportation with minimal storage, optimizing speed and reducing handling costs in warehouse operations. Urban consolidation centers focus on aggregating shipments from multiple suppliers to streamline last-mile delivery, reducing urban congestion and enhancing delivery efficiency. The primary difference lies in cross-docking's emphasis on fast throughput within warehouses, while urban consolidation centers prioritize logistical optimization for sustainable urban freight distribution.

Operational Workflow Comparison

Cross-docking streamlines inventory handling by transferring goods directly from inbound to outbound transportation with minimal storage, reducing handling time and costs. Urban Consolidation Centers (UCCs) aggregate shipments from multiple suppliers to optimize last-mile delivery, emphasizing inventory consolidation and efficient distribution within urban areas. The operational workflow in cross-docking centers prioritizes speed and real-time coordination, whereas UCCs focus on load optimization, route planning, and reducing urban congestion through consolidated shipments.

Advantages of Cross-Docking

Cross-docking reduces inventory holding costs by minimizing storage time, speeding up order fulfillment and enhancing supply chain efficiency. It lowers transportation expenses through direct transfer of goods from inbound to outbound vehicles, improving delivery speed and reducing lead times. This streamlined process supports just-in-time inventory practices, increasing overall operational agility and responsiveness in warehousing.

Benefits of Urban Consolidation Centers

Urban Consolidation Centers (UCCs) significantly reduce urban freight traffic and emissions by consolidating deliveries into fewer, larger shipments, enhancing sustainability in warehousing logistics. They optimize last-mile delivery efficiency by minimizing multiple small vehicle trips, leading to cost savings and reduced congestion in dense city areas. UCCs also improve delivery reliability and urban air quality, supporting eco-friendly supply chain operations within metropolitan environments.

Challenges in Implementation

Cross-docking faces challenges in synchronization of inbound and outbound shipments, requiring precise timing and real-time data integration to avoid delays and inventory pile-ups. Urban consolidation centers encounter difficulties related to urban logistics constraints, such as congestion management, limited space availability, and compliance with local regulations. Both systems demand advanced technology adoption and stakeholder coordination to optimize operational efficiency and reduce environmental impact in warehousing logistics.

Impact on Last-Mile Delivery

Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transport, significantly reducing last-mile delivery lead times and improving inventory flow. Urban Consolidation Centers (UCCs) aggregate shipments from multiple suppliers, optimizing route planning and decreasing urban congestion, which enhances last-mile delivery efficiency and reduces environmental impact. Both strategies streamline last-mile logistics but differ in operational approach: cross-docking accelerates throughput, while UCCs focus on sustainable delivery consolidation.

Sustainability and Environmental Considerations

Cross-docking minimizes inventory holding, reducing warehouse space and energy consumption, which supports sustainability by lowering carbon footprints in supply chains. Urban Consolidation Centers optimize last-mile delivery by consolidating shipments, decreasing the number of delivery vehicles entering city centers and cutting emissions. Both strategies contribute to environmental efficiency, with cross-docking enhancing operational speed and urban consolidation reducing urban traffic congestion and pollution.

Choosing the Right Solution for Your Supply Chain

Cross-docking minimizes storage time by directly transferring products from inbound to outbound transportation, enhancing efficiency in high-turnover supply chains. Urban Consolidation Centers reduce last-mile delivery costs and emissions by consolidating shipments before final distribution, ideal for dense urban areas with strict environmental regulations. Choosing between these solutions depends on factors like product velocity, delivery frequency, and urban logistics constraints to optimize overall supply chain performance.

Related Important Terms

Micro-Fulfillment Hubs

Cross-docking streamlines inventory flow by transferring products directly from inbound to outbound trucks, minimizing storage time, while urban consolidation centers aggregate shipments to reduce congestion and emissions in city logistics. Micro-fulfillment hubs integrate both strategies by utilizing compact, automated facilities close to consumers for rapid order processing, enhancing last-mile delivery efficiency in dense urban areas.

Last-Mile Cross-Docking

Last-Mile Cross-Docking streamlines urban logistics by directly transferring goods from inbound to outbound vehicles, reducing storage time and enabling faster delivery to end consumers compared to traditional Urban Consolidation Centers. This approach minimizes handling costs, decreases delivery lead times, and optimizes route efficiency in dense city environments.

Urban Cargo Aggregation

Urban Cargo Aggregation in Urban Consolidation Centers (UCCs) optimizes last-mile delivery by combining shipments from multiple suppliers into consolidated loads, reducing traffic congestion and emissions in city centers. Cross-docking, by contrast, primarily focuses on rapid transfer of goods through distribution hubs without storage, emphasizing speed over urban environmental benefits.

Direct-to-Urban Store Delivery

Cross-docking streamlines inventory flow by transferring goods directly from inbound to outbound transport, significantly reducing storage time and accelerating direct-to-urban store delivery. Urban Consolidation Centers optimize last-mile logistics by aggregating shipments from multiple suppliers, reducing delivery frequency, traffic congestion, and emissions while enhancing inventory accuracy for urban retailers.

Pop-Up Distribution Nodes

Cross-docking minimizes storage by immediately transferring goods from inbound to outbound transport, enhancing speed and reducing inventory costs. Urban Consolidation Centers leverage pop-up distribution nodes to centralize deliveries, cutting urban congestion and optimizing last-mile logistics efficiency.

Dynamic Dock Scheduling

Dynamic dock scheduling in cross-docking optimizes real-time loading and unloading by synchronizing inbound and outbound shipments, reducing wait times and enhancing throughput. Urban Consolidation Centers leverage dynamic scheduling to coordinate diverse deliveries within city logistics, minimizing congestion and improving last-mile efficiency through timely dock allocations.

Reverse Cross-Docking

Reverse Cross-Docking in warehousing accelerates the return process by directly transferring inbound returns from customers or retailers to outbound transportation without storage, reducing handling time and costs. Urban Consolidation Centers optimize last-mile deliveries by aggregating shipments in centralized urban hubs, but Reverse Cross-Docking specifically enhances efficiency in reverse logistics by minimizing storage needs and enabling faster returns management.

Hyperlocal Sorting Center

Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation, enhancing efficiency in supply chain flow. Hyperlocal sorting centers within urban consolidation centers specialize in rapid sorting and last-mile delivery optimization, reducing delivery times and urban congestion in dense city environments.

Collaborative Urban Consolidation

Collaborative urban consolidation centers (UCCs) streamline last-mile logistics by pooling shipments from multiple retailers to reduce congestion and emissions in urban areas. Cross-docking enables rapid transfer of goods between incoming and outgoing trucks without storage, but integrating it within collaborative UCCs enhances efficiency by optimizing route planning and load consolidation for sustainable urban freight distribution.

Just-In-Time Urban Fulfillment

Cross-docking streamlines inventory flow by minimizing storage time in warehouses, enhancing Just-In-Time urban fulfillment through rapid transfer from inbound to outbound shipments. Urban Consolidation Centers aggregate deliveries, reducing last-mile trips and supporting Just-In-Time fulfillment by synchronizing urban demand with precise delivery schedules.

Cross-Docking vs Urban Consolidation Center Infographic

industrydif.com

industrydif.com