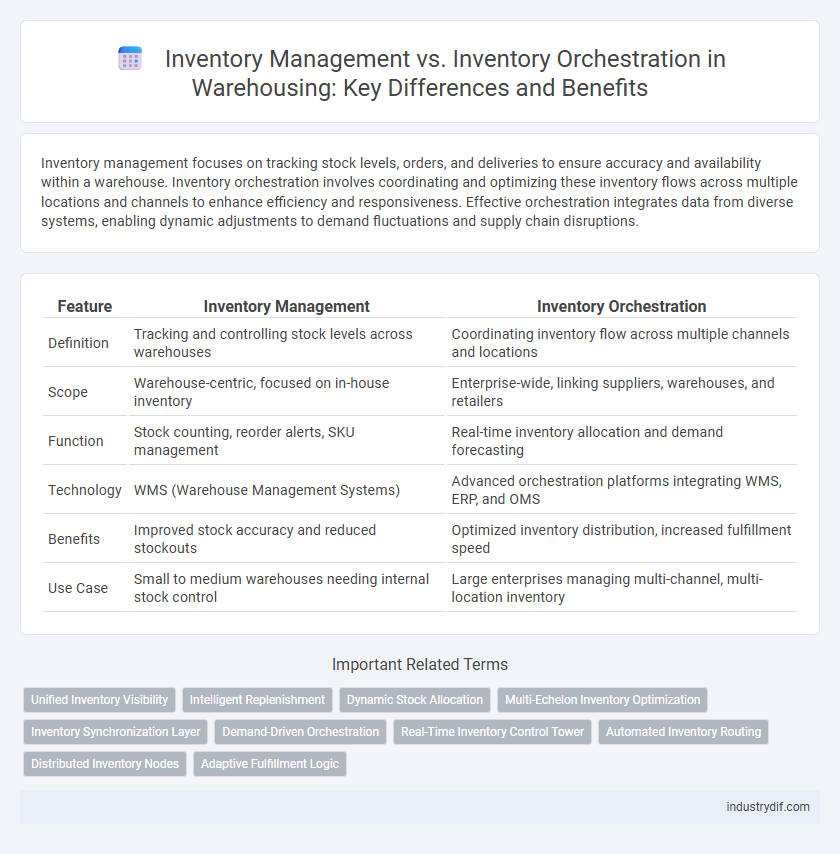

Inventory management focuses on tracking stock levels, orders, and deliveries to ensure accuracy and availability within a warehouse. Inventory orchestration involves coordinating and optimizing these inventory flows across multiple locations and channels to enhance efficiency and responsiveness. Effective orchestration integrates data from diverse systems, enabling dynamic adjustments to demand fluctuations and supply chain disruptions.

Table of Comparison

| Feature | Inventory Management | Inventory Orchestration |

|---|---|---|

| Definition | Tracking and controlling stock levels across warehouses | Coordinating inventory flow across multiple channels and locations |

| Scope | Warehouse-centric, focused on in-house inventory | Enterprise-wide, linking suppliers, warehouses, and retailers |

| Function | Stock counting, reorder alerts, SKU management | Real-time inventory allocation and demand forecasting |

| Technology | WMS (Warehouse Management Systems) | Advanced orchestration platforms integrating WMS, ERP, and OMS |

| Benefits | Improved stock accuracy and reduced stockouts | Optimized inventory distribution, increased fulfillment speed |

| Use Case | Small to medium warehouses needing internal stock control | Large enterprises managing multi-channel, multi-location inventory |

Defining Inventory Management in Warehousing

Inventory management in warehousing involves tracking and controlling stock levels, locations, and movements to ensure efficient order fulfillment and minimize carrying costs. It encompasses processes like demand forecasting, stock replenishment, and cycle counting to maintain accurate inventory records. Effective inventory management reduces stockouts and overstock situations, optimizing warehouse space and operational efficiency.

What is Inventory Orchestration?

Inventory orchestration is an advanced process that integrates data from multiple inventory sources across warehouses, suppliers, and sales channels to enable real-time visibility and dynamic allocation of stock. Unlike traditional inventory management, which tracks stock levels and movements within isolated systems, inventory orchestration optimizes fulfillment by coordinating inventory flow, balancing supply and demand, and minimizing delays. This approach leverages AI-driven analytics and automation to enhance accuracy, reduce carrying costs, and improve customer satisfaction through smarter stock distribution.

Key Differences Between Inventory Management and Inventory Orchestration

Inventory Management focuses on tracking stock levels, orders, and replenishments within individual warehouses to maintain accurate inventory counts and avoid stockouts or overstocking. Inventory Orchestration integrates multiple inventory sources across various locations and sales channels, optimizing allocation and fulfillment processes to enhance overall supply chain efficiency. The key difference lies in Inventory Management's operational scope versus Inventory Orchestration's strategic role in synchronizing inventory flow across complex networks.

Core Processes in Inventory Management

Inventory Management centers on core processes such as stock tracking, demand forecasting, order replenishment, and accurate record-keeping to maintain optimal inventory levels. It involves continuous monitoring of stock movements, ensuring real-time visibility, and minimizing discrepancies through cycle counting and auditing. Efficient inventory management reduces holding costs and prevents stockouts by aligning supply with customer demand.

Essential Components of Inventory Orchestration

Inventory orchestration integrates real-time data, demand forecasting, and multi-location stock visibility to optimize supply chain efficiency. Essential components include centralized inventory control, dynamic allocation algorithms, and automated replenishment systems. These elements collectively enhance accuracy, reduce stockouts, and improve order fulfillment speed.

Benefits of Traditional Inventory Management

Traditional inventory management provides accurate stock tracking, reducing the risk of overstocking or stockouts in warehouses. It simplifies order fulfillment processes by maintaining clear visibility of inventory levels across storage locations. Effective inventory control through traditional methods supports cost efficiency by minimizing excess holding costs and optimizing replenishment cycles.

Advantages of Inventory Orchestration in Modern Warehousing

Inventory orchestration enhances warehouse operations by providing real-time visibility across multiple inventory sources, enabling dynamic allocation and reducing stockouts. It integrates advanced technologies like AI and IoT to optimize inventory levels, streamline order fulfillment, and improve supply chain responsiveness. Compared to traditional inventory management, inventory orchestration delivers greater accuracy, flexibility, and efficiency in managing complex, multi-channel warehousing environments.

Integrating Inventory Management Systems with Orchestration Tools

Integrating inventory management systems with orchestration tools enhances real-time visibility and accuracy across multiple warehouses, enabling seamless synchronization of stock levels and order fulfillment. This integration leverages APIs and cloud platforms to automate data exchange, reducing errors and improving responsiveness to demand fluctuations. Optimized inventory orchestration supports dynamic allocation, replenishment, and distribution strategies that maximize warehouse efficiency and minimize stockouts.

Challenges in Transitioning from Inventory Management to Orchestration

Transitioning from traditional inventory management to inventory orchestration presents challenges such as integrating disparate data sources and achieving real-time visibility across multiple channels. Complexities arise in synchronizing inventory levels while maintaining accuracy amidst dynamic demand and supply fluctuations. Ensuring seamless communication between warehouse management systems (WMS), enterprise resource planning (ERP), and order fulfillment platforms requires robust technology infrastructure and skilled personnel.

Future Trends: The Evolution from Management to Orchestration in Warehousing

Inventory orchestration in warehousing leverages advanced AI and IoT technologies to create a dynamic, interconnected system that goes beyond traditional inventory management's static tracking and replenishment. Future trends emphasize seamless integration of real-time data from multiple sources, enabling predictive analytics and automated decision-making to optimize stock levels and reduce operational costs. This evolution transforms warehouses into adaptive ecosystems capable of responding swiftly to market fluctuations and supply chain disruptions.

Related Important Terms

Unified Inventory Visibility

Inventory management focuses on tracking stock levels, orders, and deliveries within individual warehouses, while inventory orchestration provides unified inventory visibility across multiple locations and channels, enabling real-time demand fulfillment and optimized resource allocation. Unified inventory visibility integrates data from various sources to enhance accuracy, reduce stockouts, and streamline warehouse operations through coordinated supply chain activities.

Intelligent Replenishment

Inventory management tracks stock levels and order fulfillment, while inventory orchestration leverages intelligent replenishment algorithms to optimize stock distribution across multiple locations in real-time. This approach reduces stockouts and excess inventory by dynamically adjusting reorder points based on demand forecasts and supply chain variability.

Dynamic Stock Allocation

Inventory management focuses on tracking stock levels and order fulfillment, while inventory orchestration enables dynamic stock allocation by integrating real-time data across multiple channels and locations. This approach optimizes inventory distribution, reduces stockouts, and enhances overall warehouse efficiency.

Multi-Echelon Inventory Optimization

Multi-Echelon Inventory Optimization enhances Inventory Management by strategically balancing stock levels across multiple storage locations, reducing overall inventory costs while meeting service targets. Inventory Orchestration integrates real-time data and automated decision-making to synchronize supply chains, improving responsiveness and efficiency beyond traditional inventory control methods.

Inventory Synchronization Layer

Inventory management monitors stock levels and order fulfillment within warehouses, ensuring accurate tracking of goods. In contrast, inventory orchestration leverages the inventory synchronization layer to unify data across multiple channels and locations, enabling real-time visibility and seamless coordination of inventory movement.

Demand-Driven Orchestration

Inventory management involves tracking stock levels and replenishment needs, while demand-driven inventory orchestration dynamically aligns stock distribution with real-time customer demand signals. This approach optimizes order fulfillment, reduces excess inventory, and enhances supply chain responsiveness across multiple warehouses.

Real-Time Inventory Control Tower

Real-time Inventory Control Tower enables centralized visibility and synchronization across multiple warehouses, optimizing inventory allocation, demand forecasting, and replenishment decisions. Inventory orchestration extends beyond traditional inventory management by integrating dynamic workflows and AI-driven insights to proactively manage stock levels and reduce stockouts or overstocks in complex supply chains.

Automated Inventory Routing

Automated inventory routing enhances traditional inventory management by dynamically coordinating stock movement across multiple warehouses, optimizing fulfillment speed and reducing holding costs. By leveraging real-time data and AI algorithms, inventory orchestration enables precise demand forecasting and seamless allocation, improving supply chain agility and minimizing stockouts.

Distributed Inventory Nodes

Inventory management focuses on tracking stock levels within individual warehouses to maintain accurate counts and prevent stockouts, while inventory orchestration coordinates distributed inventory nodes across multiple locations to optimize fulfillment and reduce lead times. Leveraging real-time data and automation, inventory orchestration enhances visibility and responsiveness in multi-node warehousing environments, driving efficiency in supply chain operations.

Adaptive Fulfillment Logic

Adaptive fulfillment logic enhances inventory management by dynamically coordinating stock levels, order priorities, and distribution channels in real-time. Inventory orchestration leverages this logic to optimize warehouse operations, reduce fulfillment times, and improve overall supply chain responsiveness.

Inventory Management vs Inventory Orchestration Infographic

industrydif.com

industrydif.com