Pallet racking offers a cost-effective and straightforward solution for high-density storage, allowing easy manual access to inventory. Automated Storage and Retrieval Systems (ASRS) improve efficiency by reducing labor costs and speeding up order fulfillment through mechanized handling and precise inventory control. Choosing between these depends on warehouse size, automation budget, and desired throughput rates.

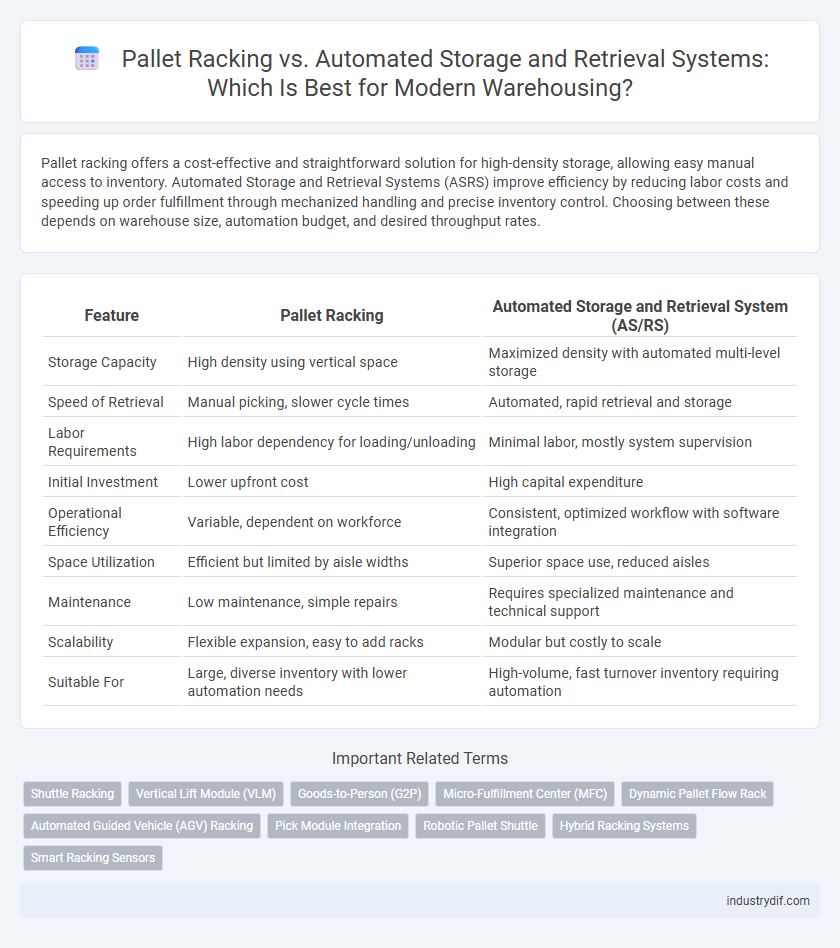

Table of Comparison

| Feature | Pallet Racking | Automated Storage and Retrieval System (AS/RS) |

|---|---|---|

| Storage Capacity | High density using vertical space | Maximized density with automated multi-level storage |

| Speed of Retrieval | Manual picking, slower cycle times | Automated, rapid retrieval and storage |

| Labor Requirements | High labor dependency for loading/unloading | Minimal labor, mostly system supervision |

| Initial Investment | Lower upfront cost | High capital expenditure |

| Operational Efficiency | Variable, dependent on workforce | Consistent, optimized workflow with software integration |

| Space Utilization | Efficient but limited by aisle widths | Superior space use, reduced aisles |

| Maintenance | Low maintenance, simple repairs | Requires specialized maintenance and technical support |

| Scalability | Flexible expansion, easy to add racks | Modular but costly to scale |

| Suitable For | Large, diverse inventory with lower automation needs | High-volume, fast turnover inventory requiring automation |

Introduction to Pallet Racking and AS/RS

Pallet racking systems provide a cost-effective and flexible solution for storing large volumes of palletized goods, offering easy access and efficient space utilization in warehouses. Automated Storage and Retrieval Systems (AS/RS) use robotic technology and computer-controlled systems to increase accuracy, speed, and inventory management while reducing labor costs and errors. Both technologies optimize warehouse storage but differ significantly in automation level, scalability, and initial investment.

Key Differences Between Pallet Racking and AS/RS

Pallet racking is a static storage solution designed for manual forklift access, offering straightforward setup and lower initial costs but limited space optimization and slower retrieval times. Automated Storage and Retrieval Systems (AS/RS) utilize robotics and conveyor technology to enhance storage density and speed, significantly improving inventory management accuracy and operational efficiency. AS/RS systems require higher capital investment and maintenance but provide scalable automation ideal for high-throughput warehousing environments.

Space Utilization and Storage Density

Pallet racking systems offer flexible storage solutions with moderate space utilization, allowing easy access to goods but often requiring wider aisles that reduce overall storage density. Automated Storage and Retrieval Systems (AS/RS) maximize space utilization by minimizing aisle widths and optimizing vertical space, significantly enhancing storage density. AS/RS systems enable higher throughput and storage capacity within a smaller warehouse footprint compared to traditional pallet racking.

Cost Comparison: Initial Investment & Long-term ROI

Pallet racking systems typically require a lower initial investment compared to Automated Storage and Retrieval Systems (AS/RS), making them more accessible for small to medium-sized warehouses. However, AS/RS delivers higher long-term ROI through enhanced space utilization, labor savings, and improved inventory accuracy that reduce operational costs over time. Companies must evaluate budget constraints against projected efficiency gains when choosing between traditional pallet racking and advanced automated solutions.

Scalability and Flexibility in Warehouse Operations

Pallet racking offers straightforward scalability by adding or rearranging racks to accommodate increased inventory, making it suitable for warehouses with variable storage needs. Automated Storage and Retrieval Systems (AS/RS) provide enhanced flexibility through programmable configurations that adapt to changing SKU profiles and order volumes without physical modifications. AS/RS enables dynamic warehouse operations with real-time inventory management, while pallet racking relies more on manual adjustments for scalability and flexibility.

Labor Requirements and Workforce Efficiency

Pallet racking systems demand significant manual labor for inventory handling, requiring a larger workforce to manage picking, stacking, and retrieval tasks. Automated Storage and Retrieval Systems (ASRS) minimize labor requirements by using robotics and software for fast, precise material movement, enhancing workforce efficiency and reducing human error. Implementing ASRS increases throughput while allowing employees to focus on higher-value tasks, optimizing overall warehouse productivity.

Integration with Warehouse Management Systems (WMS)

Pallet racking systems typically offer basic integration with Warehouse Management Systems (WMS), enabling straightforward inventory tracking and location management through barcode scanners or RFID tags. Automated Storage and Retrieval Systems (AS/RS) feature advanced WMS integration, allowing real-time data exchange for precise inventory control, order picking optimization, and seamless coordination of automated equipment. Enhanced WMS integration in AS/RS improves warehouse efficiency, accuracy, and throughput by synchronizing storage, retrieval, and inventory processes dynamically.

Safety Features and Risk Management

Pallet racking systems require regular inspections and proper load distribution to prevent structural failure and worker injuries, emphasizing manual safety protocols and hazard identification. Automated Storage and Retrieval Systems (AS/RS) integrate advanced safety features such as real-time collision detection, automated emergency stops, and controlled access zones, significantly reducing human error and accident risk. Implementing AS/RS enhances risk management by minimizing manual handling, improving inventory accuracy, and ensuring compliance with occupational safety standards.

Industry Applications and Use Cases

Pallet racking systems are widely used in industries requiring straightforward storage solutions for heavy goods, such as manufacturing, food and beverage, and retail warehouses, due to their cost-effectiveness and ease of installation. Automated Storage and Retrieval Systems (AS/RS) find critical applications in high-volume distribution centers, pharmaceutical warehouses, and electronics manufacturing, where precision, speed, and inventory accuracy are essential. Both systems enhance operational efficiency, but AS/RS excels in environments demanding tight space utilization and real-time inventory management.

Choosing the Right Solution for Your Warehouse

Pallet racking offers a cost-effective and flexible storage option ideal for warehouses with high SKU diversity and less frequent inventory turnover, maximizing vertical space efficiently. Automated Storage and Retrieval Systems (AS/RS) excel in environments requiring high throughput, precise inventory control, and labor reduction by integrating robotics and software for optimized picking and storage processes. Evaluating factors such as warehouse size, inventory characteristics, budget, and operational goals is critical to selecting the most suitable storage solution that enhances productivity and scalability.

Related Important Terms

Shuttle Racking

Shuttle racking combines high-density storage with automated shuttle technology to enhance warehouse efficiency, reducing labor costs and increasing throughput compared to traditional pallet racking systems. This system optimizes space utilization by enabling fast, selective access to pallets, making it ideal for warehouses with high pallet volumes and varying SKU sizes.

Vertical Lift Module (VLM)

Pallet racking provides cost-effective, high-density storage but is limited by manual picking speeds and vertical access constraints, whereas Vertical Lift Modules (VLMs) as an Automated Storage and Retrieval System optimize vertical space with mechanized trays, increasing picking accuracy and reducing labor costs by up to 40%. VLMs enhance inventory control through integrated software solutions, enabling faster retrieval times and efficient space utilization in warehouses with heights exceeding 15 feet.

Goods-to-Person (G2P)

Pallet racking systems provide traditional, static storage solutions that require manual picking, limiting efficiency in high-volume warehouses, while Automated Storage and Retrieval Systems (AS/RS) employing Goods-to-Person (G2P) technology significantly boost productivity by delivering items directly to operators, reducing travel time and errors. G2P AS/RS enhances inventory accuracy and optimizes space utilization, making it ideal for warehouses seeking faster order fulfillment and improved labor ergonomics.

Micro-Fulfillment Center (MFC)

Pallet racking in Micro-Fulfillment Centers (MFCs) offers high-density storage optimized for bulk inventory, while Automated Storage and Retrieval Systems (AS/RS) enhance picking speed and accuracy through robotics and software integration. AS/RS reduces labor costs and footprint, making it ideal for MFCs requiring rapid order fulfillment and scalability.

Dynamic Pallet Flow Rack

Dynamic Pallet Flow Rack enhances warehousing efficiency by utilizing gravity rollers for FIFO inventory management, reducing labor costs and improving storage density compared to traditional pallet racking. Automated Storage and Retrieval Systems (AS/RS) further optimize operations through robotic automation and real-time data integration, but Dynamic Pallet Flow Racks offer a cost-effective, high-throughput solution for medium to high-volume pallet handling.

Automated Guided Vehicle (AGV) Racking

Automated Guided Vehicle (AGV) racking enhances warehouse efficiency by integrating robotic mobility with dynamic storage solutions, reducing labor costs and increasing retrieval speed compared to traditional pallet racking. AGV racking systems optimize space utilization and inventory management through real-time data analytics and precise automated transport, enabling seamless handling of high-density, high-throughput environments.

Pick Module Integration

Pallet racking systems offer scalable storage solutions with manual or semi-automated picking processes, while Automated Storage and Retrieval Systems (AS/RS) integrate advanced pick module technologies to enhance order accuracy and throughput. AS/RS pick modules optimize space utilization and reduce labor costs by automating inventory retrieval, enabling faster cycle times and improved warehouse efficiency.

Robotic Pallet Shuttle

Robotic Pallet Shuttle systems enhance pallet racking by enabling high-density storage with automated, efficient retrieval that reduces labor costs and increases throughput in warehouses. These systems integrate seamlessly with existing pallet racking, optimizing space utilization and accelerating inventory management compared to traditional manual handling or conventional automated storage and retrieval systems (AS/RS).

Hybrid Racking Systems

Hybrid racking systems combine the high-density storage advantages of pallet racking with the efficiency and precision of automated storage and retrieval systems (AS/RS), optimizing space utilization and inventory management in modern warehouses. These integrated solutions reduce labor costs and increase throughput by enabling seamless transitions between manual pallet handling and automated processes.

Smart Racking Sensors

Smart racking sensors in pallet racking systems enhance inventory accuracy and real-time monitoring by detecting load weight, position, and environmental conditions, minimizing human error and optimizing space utilization. Automated Storage and Retrieval Systems (AS/RS) integrate advanced sensors with robotics for precise, high-speed material handling, improving operational efficiency and reducing labor costs in warehouse management.

Pallet Racking vs Automated Storage and Retrieval System Infographic

industrydif.com

industrydif.com