Storage racks offer traditional, open shelving systems ideal for bulk storage and easy access of large or irregularly shaped items, maximizing floor space through customizable levels. Vertical Lift Modules (VLMs) enhance storage density by utilizing automated, vertically stacked trays that deliver items directly to the operator, improving picking speed and reducing labor. Choosing between storage racks and VLMs depends on inventory size, space constraints, and the need for automation to optimize warehouse efficiency.

Table of Comparison

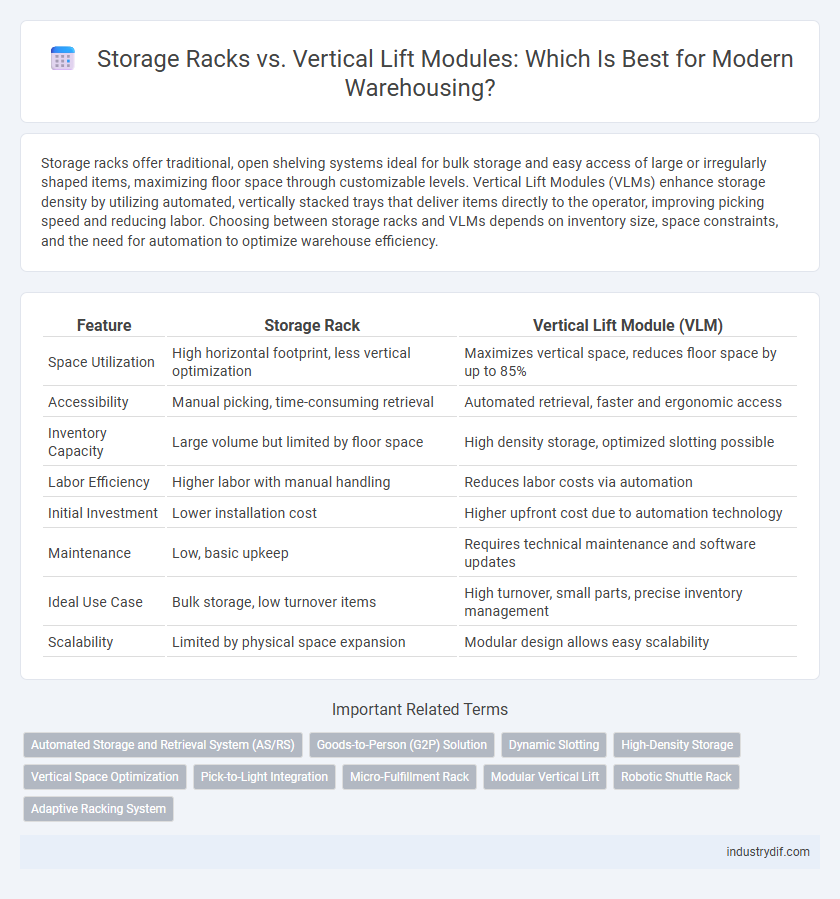

| Feature | Storage Rack | Vertical Lift Module (VLM) |

|---|---|---|

| Space Utilization | High horizontal footprint, less vertical optimization | Maximizes vertical space, reduces floor space by up to 85% |

| Accessibility | Manual picking, time-consuming retrieval | Automated retrieval, faster and ergonomic access |

| Inventory Capacity | Large volume but limited by floor space | High density storage, optimized slotting possible |

| Labor Efficiency | Higher labor with manual handling | Reduces labor costs via automation |

| Initial Investment | Lower installation cost | Higher upfront cost due to automation technology |

| Maintenance | Low, basic upkeep | Requires technical maintenance and software updates |

| Ideal Use Case | Bulk storage, low turnover items | High turnover, small parts, precise inventory management |

| Scalability | Limited by physical space expansion | Modular design allows easy scalability |

Introduction to Storage Rack and Vertical Lift Module

Storage racks provide versatile, open shelving systems designed to store a wide range of goods efficiently, optimizing horizontal space in warehouses. Vertical Lift Modules (VLMs) utilize automated vertical storage with trays delivered directly to the operator, maximizing vertical space and improving retrieval speed. Both storage solutions enhance warehouse organization, but VLMs offer advanced automation for increased productivity in high-density environments.

Key Differences Between Storage Racks and VLMs

Storage racks provide open shelving for bulk storage, maximizing floor space with direct access but requiring manual retrieval, while Vertical Lift Modules (VLMs) use automated vertical storage and retrieval, significantly increasing storage density and reducing picking time. Storage racks are cost-effective for large, less frequently accessed items, whereas VLMs offer enhanced inventory control and security through automation and software integration. The choice depends on factors like item size, retrieval speed, and operational complexity in warehousing environments.

Space Utilization: Storage Rack vs VLM

Storage racks offer straightforward horizontal space utilization with customizable shelf heights, ideal for bulkier items but often limited by aisle width. Vertical Lift Modules (VLMs) maximize vertical space by automating item retrieval within a compact footprint, significantly increasing storage density. Compared to traditional racks, VLMs can improve space utilization by up to 85%, making them optimal for warehouses with limited floor area and high SKU counts.

Inventory Accessibility and Retrieval Efficiency

Storage racks provide straightforward visual access and easy retrieval for bulk items, ideal for high-volume, low-turnover inventory. Vertical Lift Modules (VLMs) maximize vertical space and use automated trays to enhance accessibility, significantly speeding up retrieval times for small to medium-sized items. VLMs improve inventory accuracy and reduce labor by minimizing walking and picking errors compared to traditional storage racks.

Safety Considerations in Storage Racks vs Vertical Lift Modules

Storage racks require regular inspections to ensure structural integrity and prevent collapse hazards, whereas vertical lift modules (VLMs) are designed with enclosed lifts that reduce risks of falling objects and operator injuries. Safety features in VLMs include automatic load locking and built-in safety interlocks, minimizing human error and accidents compared to the manual handling often involved in storage racks. While storage racks pose higher risks of overloading and improper stacking, VLMs offer enhanced protection through automated controls and ergonomic access.

Cost Comparison: Initial Investment and Maintenance

Storage racks typically require a lower initial investment compared to Vertical Lift Modules (VLMs), making them cost-effective for basic warehousing needs. Maintenance costs for storage racks are minimal, mainly involving occasional inspections and repairs, whereas VLMs demand regular technical servicing and software updates, increasing long-term expenses. While VLMs offer space optimization and automation benefits, their higher initial and maintenance costs should be carefully evaluated against budget constraints and operational goals.

Scalability and Flexibility in Warehousing Solutions

Storage racks offer scalable solutions by allowing easy expansion through modular additions, adapting to increasing inventory volumes with customizable shelf configurations. Vertical Lift Modules (VLMs) enhance flexibility by utilizing automated vertical space, optimizing footprint efficiency and enabling dynamic inventory management with rapid item retrieval. Combining scalable storage racks with VLMs can maximize overall warehouse capacity while supporting diverse product sizes and fluctuating order demands.

Automation Integration: Storage Rack vs VLM Capabilities

Storage racks offer basic automation integration primarily through compatibility with automated retrieval systems and conveyors, enabling efficient inventory management but limited dynamic adaptability. Vertical Lift Modules (VLMs) provide advanced automation capabilities with integrated robotic pick-and-place systems, real-time inventory tracking, and customizable storage configurations for high-density storage and rapid item retrieval. VLMs enhance operational efficiency by minimizing manual labor and maximizing space utilization compared to traditional storage racks.

Suitability for Different Product Types

Storage racks offer versatile support for bulky, heavy, or irregularly shaped products, making them ideal for pallets, large containers, and oversized goods. Vertical Lift Modules (VLMs) excel in handling small to medium-sized items requiring high-density storage and quick access, such as tools, components, and packaged goods. Selecting between storage racks and VLMs depends on product dimensions, weight, picking frequency, and space optimization needs within the warehouse.

Deciding the Right Solution for Your Warehouse Operations

Storage racks offer cost-effective, high-density storage ideal for large, bulky items and easy access in traditional warehouse layouts. Vertical Lift Modules (VLMs) maximize vertical space utilization with automated storage and retrieval, improving picking accuracy and reducing labor costs in high-throughput operations. Evaluating factors like inventory types, space constraints, throughput requirements, and budget helps determine whether conventional racks or VLM systems optimize operational efficiency and scalability.

Related Important Terms

Automated Storage and Retrieval System (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) using Vertical Lift Modules (VLMs) provide higher storage density and faster, more accurate order picking compared to traditional Storage Racks by utilizing vertical space and integrated automation technology. VLMs reduce labor costs and improve inventory control through real-time data tracking, while Storage Racks offer simpler installation and lower upfront costs but require more manual handling and space.

Goods-to-Person (G2P) Solution

Storage racks offer a traditional Goods-to-Person (G2P) solution by organizing inventory on multiple levels for manual picking, while Vertical Lift Modules (VLMs) automate the process, delivering items directly to the operator to enhance picking speed and accuracy. VLMs optimize space utilization up to 85% more than storage racks, reduce labor costs, and improve ergonomic conditions through automated storage and retrieval systems.

Dynamic Slotting

Storage racks provide static slotting with fixed locations, while Vertical Lift Modules (VLMs) enable dynamic slotting by automatically adjusting storage positions based on item size, demand frequency, and picking velocity, optimizing space utilization and retrieval efficiency. Dynamic slotting in VLMs reduces travel time and enhances inventory accuracy compared to traditional static racks, increasing overall warehouse throughput.

High-Density Storage

Storage racks offer high-density storage by maximizing floor space through multiple shelving levels, ideal for bulkier items, while Vertical Lift Modules (VLMs) enhance high-density storage with automated vertical retrieval systems that optimize cube utilization and reduce aisle space. VLMs improve inventory accuracy and picking speed, making them suitable for environments demanding compact, high-density storage combined with automation.

Vertical Space Optimization

Vertical Lift Modules (VLMs) maximize vertical space utilization by automating storage within compact, high-density drawer systems, allowing for up to 85% more usable storage capacity compared to traditional storage racks. VLMs reduce warehouse footprint and improve picking efficiency by retrieving items directly to the operator, optimizing both space and workflow in constrained environments.

Pick-to-Light Integration

Storage racks offer traditional shelving solutions with moderate pick-to-light integration, enabling basic visual picking guidance, while vertical lift modules (VLMs) provide fully automated, high-density storage with seamless pick-to-light systems that enhance accuracy and speed by delivering items directly to the operator. VLMs optimize picking efficiency and reduce errors through real-time inventory tracking and dynamic light indicators, making them superior for environments demanding rapid order fulfillment and high throughput.

Micro-Fulfillment Rack

Micro-fulfillment racks offer high-density storage solutions that maximize vertical space utilization compared to traditional storage racks, enhancing picking speed and accuracy in warehouses. Vertical lift modules deliver automated storage and retrieval, but micro-fulfillment racks provide a scalable, cost-effective alternative tailored for rapid order fulfillment in compact spaces.

Modular Vertical Lift

Modular Vertical Lift systems maximize warehouse space by utilizing vertical storage and automated retrieval, increasing efficiency compared to traditional storage racks. These systems offer customizable configurations, faster access times, and improved inventory management through integrated software solutions.

Robotic Shuttle Rack

Robotic Shuttle Racks offer dynamic storage solutions with automated shuttles that efficiently transport goods within high-density shelving, optimizing space utilization and improving picking speed compared to traditional storage racks. Unlike Vertical Lift Modules that rely on vertical conveyors, Robotic Shuttle systems provide scalable multi-level access and flexible SKU management, enhancing throughput in complex warehouse operations.

Adaptive Racking System

Adaptive racking systems offer scalable storage solutions that optimize warehouse space through adjustable shelf heights and modular components, outperforming traditional storage racks in flexibility and load management. Vertical Lift Modules provide automated vertical storage and retrieval, but adaptive racking enhances operational efficiency by allowing customization for varying product dimensions and dynamic inventory needs.

Storage Rack vs Vertical Lift Module Infographic

industrydif.com

industrydif.com