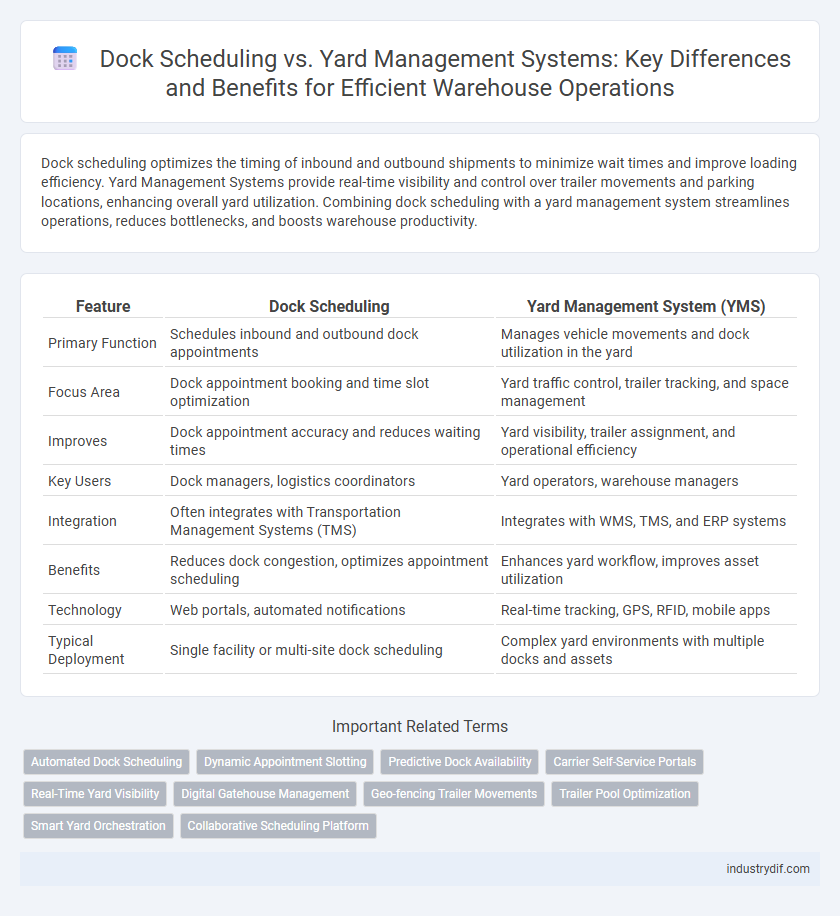

Dock scheduling optimizes the timing of inbound and outbound shipments to minimize wait times and improve loading efficiency. Yard Management Systems provide real-time visibility and control over trailer movements and parking locations, enhancing overall yard utilization. Combining dock scheduling with a yard management system streamlines operations, reduces bottlenecks, and boosts warehouse productivity.

Table of Comparison

| Feature | Dock Scheduling | Yard Management System (YMS) |

|---|---|---|

| Primary Function | Schedules inbound and outbound dock appointments | Manages vehicle movements and dock utilization in the yard |

| Focus Area | Dock appointment booking and time slot optimization | Yard traffic control, trailer tracking, and space management |

| Improves | Dock appointment accuracy and reduces waiting times | Yard visibility, trailer assignment, and operational efficiency |

| Key Users | Dock managers, logistics coordinators | Yard operators, warehouse managers |

| Integration | Often integrates with Transportation Management Systems (TMS) | Integrates with WMS, TMS, and ERP systems |

| Benefits | Reduces dock congestion, optimizes appointment scheduling | Enhances yard workflow, improves asset utilization |

| Technology | Web portals, automated notifications | Real-time tracking, GPS, RFID, mobile apps |

| Typical Deployment | Single facility or multi-site dock scheduling | Complex yard environments with multiple docks and assets |

Understanding Dock Scheduling

Dock scheduling streamlines the allocation of loading and unloading appointments at warehouse docks, optimizing the flow of inbound and outbound shipments. It minimizes wait times, reduces congestion, and enhances labor productivity by ensuring precise time slots for carriers. Integrating dock scheduling with warehouse management systems improves overall operational efficiency and customer satisfaction.

What is a Yard Management System?

A Yard Management System (YMS) optimizes the movement and storage of trailers and containers within a facility's yard, improving operational efficiency and reducing detention times. It provides real-time visibility into trailer locations, status updates, and appointment scheduling, enabling better coordination between docks and yard operations. Integrating a YMS with Dock Scheduling systems streamlines workflows by synchronizing yard activities with loading and unloading processes, minimizing delays and enhancing overall supply chain performance.

Key Features of Dock Scheduling Solutions

Dock scheduling solutions enhance operational efficiency by automating appointment booking, real-time load tracking, and resource allocation to minimize wait times and optimize dock utilization. These systems offer features such as dynamic scheduling adjustments, integration with warehouse management systems (WMS), and visibility into dock door availability, enabling precise planning and improved turnaround. Advanced dock scheduling tools support carrier self-scheduling portals, automated notifications, and analytics reporting to streamline freight flow and elevate overall supply chain performance.

Core Functions of Yard Management Systems

Yard Management Systems (YMS) optimize the coordination of trailer movements, gate check-ins, and dock door assignments, enhancing overall yard efficiency. Core functions include real-time tracking of assets, automated trailer scheduling, and yard space optimization, enabling faster turnaround times and reduced congestion. Unlike dock scheduling, which primarily manages dock appointments, YMS provides comprehensive visibility and control over the entire yard operations.

Comparing Dock Scheduling and Yard Management

Dock Scheduling optimizes appointment booking and resource allocation for inbound and outbound shipments, reducing wait times and improving dock door utilization. Yard Management Systems provide real-time visibility and control over trailer movements, yard assets, and storage locations, enhancing overall yard efficiency and safety. Integrating Dock Scheduling with Yard Management ensures seamless coordination between dock operations and yard activities, driving improved supply chain throughput.

Integration with Warehouse Management Systems

Dock scheduling optimizes appointment times for inbound and outbound shipments, improving loading bay utilization and reducing wait times. Yard management systems provide real-time visibility into trailer locations, gate activities, and yard asset status, enhancing operational flow across the facility. Seamless integration with Warehouse Management Systems (WMS) synchronizes inventory data, shipment status, and labor allocation, enabling precise coordination of warehouse and yard activities.

Benefits of Efficient Dock Scheduling

Efficient dock scheduling reduces wait times and congestion at warehouse docks, improving overall throughput and minimizing labor costs associated with loading and unloading. Streamlined scheduling ensures optimal use of dock resources, enhancing delivery accuracy and customer satisfaction by preventing delays. Integrating dock scheduling with yard management systems further improves visibility and coordination across the supply chain.

Advantages of Yard Management Implementation

Yard management implementation enhances operational efficiency by providing real-time visibility into trailer locations and statuses, reducing dwell times and streamlining gate processes. It improves resource allocation by optimizing yard space utilization and coordinating dock appointments, leading to faster load and unload cycles. Enhanced communication between drivers, yard operators, and warehouse staff minimizes errors and increases overall throughput in warehouse operations.

Choosing Between Dock Scheduling and Yard Management Systems

Choosing between Dock Scheduling and Yard Management Systems depends on your facility's operational priorities and scale. Dock Scheduling optimizes inbound and outbound freight appointments, reducing wait times and enhancing loading efficiency, ideal for facilities with high shipment volumes requiring precise dock coordination. Yard Management Systems provide a comprehensive overview of trailer locations, movements, and inventory across the yard, essential for large operations needing real-time asset tracking and improved yard traffic control.

Best Practices for Seamless Warehouse Operations

Efficient dock scheduling optimizes appointment times to reduce wait times and prevent bottlenecks, while yard management systems provide real-time visibility and control over trailer movements within the facility. Integrating these systems enables synchronized workflows, ensuring timely loading and unloading, and maximizing dock door utilization. Implementing automated notifications, standardized communication protocols, and predictive analytics enhances coordination between dock and yard operations, driving seamless warehouse performance.

Related Important Terms

Automated Dock Scheduling

Automated dock scheduling streamlines warehouse operations by optimizing appointment times and reducing wait times for carriers, enhancing loading dock productivity. Integrating this with a yard management system enables real-time visibility of asset movements, improving overall supply chain efficiency and reducing operational bottlenecks.

Dynamic Appointment Slotting

Dynamic Appointment Slotting optimizes dock scheduling by adjusting time slots in real-time based on incoming shipment data, reducing wait times and improving dock utilization. Yard Management Systems integrate this dynamic approach to coordinate trailer movements efficiently, enhancing overall warehouse throughput and minimizing congestion.

Predictive Dock Availability

Predictive dock availability enhances dock scheduling by using real-time data analytics and AI algorithms to forecast precise appointment times, reducing wait times and improving loading efficiency. Yard Management Systems integrate this predictive capability with asset tracking and gate management to optimize overall yard flow and minimize operational bottlenecks.

Carrier Self-Service Portals

Carrier self-service portals in dock scheduling streamline appointment booking and real-time updates, reducing wait times and enhancing dock door utilization. Yard management systems integrate these portals with asset tracking and gate control, optimizing carrier flow and improving overall warehouse throughput.

Real-Time Yard Visibility

Dock scheduling optimizes appointment times for efficient loading and unloading, while Yard Management Systems provide real-time yard visibility to track trailer locations, yard assets, and workflow status. Integrating real-time GPS and RFID technologies enhances yard management by reducing dwell times and improving asset utilization through precise, up-to-date information.

Digital Gatehouse Management

Digital gatehouse management streamlines dock scheduling by automating appointment bookings and real-time truck arrival tracking, reducing wait times and improving dock utilization. Integrating with yard management systems enhances overall operational visibility, enabling efficient gate access control and optimized trailer movements within the yard.

Geo-fencing Trailer Movements

Dock scheduling coordinates precise loading and unloading times to optimize operational flow, while yard management systems leverage geo-fencing technology to monitor and control trailer movements within designated zones, enhancing security and efficiency. Implementing geo-fencing in yard management enables real-time tracking of trailer locations, reducing delays and preventing unauthorized access by creating virtual boundaries around key areas.

Trailer Pool Optimization

Dock scheduling streamlines appointment bookings to reduce wait times and improve dock utilization, while yard management systems optimize trailer pool allocation by tracking trailer locations and statuses in real-time. Efficient trailer pool optimization minimizes dwell time and maximizes trailer availability, enhancing overall supply chain velocity and reducing operational costs.

Smart Yard Orchestration

Smart Yard Orchestration integrates dock scheduling and yard management system functionalities to optimize vehicle flow, reduce wait times, and improve asset utilization in warehouses. By leveraging IoT sensors, real-time data analytics, and AI-driven decision-making, it enables dynamic appointment scheduling, precise gate controls, and seamless coordination between dock doors and yard activities.

Collaborative Scheduling Platform

A Collaborative Scheduling Platform integrates Dock Scheduling with Yard Management System functionalities to optimize loading dock utilization and streamline trailer movements, reducing wait times and improving operational efficiency. By enabling real-time communication and coordinated scheduling between carriers, dock operators, and yard managers, it enhances resource allocation and accelerates turnaround in warehousing logistics.

Dock Scheduling vs Yard Management System Infographic

industrydif.com

industrydif.com