Inventory management involves tracking and controlling stock levels to meet current demand efficiently, minimizing carrying costs and avoiding stockouts. Predictive inventory uses advanced analytics and historical data to forecast future demand, enabling proactive stock replenishment and reducing excess inventory. Integrating predictive inventory with traditional management techniques enhances accuracy in supply chain planning and operational efficiency.

Table of Comparison

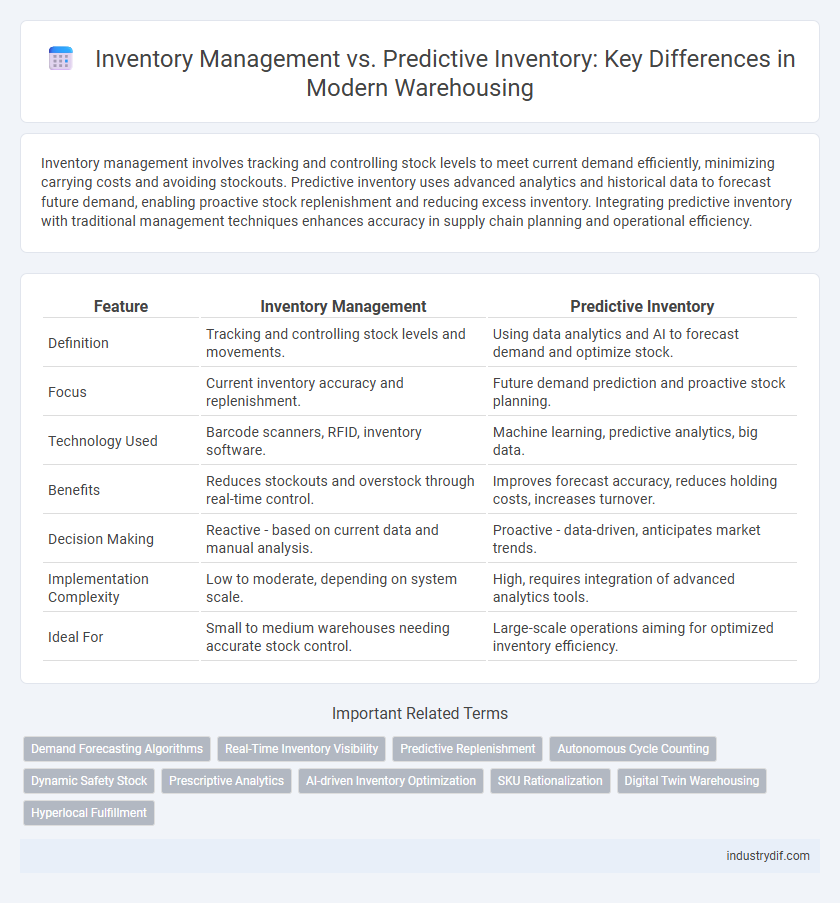

| Feature | Inventory Management | Predictive Inventory |

|---|---|---|

| Definition | Tracking and controlling stock levels and movements. | Using data analytics and AI to forecast demand and optimize stock. |

| Focus | Current inventory accuracy and replenishment. | Future demand prediction and proactive stock planning. |

| Technology Used | Barcode scanners, RFID, inventory software. | Machine learning, predictive analytics, big data. |

| Benefits | Reduces stockouts and overstock through real-time control. | Improves forecast accuracy, reduces holding costs, increases turnover. |

| Decision Making | Reactive - based on current data and manual analysis. | Proactive - data-driven, anticipates market trends. |

| Implementation Complexity | Low to moderate, depending on system scale. | High, requires integration of advanced analytics tools. |

| Ideal For | Small to medium warehouses needing accurate stock control. | Large-scale operations aiming for optimized inventory efficiency. |

Introduction to Inventory Management and Predictive Inventory

Inventory Management involves tracking and controlling stock levels to ensure optimal supply without overstocking or stockouts, using techniques like reorder points and safety stock calculations. Predictive Inventory utilizes advanced analytics and machine learning algorithms to forecast demand trends accurately, enabling proactive stock adjustments and reducing holding costs. Integrating predictive insights with traditional inventory management enhances operational efficiency and responsiveness in warehousing.

Defining Inventory Management in Warehousing

Inventory management in warehousing involves the systematic control of stock levels, ensuring accurate tracking, storage, and replenishment of goods to meet demand efficiently. It uses tools like barcode scanning, stock audits, and real-time data to minimize stockouts and overstock situations. Unlike predictive inventory, which forecasts future stock needs using historical data and analytics, traditional inventory management focuses on maintaining current inventory accuracy and operational flow.

What is Predictive Inventory?

Predictive inventory uses advanced data analytics and machine learning algorithms to forecast future inventory needs based on historical sales data, seasonal trends, and market demand patterns. This approach helps warehouses minimize stockouts and overstock situations by optimizing reorder points and quantities in real-time. Unlike traditional inventory management, predictive inventory proactively adapts to changing demand, improving accuracy and operational efficiency.

Key Differences Between Traditional and Predictive Inventory

Traditional inventory management relies on historical sales data and fixed reorder points to maintain stock levels, often resulting in overstocking or stockouts due to its reactive nature. Predictive inventory uses advanced analytics, machine learning algorithms, and real-time data to forecast demand more accurately, optimizing stock levels and reducing carrying costs. The key difference lies in predictive inventory's proactive approach to demand forecasting versus traditional inventory's reactive restocking methods.

Benefits of Inventory Management in the Warehousing Industry

Inventory management in warehousing ensures accurate stock control, reduces carrying costs, and enhances order fulfillment efficiency. By maintaining real-time visibility of inventory levels, warehouses can prevent stockouts and overstock situations, optimizing storage space and capital utilization. Effective inventory management also improves demand forecasting accuracy, streamlining replenishment processes and minimizing operational disruptions.

Advantages of Predictive Inventory for Warehouse Operations

Predictive inventory leverages advanced data analytics and machine learning algorithms to forecast demand with higher accuracy, reducing stockouts and excess inventory in warehouse operations. This proactive approach minimizes holding costs and optimizes space utilization, enhancing overall operational efficiency. Enhanced visibility into future inventory needs allows warehouses to streamline replenishment cycles and improve customer satisfaction through timely order fulfillment.

Technology’s Role in Inventory Management vs Predictive Inventory

Technology in inventory management leverages barcode scanning, RFID, and warehouse management systems (WMS) to streamline real-time tracking and stock control, reducing human error and improving accuracy. Predictive inventory utilizes advanced machine learning algorithms and AI-driven analytics to forecast demand patterns, optimize stock levels, and anticipate supply chain disruptions. Integration of IoT sensors and cloud computing enhances data visibility and decision-making, transforming traditional inventory management into proactive, predictive systems.

Challenges in Implementing Predictive Inventory Solutions

Implementing predictive inventory solutions in warehousing faces challenges such as data accuracy issues, which can lead to unreliable demand forecasts and stock imbalances. Integrating advanced analytics tools with existing warehouse management systems often requires significant IT infrastructure upgrades and staff training. Moreover, fluctuating market trends and supply chain disruptions complicate the development of effective predictive models, limiting their reliability and scalability.

Case Studies: Inventory Management vs Predictive Inventory in Practice

Case studies in warehousing reveal that traditional inventory management relies heavily on historical data and manual adjustments, often leading to stockouts or overstock situations. Predictive inventory techniques leverage machine learning algorithms and real-time analytics to forecast demand more accurately, resulting in a reduction of holding costs by up to 30% and improved order fulfillment rates. Companies implementing predictive inventory, such as Walmart and Amazon, report enhanced supply chain efficiency and responsiveness, demonstrating the practical advantages over conventional methods.

Future Trends in Warehousing: Toward Predictive Inventory Optimization

Predictive inventory optimization leverages advanced analytics and AI to forecast demand accurately, reducing carrying costs and stockouts in warehouses. Future trends emphasize integrating IoT sensors and machine learning algorithms for real-time inventory visibility and dynamic replenishment. This shift from traditional inventory management enhances operational efficiency and supports just-in-time inventory strategies in modern warehousing.

Related Important Terms

Demand Forecasting Algorithms

Inventory management relies on historical sales data and manual stock level adjustments, whereas predictive inventory leverages advanced demand forecasting algorithms such as machine learning models and time series analysis to anticipate future product demand with higher accuracy. These algorithms optimize stock replenishment, reduce holding costs, and enhance supply chain efficiency by analyzing patterns, seasonality, and external factors in real-time.

Real-Time Inventory Visibility

Inventory management relies on static stock data updated at intervals, whereas predictive inventory leverages real-time inventory visibility through IoT sensors and AI analytics to anticipate demand fluctuations and automate replenishment. This real-time insight reduces stockouts and overstock risks, optimizing warehouse efficiency and customer satisfaction.

Predictive Replenishment

Predictive replenishment leverages advanced algorithms and real-time data analytics to forecast inventory demand more accurately than traditional inventory management, reducing stockouts and excess inventory. By integrating machine learning and historical sales patterns, predictive inventory systems optimize stock levels, improve supply chain efficiency, and enhance warehouse operations.

Autonomous Cycle Counting

Autonomous cycle counting leverages predictive inventory technology to enhance accuracy and reduce manual labor compared to traditional inventory management methods. This innovative approach uses real-time data analytics and automated scanning systems to continuously update stock levels, minimizing discrepancies and optimizing warehouse efficiency.

Dynamic Safety Stock

Dynamic safety stock in predictive inventory management leverages real-time data and advanced analytics to continuously adjust buffer levels based on demand variability and supply chain disruptions, improving stock accuracy and reducing carrying costs. Traditional inventory management often uses static safety stock levels, which can lead to either stockouts or excess inventory, limiting responsiveness and operational efficiency in warehousing environments.

Prescriptive Analytics

Inventory management relies on historical data to track stock levels and reorder points, ensuring adequate supply without overstocking. Prescriptive analytics in predictive inventory goes beyond forecasting by recommending optimal order quantities and timing, leveraging machine learning algorithms to minimize costs and maximize efficiency.

AI-driven Inventory Optimization

AI-driven inventory optimization leverages machine learning algorithms to analyze historical sales data, seasonal trends, and demand variability, enabling precise inventory management that minimizes stockouts and excess stock. Predictive inventory systems enhance traditional inventory management by forecasting future demand patterns, optimizing reorder points, and automating replenishment processes to increase warehouse efficiency and reduce carrying costs.

SKU Rationalization

SKU rationalization optimizes inventory management by identifying and prioritizing high-performing stock-keeping units, reducing holding costs and minimizing obsolete inventory. Predictive inventory leverages advanced analytics and demand forecasting to enhance SKU rationalization, ensuring precise stock levels aligned with market trends and customer demand.

Digital Twin Warehousing

Digital Twin Warehousing leverages predictive inventory by simulating real-time warehouse operations to optimize stock levels and reduce holding costs, contrasting traditional inventory management that relies on static data tracking. This digital twin technology enables dynamic forecasting and scenario analysis, enhancing accuracy in demand prediction and resource allocation for more efficient inventory control.

Hyperlocal Fulfillment

Inventory management optimizes stock levels through systematic tracking and replenishment, while predictive inventory leverages data analytics and AI to forecast demand more accurately, enhancing hyperlocal fulfillment by reducing delivery times and minimizing stockouts. Hyperlocal fulfillment benefits from predictive inventory's capacity to anticipate regional consumer demand patterns, enabling warehouses to strategically position products closer to end-users for faster, cost-effective distribution.

Inventory Management vs Predictive Inventory Infographic

industrydif.com

industrydif.com