Inventory replenishment ensures products are restocked based on current stock levels and demand patterns, minimizing stockouts and overstock scenarios. Predictive stock optimization uses advanced analytics and machine learning algorithms to forecast future demand more accurately, enabling proactive inventory management. This approach reduces holding costs and improves service levels by aligning inventory closely with anticipated market needs.

Table of Comparison

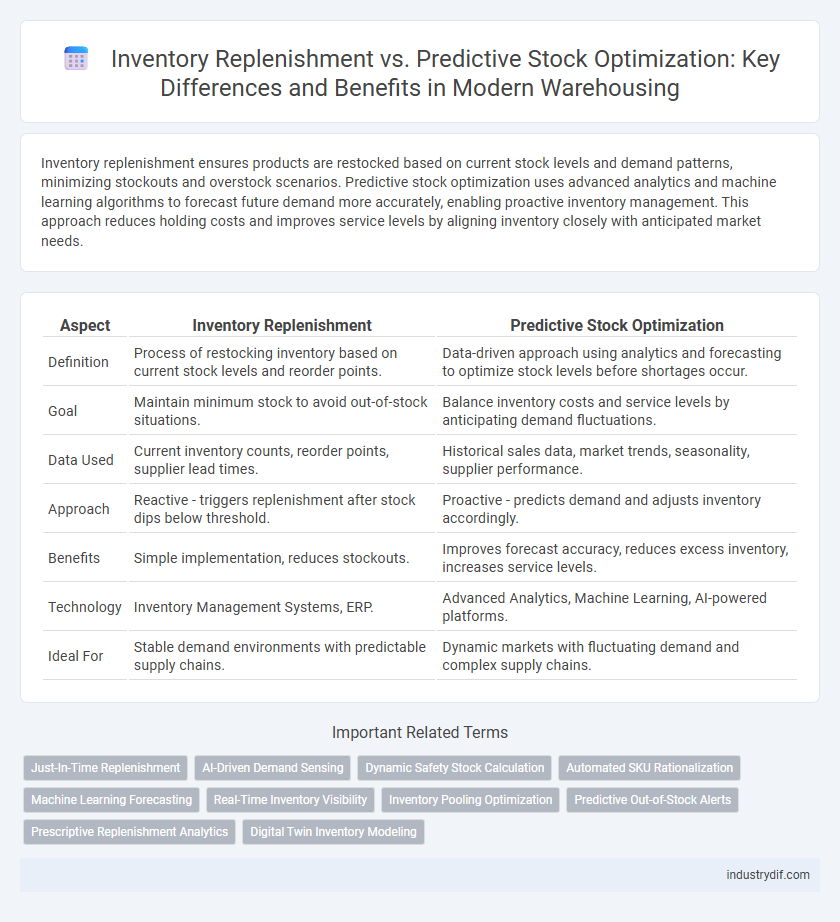

| Aspect | Inventory Replenishment | Predictive Stock Optimization |

|---|---|---|

| Definition | Process of restocking inventory based on current stock levels and reorder points. | Data-driven approach using analytics and forecasting to optimize stock levels before shortages occur. |

| Goal | Maintain minimum stock to avoid out-of-stock situations. | Balance inventory costs and service levels by anticipating demand fluctuations. |

| Data Used | Current inventory counts, reorder points, supplier lead times. | Historical sales data, market trends, seasonality, supplier performance. |

| Approach | Reactive - triggers replenishment after stock dips below threshold. | Proactive - predicts demand and adjusts inventory accordingly. |

| Benefits | Simple implementation, reduces stockouts. | Improves forecast accuracy, reduces excess inventory, increases service levels. |

| Technology | Inventory Management Systems, ERP. | Advanced Analytics, Machine Learning, AI-powered platforms. |

| Ideal For | Stable demand environments with predictable supply chains. | Dynamic markets with fluctuating demand and complex supply chains. |

Introduction to Inventory Replenishment and Predictive Stock Optimization

Inventory replenishment involves restocking products based on historical sales data and predefined reorder points to maintain adequate stock levels in warehouses. Predictive stock optimization uses advanced analytics and machine learning algorithms to forecast demand more accurately, reducing stockouts and overstock situations. This approach enhances supply chain efficiency by aligning inventory levels with real-time market trends and customer purchasing behavior.

Key Differences Between Replenishment and Stock Optimization

Inventory replenishment focuses on restoring stock levels based on predefined thresholds and historical sales data, ensuring products remain available. Predictive stock optimization uses advanced analytics and machine learning algorithms to forecast demand more accurately, adjusting inventory proactively to minimize excess stock and stockouts. The key difference lies in replenishment's reactive nature versus predictive optimization's proactive, data-driven approach to inventory management.

Traditional Inventory Replenishment Methods Explained

Traditional inventory replenishment methods rely on fixed reorder points and safety stock levels based on historical demand data and lead times, often leading to overstocking or stockouts. These methods typically use periodic review systems where inventory is checked at regular intervals, triggering replenishment orders once inventory falls below predetermined thresholds. Despite their simplicity, traditional approaches lack the adaptability and real-time responsiveness offered by predictive stock optimization techniques driven by advanced analytics and machine learning.

The Science Behind Predictive Stock Optimization

Predictive stock optimization leverages advanced algorithms and machine learning models to analyze historical sales data, seasonal trends, and external factors, enabling accurate demand forecasting. Unlike traditional inventory replenishment that relies on fixed reorder points, this science-driven approach dynamically adjusts stock levels to minimize holding costs and stockouts. Integration of real-time data and predictive analytics enhances warehouse efficiency by ensuring optimal inventory availability tailored to fluctuating market demands.

Advantages of Predictive Stock Optimization Over Replenishment

Predictive stock optimization leverages advanced analytics and machine learning to forecast demand accurately, reducing stockouts and excess inventory compared to traditional inventory replenishment methods. This approach enables dynamic adjustment of stock levels based on real-time data, improving warehouse efficiency and minimizing holding costs. By anticipating market trends and seasonality, predictive stock optimization enhances service levels and supports proactive supply chain management.

Technology's Role in Modern Inventory Management

Advanced technology in warehousing revolutionizes inventory replenishment by utilizing real-time data analytics and automated systems to accurately forecast demand and streamline stock levels. Predictive stock optimization leverages machine learning algorithms to analyze historical sales patterns, seasonal trends, and external factors, enabling proactive inventory decisions that minimize overstock and stockouts. Integration of IoT sensors and cloud computing enhances visibility and responsiveness, driving efficiency and cost savings in modern inventory management.

Data Requirements for Effective Stock Optimization

Inventory replenishment relies on historical sales and basic stock level data to trigger restocking orders, whereas predictive stock optimization demands comprehensive datasets, including real-time sales trends, seasonality patterns, supplier lead times, and demand forecasts. Advanced algorithms utilize this rich data to minimize stockouts and excess inventory by accurately anticipating future demand fluctuations. Effective stock optimization hinges on integrating diverse data sources to enable precise decision-making and maintain optimal inventory levels.

Challenges in Transitioning from Replenishment to Optimization

Transitioning from traditional inventory replenishment to predictive stock optimization presents challenges such as integrating advanced data analytics and machine learning algorithms into existing warehouse management systems. Companies often face data quality and real-time visibility issues that hinder accurate demand forecasting required for optimization. Additionally, organizational resistance to change and the need for employee upskilling slow the adoption of predictive methodologies over conventional replenishment approaches.

Best Practices for Implementing Predictive Stock Systems

Implementing predictive stock optimization in warehousing requires integrating advanced analytics and machine learning algorithms to accurately forecast demand and adjust inventory levels dynamically. Best practices include leveraging real-time data from multiple sources, automating replenishment processes to reduce lead times, and continuously monitoring system performance to refine predictive models. Ensuring seamless communication between inventory management software and warehouse operations enhances stock accuracy and prevents stockouts or overstocking.

Future Trends in Warehousing: Toward Smart Inventory Management

Inventory replenishment traditionally relies on fixed reorder points and manual forecasting, often leading to stockouts or excess inventory. Predictive stock optimization utilizes AI and machine learning algorithms to analyze historical data and real-time demand patterns, enabling precise stock level adjustments. Future trends in warehousing emphasize smart inventory management through automated data-driven decisions, reducing costs and improving service levels with enhanced accuracy and agility.

Related Important Terms

Just-In-Time Replenishment

Just-In-Time (JIT) Replenishment minimizes inventory holding costs by synchronizing stock arrivals with demand, reducing waste and storage needs. Unlike traditional inventory replenishment, predictive stock optimization uses real-time data and algorithms to forecast precise restocking requirements, enhancing efficiency and preventing stockouts.

AI-Driven Demand Sensing

AI-driven demand sensing enhances inventory replenishment by analyzing real-time sales data, seasonal trends, and market fluctuations to predict stock requirements with higher accuracy. Predictive stock optimization leverages machine learning algorithms to minimize stockouts and overstock, ensuring efficient warehouse operations and cost savings.

Dynamic Safety Stock Calculation

Dynamic safety stock calculation enhances inventory replenishment by continuously adjusting buffer levels based on real-time demand variability and lead time fluctuations, minimizing stockouts and excess inventory. Predictive stock optimization leverages advanced algorithms and machine learning to forecast future demand patterns, enabling more accurate and efficient inventory levels that align closely with actual consumption trends.

Automated SKU Rationalization

Automated SKU rationalization enhances inventory replenishment by analyzing sales data, demand patterns, and supply chain variables to eliminate slow-moving or redundant stock, optimizing SKU assortment for warehouse efficiency. Predictive stock optimization leverages machine learning algorithms to forecast demand more accurately, reducing stockouts and overstock while ensuring the right inventory levels align with customer needs and seasonality.

Machine Learning Forecasting

Inventory replenishment relies on historical sales data to trigger restocking, often leading to reactive decisions and stockouts. Predictive stock optimization leverages machine learning forecasting algorithms to analyze complex demand patterns, enabling proactive inventory adjustments that minimize costs and improve service levels.

Real-Time Inventory Visibility

Real-time inventory visibility enhances inventory replenishment by providing accurate stock levels and demand data, enabling timely restocking and minimizing stockouts. Predictive stock optimization leverages this real-time data with advanced analytics and machine learning to forecast demand trends, optimize inventory levels, and reduce holding costs.

Inventory Pooling Optimization

Inventory replenishment ensures stock availability by restocking items based on historical sales data, while predictive stock optimization leverages advanced analytics and machine learning to forecast demand more accurately, significantly enhancing inventory pooling optimization. Optimizing inventory pooling reduces redundant stock across multiple warehouses, balances inventory levels efficiently, and minimizes holding costs by strategically distributing stock according to predicted regional demand patterns.

Predictive Out-of-Stock Alerts

Predictive Out-of-Stock Alerts leverage machine learning algorithms and real-time data analysis to forecast inventory shortages before they occur, enabling proactive replenishment and minimizing stockouts. Unlike traditional Inventory Replenishment, which relies on historical sales and fixed reorder points, predictive alerts optimize stock levels dynamically by analyzing demand patterns, lead times, and supply chain disruptions.

Prescriptive Replenishment Analytics

Prescriptive replenishment analytics leverages advanced algorithms to recommend optimal inventory restocking quantities and timings, surpassing traditional inventory replenishment methods by integrating real-time demand signals and supply chain constraints. This approach reduces stockouts and overstock scenarios, improving warehouse efficiency and customer satisfaction through data-driven, actionable insights that optimize stock levels proactively.

Digital Twin Inventory Modeling

Inventory replenishment relies on historical sales data and fixed reorder points to maintain stock levels, often leading to overstocking or stockouts. Digital twin inventory modeling in predictive stock optimization simulates real-time warehouse operations, enabling dynamic adjustments based on demand forecasts, supplier lead times, and supply chain disruptions for enhanced accuracy and efficiency.

Inventory Replenishment vs Predictive Stock Optimization Infographic

industrydif.com

industrydif.com