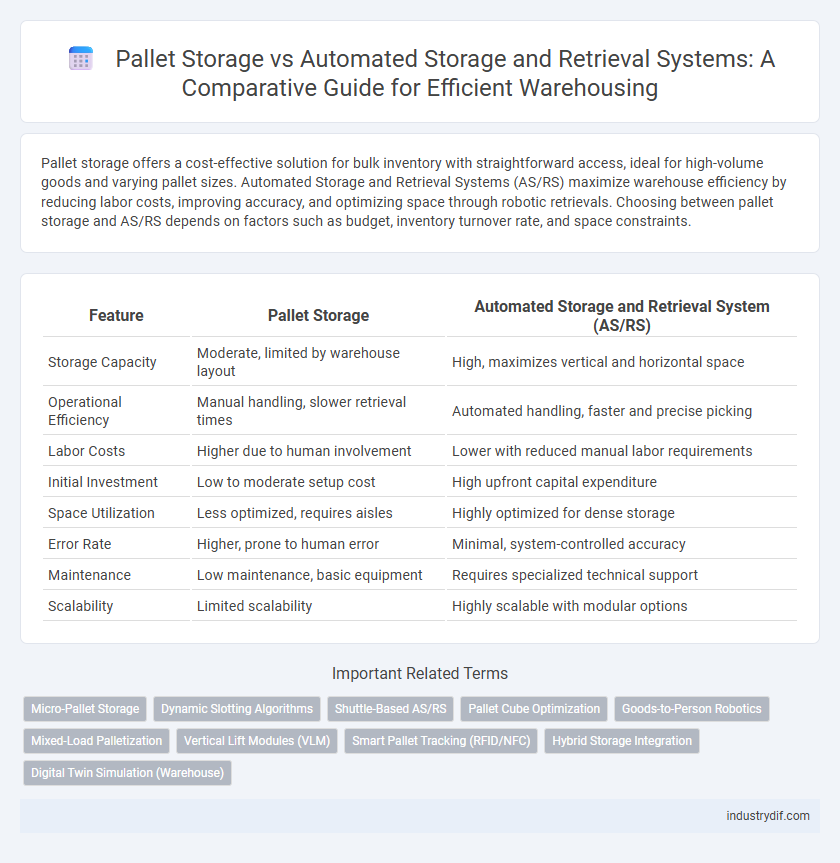

Pallet storage offers a cost-effective solution for bulk inventory with straightforward access, ideal for high-volume goods and varying pallet sizes. Automated Storage and Retrieval Systems (AS/RS) maximize warehouse efficiency by reducing labor costs, improving accuracy, and optimizing space through robotic retrievals. Choosing between pallet storage and AS/RS depends on factors such as budget, inventory turnover rate, and space constraints.

Table of Comparison

| Feature | Pallet Storage | Automated Storage and Retrieval System (AS/RS) |

|---|---|---|

| Storage Capacity | Moderate, limited by warehouse layout | High, maximizes vertical and horizontal space |

| Operational Efficiency | Manual handling, slower retrieval times | Automated handling, faster and precise picking |

| Labor Costs | Higher due to human involvement | Lower with reduced manual labor requirements |

| Initial Investment | Low to moderate setup cost | High upfront capital expenditure |

| Space Utilization | Less optimized, requires aisles | Highly optimized for dense storage |

| Error Rate | Higher, prone to human error | Minimal, system-controlled accuracy |

| Maintenance | Low maintenance, basic equipment | Requires specialized technical support |

| Scalability | Limited scalability | Highly scalable with modular options |

Overview of Pallet Storage Systems

Pallet storage systems provide a fundamental solution for warehousing by organizing goods on pallets using selective, drive-in, or push-back racking methods. These systems optimize space utilization and facilitate easy access to individual pallets, supporting efficient inventory management for bulk storage. Compared to automated storage and retrieval systems (AS/RS), pallet storage offers a cost-effective, scalable option ideal for businesses requiring straightforward, high-capacity storage without complex automation.

Introduction to Automated Storage and Retrieval Systems (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) revolutionize warehousing by utilizing computer-controlled systems for efficient pallet handling, inventory management, and space optimization. Unlike traditional pallet storage that relies on manual labor, AS/RS enables faster retrieval, reduced errors, and maximized storage density through precise automation. These systems integrate conveyors, cranes, and robotics to streamline operations, significantly increasing throughput and operational accuracy in modern distribution centers.

Key Differences Between Pallet Storage and AS/RS

Pallet storage systems utilize traditional shelving and racks to store goods, relying heavily on manual labor for loading and retrieval, which can limit speed and accuracy. Automated Storage and Retrieval Systems (AS/RS) employ computer-controlled systems, including cranes and conveyors, to enhance efficiency, reduce labor costs, and improve space utilization. Key differences include AS/RS's superior scalability, real-time inventory tracking, and higher throughput compared to conventional pallet storage.

Space Utilization: Pallet Storage vs AS/RS

Pallet storage typically requires more floor space due to wide aisles for forklifts, resulting in lower space utilization compared to Automated Storage and Retrieval Systems (AS/RS). AS/RS maximizes vertical space by using compact racking systems combined with automated cranes or shuttles, increasing storage density by up to 60%. This efficient use of cubic footage leads to significant capacity gains and reduces warehouse footprint requirements.

Labor Requirements and Efficiency

Pallet storage systems typically demand higher labor input for manual handling, loading, and retrieval, increasing operational costs and time. Automated Storage and Retrieval Systems (AS/RS) significantly reduce labor requirements by utilizing robotics and software controls for precise, fast storage operations. This automation enhances efficiency, minimizes human error, and accelerates throughput, making AS/RS a preferred choice for high-volume, time-sensitive warehousing environments.

Cost Comparison and ROI Analysis

Pallet storage systems typically involve lower initial capital expenditure but incur higher ongoing labor and space utilization costs, impacting overall operational efficiency. Automated Storage and Retrieval Systems (AS/RS) demand substantial upfront investment yet deliver significant long-term savings through reduced labor expenses, increased storage density, and optimized inventory accuracy. ROI analysis reveals AS/RS solutions generally achieve breakeven faster and provide superior cost benefits in high-volume, high-throughput warehouse environments.

Flexibility and Scalability in Warehousing

Pallet storage offers straightforward scalability by adding more racks, but it lacks the flexibility needed for diverse inventory sizes and frequent product rotation. Automated Storage and Retrieval Systems (AS/RS) provide enhanced flexibility through programmable controls that adapt to varying load types, optimizing space utilization and operational efficiency. AS/RS can scale vertically and horizontally with minimal physical footprint changes, enabling dynamic adjustments to warehouse capacity without extensive infrastructure modifications.

Safety Considerations and Risk Management

Pallet storage systems require strict adherence to load limits and proper stacking to prevent collapses, minimizing risks of injury and product damage. Automated Storage and Retrieval Systems (AS/RS) enhance safety by reducing human interaction with heavy loads and hazardous environments through mechanized operations and real-time monitoring. Implementing comprehensive risk management protocols, including regular equipment inspections and safety training, is critical for both systems to maintain workplace safety and operational efficiency.

Technology Integration and Automation Trends

Pallet storage relies on traditional racking systems optimized for manual or forklift handling, while Automated Storage and Retrieval Systems (AS/RS) integrate advanced robotics, sensors, and warehouse management software to enhance precision and throughput. The trend in warehousing technology is shifting towards AS/RS adoption due to its ability to reduce labor costs, improve space utilization, and enable real-time inventory tracking through IoT integration. Automation advancements like AI-driven algorithms and machine learning further optimize retrieval speeds and predictive maintenance, positioning AS/RS as a scalable solution in modern logistics operations.

Choosing the Right Storage Solution for Your Warehouse

Pallet storage offers a cost-effective and flexible option for warehouses with varying inventory sizes, allowing easy access and manual handling. Automated Storage and Retrieval Systems (AS/RS) enhance efficiency and space utilization by using robotics and software to manage high-density storage and fast throughput. Evaluating your warehouse's inventory turnover, space constraints, and labor costs helps determine whether traditional pallet storage or advanced AS/RS technology is the optimal storage solution.

Related Important Terms

Micro-Pallet Storage

Micro-pallet storage optimizes space by utilizing smaller pallets within automated storage and retrieval systems (AS/RS), increasing storage density and improving inventory accuracy compared to traditional pallet storage methods. AS/RS with micro-pallet capabilities enhances operational efficiency through faster retrieval times and reduced labor costs, making it ideal for high-throughput warehouses requiring precise material handling.

Dynamic Slotting Algorithms

Dynamic slotting algorithms in pallet storage optimize space utilization by continuously analyzing inventory turnover and product dimensions to assign storage locations, enhancing picking efficiency. Automated Storage and Retrieval Systems (AS/RS) leverage these algorithms with real-time data processing and robotics, drastically reducing labor costs and improving throughput in high-density warehouses.

Shuttle-Based AS/RS

Pallet storage offers simple, cost-effective solutions for bulk inventory with easy accessibility but occupies significant floor space and requires manual handling, while Shuttle-Based Automated Storage and Retrieval Systems (AS/RS) optimize space utilization up to 70%, increase throughput by 40%, and reduce labor costs by automating precise pallet movements within high-density racking. The Shuttle-Based AS/RS integrates robotic shuttles operating on multiple levels, enhancing speed and accuracy in inventory retrieval compared to traditional pallet racks, making it ideal for high-volume, dynamic warehouse environments.

Pallet Cube Optimization

Pallet cube optimization maximizes warehouse space by efficiently stacking and organizing pallets to fully utilize available volume, reducing wasted airspace and improving storage density compared to Automated Storage and Retrieval Systems (AS/RS), which prioritize speed and automation over space utilization. Advanced pallet cube optimization techniques can lead to higher storage capacity and cost savings by optimizing pallet dimensions, load configurations, and stacking patterns within traditional warehousing environments.

Goods-to-Person Robotics

Pallet storage maximizes space for bulk inventory, offering cost-efficient, high-density organization ideal for uniform goods, while Automated Storage and Retrieval Systems (ASRS) with Goods-to-Person robotics enhance picking accuracy, speed, and labor productivity by bringing items directly to operators, reducing travel time and error rates. Integrating ASRS solutions significantly optimizes warehouse throughput and operational efficiency in environments requiring dynamic inventory management and just-in-time order fulfillment.

Mixed-Load Palletization

Mixed-load palletization enhances warehouse flexibility by allowing diverse products to be stored on a single pallet, optimizing space utilization and reducing handling times. Automated Storage and Retrieval Systems (AS/RS) deliver precise inventory control and faster order fulfillment, outperforming traditional pallet storage in efficiency and accuracy for complex mixed-load scenarios.

Vertical Lift Modules (VLM)

Pallet storage offers high-density, bulk storage ideal for heavy or large items, while Automated Storage and Retrieval Systems (AS/RS) like Vertical Lift Modules (VLM) optimize space by utilizing vertical storage, enhancing picking speed and accuracy through mechanized trays. VLMs reduce labor costs and maximize warehouse footprint by delivering stored items directly to the operator, improving inventory control and workflow efficiency.

Smart Pallet Tracking (RFID/NFC)

Smart pallet tracking using RFID and NFC technologies enhances inventory accuracy and reduces manual errors in both pallet storage and Automated Storage and Retrieval Systems (AS/RS), enabling real-time location updates and seamless asset management. Integrating RFID/NFC with AS/RS optimizes warehouse throughput by automating pallet identification and movement, improving operational efficiency and minimizing downtime.

Hybrid Storage Integration

Hybrid storage integration combines the high-density efficiency of pallet storage with the precision and speed of automated storage and retrieval systems (AS/RS), enabling seamless inventory management and optimized space utilization. This approach enhances operational flexibility, reduces labor costs, and increases throughput in modern warehouse environments.

Digital Twin Simulation (Warehouse)

Digital Twin Simulation in warehouse management enables precise modeling and optimization of Pallet Storage and Automated Storage and Retrieval Systems (AS/RS), enhancing inventory accuracy and operational efficiency. Implementing digital twins allows real-time monitoring and predictive analysis, reducing downtime and improving throughput in both traditional pallet racking and advanced AS/RS environments.

Pallet Storage vs Automated Storage and Retrieval System Infographic

industrydif.com

industrydif.com