Inventory storage involves maintaining a fixed amount of stock in a dedicated warehouse, ensuring products are readily available for consistent demand and reducing lead times. On-demand warehousing offers flexible storage solutions by renting space as needed, optimizing costs and adapting to fluctuating inventory levels without long-term commitments. Choosing between the two depends on business size, inventory turnover rates, and the need for scalability.

Table of Comparison

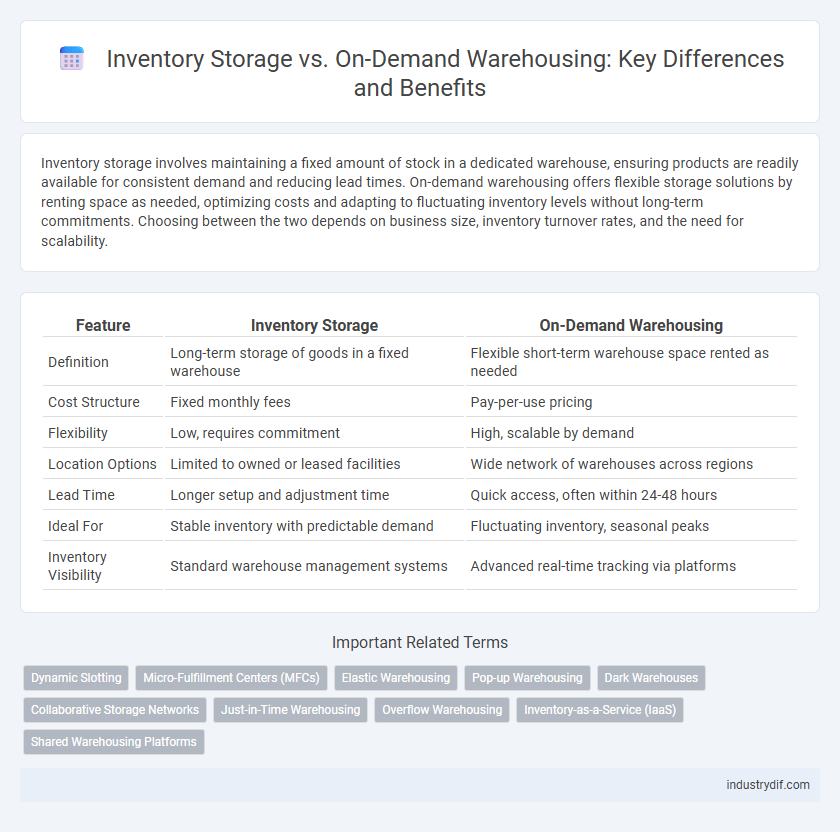

| Feature | Inventory Storage | On-Demand Warehousing |

|---|---|---|

| Definition | Long-term storage of goods in a fixed warehouse | Flexible short-term warehouse space rented as needed |

| Cost Structure | Fixed monthly fees | Pay-per-use pricing |

| Flexibility | Low, requires commitment | High, scalable by demand |

| Location Options | Limited to owned or leased facilities | Wide network of warehouses across regions |

| Lead Time | Longer setup and adjustment time | Quick access, often within 24-48 hours |

| Ideal For | Stable inventory with predictable demand | Fluctuating inventory, seasonal peaks |

| Inventory Visibility | Standard warehouse management systems | Advanced real-time tracking via platforms |

Introduction to Inventory Storage and On-demand Warehousing

Inventory storage involves maintaining a fixed amount of goods in a dedicated warehouse space, ensuring consistent availability and streamlined stock management. On-demand warehousing offers flexible, short-term storage solutions by connecting businesses with available warehouse capacity, optimizing space utilization and reducing overhead costs. Both approaches cater to different operational needs, with inventory storage emphasizing stability and on-demand warehousing prioritizing adaptability.

Key Differences Between Inventory Storage and On-demand Warehousing

Inventory storage involves the long-term holding of goods in dedicated warehouse spaces, providing consistent capacity and controlled environments tailored to specific product needs. On-demand warehousing offers flexible, short-term storage solutions that enable businesses to scale space dynamically based on fluctuating inventory levels without fixed commitments. The key differences lie in commitment duration, cost structure, and scalability, with inventory storage favoring predictability and stability while on-demand warehousing prioritizes agility and responsiveness to market changes.

Benefits of Traditional Inventory Storage

Traditional inventory storage offers consistent product availability, enabling businesses to fulfill orders quickly and maintain customer satisfaction. It allows for better control over stock levels and quality, reducing the risk of shortages or overstock situations. Additionally, long-term storage facilities often provide cost efficiencies through bulk storage rates and established infrastructure.

Advantages of On-demand Warehousing Solutions

On-demand warehousing solutions offer unmatched flexibility by allowing businesses to scale storage capacity according to real-time needs, eliminating the fixed costs associated with traditional inventory storage. This model enhances operational efficiency through rapid access to multiple warehouse locations, reducing transportation time and costs. Leveraging technology-driven platforms, on-demand warehousing provides data-driven inventory management and improved supply chain responsiveness.

Cost Comparison: Inventory Storage vs On-demand Warehousing

Inventory storage typically incurs fixed costs such as rent, utilities, and staffing, leading to higher expenses during periods of low demand. On-demand warehousing offers a flexible cost structure by charging based on actual space and time used, minimizing idle inventory costs and improving cash flow. Businesses can reduce overall warehousing expenditures by aligning storage capacity directly with fluctuating inventory needs through on-demand solutions.

Scalability and Flexibility in Warehousing Models

Inventory storage solutions offer fixed capacity optimized for predictable demand, ensuring stable cost structures but limited scalability during peak periods. On-demand warehousing models provide dynamic space allocation, enabling businesses to quickly scale storage capacity up or down based on real-time inventory fluctuations. This flexibility supports agile supply chain operations and reduces overhead costs by aligning warehouse usage with actual inventory needs.

Technology Integration in Inventory Storage and On-demand Warehousing

Inventory storage leverages advanced warehouse management systems (WMS) and automation technologies to optimize space utilization, track stock levels, and streamline order fulfillment processes in fixed facilities. On-demand warehousing integrates cloud-based platforms and IoT solutions to provide real-time warehouse availability, dynamic inventory allocation, and enhanced flexibility for short-term storage needs. Both approaches employ data analytics and AI-driven insights, but on-demand warehousing prioritizes seamless connectivity and rapid scalability through technology integration.

Choosing the Right Warehousing Solution for Your Business

Choosing the right warehousing solution depends on your business's inventory turnover rates and storage needs. Inventory storage offers dedicated space for bulk goods, ideal for consistent demand and long-term stock management, while on-demand warehousing provides scalable, flexible options that reduce overhead by renting space only when needed. Evaluating factors like cost efficiency, seasonal fluctuations, and order fulfillment speed ensures an optimized balance between storage capacity and operational agility.

Industry Use Cases: Inventory Storage vs On-demand Warehousing

Inventory storage in warehousing supports industries with consistent, high-volume product flow such as manufacturing, retail, and e-commerce, ensuring scalability and efficient stock management. On-demand warehousing caters to seasonal businesses, startups, and companies experiencing fluctuating inventory levels by providing flexible, short-term storage solutions that reduce fixed costs. Industry-specific use cases highlight inventory storage for long-term bulk management versus on-demand warehousing for dynamic, cost-effective space utilization.

Future Trends in Warehousing: What to Expect

Inventory storage is evolving with automation and AI-driven optimization enhancing space utilization and reducing costs, while on-demand warehousing gains momentum by offering flexible, scalable solutions powered by digital platforms and real-time data analytics. Future trends indicate a rise in hybrid models combining traditional inventory storage efficiency with the agility of on-demand warehousing to support just-in-time delivery and dynamic supply chain needs. Integration of IoT devices and advanced robotics will further enable predictive inventory management, minimizing downtime and maximizing throughput across warehousing operations.

Related Important Terms

Dynamic Slotting

Dynamic slotting in inventory storage optimizes warehouse efficiency by continuously reallocating goods based on demand patterns and product velocity, reducing picking time and enhancing space utilization. In contrast, on-demand warehousing leverages dynamic slotting to flexibly adapt storage locations for fluctuating seasonal inventory, improving responsiveness and minimizing costs associated with excess or idle space.

Micro-Fulfillment Centers (MFCs)

Micro-Fulfillment Centers (MFCs) enable efficient inventory storage by decentralizing stock closer to end consumers, reducing delivery times and enhancing order accuracy compared to traditional on-demand warehousing models. Leveraging automation and advanced software, MFCs optimize space usage and inventory turnover, supporting rapid fulfillment in high-density urban areas.

Elastic Warehousing

Elastic warehousing offers scalable inventory storage solutions that adapt to fluctuating demand, reducing the need for long-term fixed warehouse commitments and optimizing operational costs. By leveraging on-demand warehousing, businesses enhance supply chain flexibility and improve inventory turnover rates without excess storage capacity.

Pop-up Warehousing

Pop-up warehousing offers flexible, on-demand inventory storage solutions that adapt to fluctuating supply chain demands without the long-term commitments of traditional warehousing. This approach optimizes space utilization and reduces costs by enabling businesses to quickly scale storage capacity during peak seasons or unexpected surges in inventory.

Dark Warehouses

Dark warehouses, characterized by fully automated and unmanned inventory storage, optimize space utilization and reduce labor costs by relying on robotics and AI-driven systems for inventory management. Unlike on-demand warehousing, which offers flexible short-term storage solutions, dark warehouses emphasize continuous, high-efficiency operations suited for large-scale, time-sensitive inventory handling.

Collaborative Storage Networks

Collaborative storage networks optimize inventory management by pooling resources across multiple warehouses, reducing costs and improving space utilization compared to traditional inventory storage. On-demand warehousing leverages these networks to provide flexible, scalable storage solutions that adapt to fluctuating inventory needs without long-term commitments.

Just-in-Time Warehousing

Just-in-time (JIT) warehousing minimizes inventory holding costs by synchronizing stock arrivals with production schedules, reducing the need for extensive storage compared to traditional inventory storage methods. On-demand warehousing supports JIT by providing flexible, scalable space that adapts to fluctuating supply chain demands, enhancing efficiency and responsiveness.

Overflow Warehousing

Overflow warehousing efficiently addresses excess inventory by providing flexible, scalable storage solutions that prevent supply chain disruptions. Unlike traditional inventory storage, on-demand overflow warehousing offers real-time space allocation, reducing fixed costs and optimizing warehouse capacity during peak seasons.

Inventory-as-a-Service (IaaS)

Inventory-as-a-Service (IaaS) transforms warehousing by offering flexible, scalable inventory storage solutions that eliminate the need for long-term facility commitments, allowing businesses to pay only for the space they use. This on-demand warehousing model optimizes supply chain efficiency by enabling real-time inventory management and rapid adjustments to fluctuating market demands, contrasting with traditional fixed inventory storage.

Shared Warehousing Platforms

Shared warehousing platforms maximize space utilization by consolidating inventory from multiple businesses, reducing holding costs compared to traditional inventory storage that requires dedicated warehouse space. On-demand warehousing offers flexible storage solutions through these shared platforms, enabling scalable inventory management and real-time access to available warehouse capacity.

Inventory Storage vs On-demand Warehousing Infographic

industrydif.com

industrydif.com