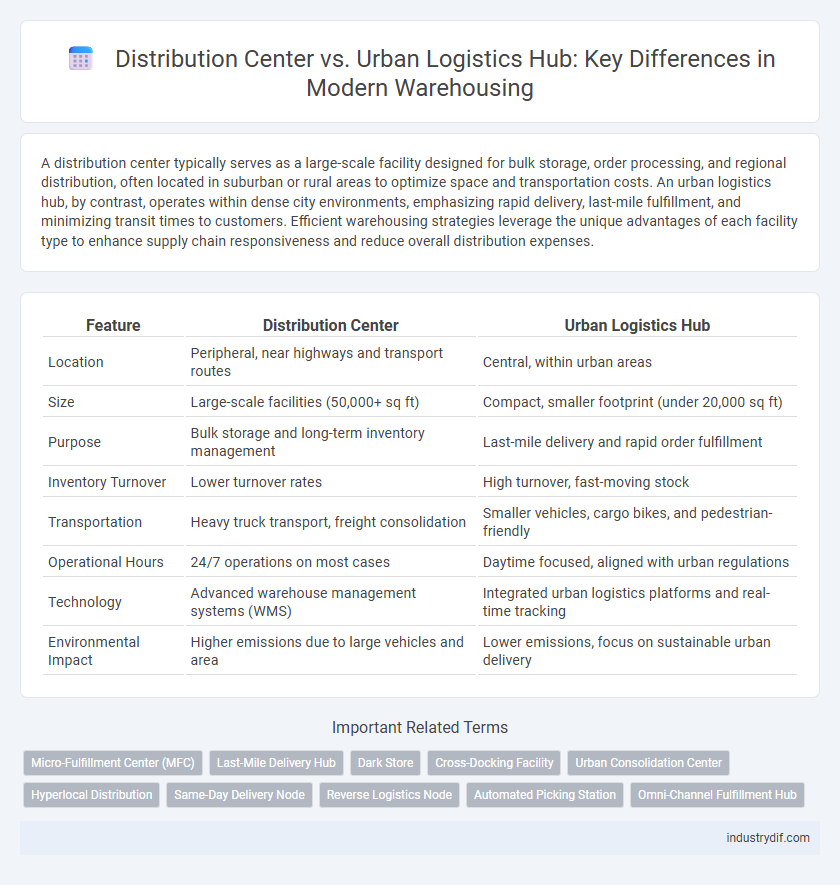

A distribution center typically serves as a large-scale facility designed for bulk storage, order processing, and regional distribution, often located in suburban or rural areas to optimize space and transportation costs. An urban logistics hub, by contrast, operates within dense city environments, emphasizing rapid delivery, last-mile fulfillment, and minimizing transit times to customers. Efficient warehousing strategies leverage the unique advantages of each facility type to enhance supply chain responsiveness and reduce overall distribution expenses.

Table of Comparison

| Feature | Distribution Center | Urban Logistics Hub |

|---|---|---|

| Location | Peripheral, near highways and transport routes | Central, within urban areas |

| Size | Large-scale facilities (50,000+ sq ft) | Compact, smaller footprint (under 20,000 sq ft) |

| Purpose | Bulk storage and long-term inventory management | Last-mile delivery and rapid order fulfillment |

| Inventory Turnover | Lower turnover rates | High turnover, fast-moving stock |

| Transportation | Heavy truck transport, freight consolidation | Smaller vehicles, cargo bikes, and pedestrian-friendly |

| Operational Hours | 24/7 operations on most cases | Daytime focused, aligned with urban regulations |

| Technology | Advanced warehouse management systems (WMS) | Integrated urban logistics platforms and real-time tracking |

| Environmental Impact | Higher emissions due to large vehicles and area | Lower emissions, focus on sustainable urban delivery |

Defining Distribution Centers and Urban Logistics Hubs

Distribution centers are large-scale warehouses designed to store and manage inventory for efficient order fulfillment and timely distribution across broad geographic regions. Urban logistics hubs are strategically located closer to city centers, focusing on rapid last-mile delivery to meet increasing demands for speed and sustainability in urban environments. Both play critical roles in supply chain optimization but differ primarily in size, location, and operational focus, with distribution centers supporting bulk storage and urban hubs emphasizing proximity and agility.

Key Functional Differences

Distribution centers primarily serve as large storage facilities focused on inventory management, bulk order fulfillment, and long-term storage, supporting wide geographic distribution. Urban logistics hubs specialize in last-mile delivery optimization, rapid sorting, and cross-docking activities to facilitate quick turnaround times within dense city environments. The key functional differences lie in scale, with distribution centers prioritizing bulk throughput efficiency, while urban logistics hubs emphasize speed, flexibility, and reduced urban congestion.

Location Strategies for Each Model

Distribution centers are typically located on the outskirts of metropolitan areas to leverage large land availability, lower costs, and easy access to major highways for efficient long-haul transportation. Urban logistics hubs prioritize inner-city locations to enable rapid last-mile delivery, reduce transit times, and address increasing demand for same-day fulfillment. Optimal location strategies balance transportation infrastructure, real estate costs, and proximity to end customers depending on the facility's role in the supply chain.

Inventory Management Approaches

Distribution centers emphasize bulk inventory storage and centralized order fulfillment using advanced warehouse management systems (WMS) for optimized stock control and replenishment cycles. Urban logistics hubs prioritize just-in-time inventory techniques and rapid turnover to accommodate frequent, small deliveries tailored to congested city environments. Both models rely heavily on real-time inventory tracking and data analytics to minimize stockouts and improve delivery accuracy.

Role in Last-Mile Delivery

Distribution centers serve as large-scale facilities designed for bulk storage and efficient order fulfillment, enabling the aggregation and sorting of goods before dispatch to regional or local delivery points. Urban logistics hubs are strategically located within metropolitan areas to facilitate rapid last-mile delivery by minimizing transit distances and enhancing delivery speed, often utilizing advanced technologies and multi-modal transport options. Together, these facilities optimize the supply chain by balancing inventory storage with agile, customer-focused distribution in densely populated urban markets.

Technology Integration and Automation

Distribution centers leverage advanced warehouse management systems (WMS) and robotics for automated sorting, inventory tracking, and efficient order fulfillment, optimizing large-scale storage and outbound logistics. Urban logistics hubs prioritize real-time data integration, IoT sensors, and last-mile delivery automation to enhance speed, accuracy, and sustainability within dense city environments. Both utilize AI-driven analytics and autonomous vehicles but differ in scale and complexity of their technology tailored to specific supply chain demands.

Scalability and Flexibility

Distribution centers offer high scalability with vast storage capacities designed for bulk inventory, enabling efficient long-term stock management. Urban logistics hubs prioritize flexibility through smaller footprints and proximity to city centers, facilitating rapid last-mile delivery and adapting quickly to fluctuating demand. Both models address warehousing needs, but scalability favors distribution centers, while urban hubs excel in agility and responsiveness.

Impact on Supply Chain Efficiency

Distribution centers streamline supply chain efficiency by consolidating inventory and optimizing bulk storage, enabling faster order fulfillment and reduced transportation costs. Urban logistics hubs enhance last-mile delivery effectiveness through proximity to end consumers, reducing delivery times and minimizing traffic congestion impacts. Combining both facilities strategically maximizes overall supply chain agility and responsiveness.

Environmental and Urban Planning Considerations

Distribution centers typically occupy large, peripheral sites designed for high-volume freight handling, often resulting in increased vehicle emissions and traffic congestion. Urban logistics hubs prioritize compact, multi-use spaces within city boundaries to reduce last-mile delivery distances, lowering carbon footprints and enabling sustainable mobility solutions like electric vehicles and cargo bikes. Both approaches require strategic urban planning to balance efficient goods movement with minimizing environmental impact and preserving livability in dense urban areas.

Choosing the Right Model for Your Business

Choosing between a Distribution Center and an Urban Logistics Hub depends on your supply chain needs, delivery speed requirements, and target customer base. Distribution Centers are ideal for large-scale inventory storage and regional fulfillment, while Urban Logistics Hubs prioritize last-mile delivery efficiency in congested metropolitan areas. Optimizing your warehousing strategy around these models enhances operational scalability and improves customer satisfaction through faster, cost-effective deliveries.

Related Important Terms

Micro-Fulfillment Center (MFC)

Micro-Fulfillment Centers (MFCs) within Urban Logistics Hubs offer rapid, localized inventory management and order fulfillment using automated systems, significantly reducing last-mile delivery times compared to traditional Distribution Centers. These compact facilities leverage advanced robotics and data analytics to optimize storage density and operational efficiency in urban areas, meeting the growing demand for same-day e-commerce delivery.

Last-Mile Delivery Hub

Distribution centers primarily serve as large-scale warehouses that store bulk inventory for regional or national distribution, while urban logistics hubs specialize in last-mile delivery by strategically positioning smaller facilities closer to dense urban populations, significantly reducing delivery times and transportation costs. Leveraging technology such as real-time tracking and route optimization, urban logistics hubs enhance operational efficiency and support sustainable delivery models in congested city environments.

Dark Store

Distribution centers primarily handle bulk storage and large-scale order fulfillment, while urban logistics hubs, especially dark stores, focus on rapid last-mile delivery within dense city areas; dark stores function as localized warehouses designed exclusively for online order picking, significantly reducing delivery times. These urban hubs optimize inventory placement and leverage proximity to consumers to enhance efficiency and meet growing e-commerce demands.

Cross-Docking Facility

Cross-docking facilities in distribution centers streamline product flow by minimizing storage time and reducing handling costs, making them ideal for large-scale, centralized warehousing operations. Urban logistics hubs leverage cross-docking to enhance last-mile delivery efficiency in congested city environments, improving speed and reducing transportation emissions.

Urban Consolidation Center

Urban Consolidation Centers (UCCs) streamline last-mile delivery by aggregating goods from multiple suppliers into a single, centralized hub located near urban areas, reducing traffic congestion and carbon emissions compared to traditional Distribution Centers. These urban logistics hubs enhance efficiency by enabling consolidated shipments and optimizing vehicle routes, which is critical for sustainable and cost-effective city logistics.

Hyperlocal Distribution

Distribution centers primarily handle bulk storage and regional order fulfillment, while urban logistics hubs specialize in hyperlocal distribution, enabling faster delivery within dense city environments. Hyperlocal distribution leverages advanced inventory management and last-mile delivery solutions to meet rising consumer demand for same-day or immediate shipments.

Same-Day Delivery Node

Distribution centers traditionally manage large volumes of inventory with extended storage capacity, optimizing regional fulfillment but often located on city outskirts, whereas urban logistics hubs specialize in rapid same-day delivery by positioning efficiently within dense metropolitan areas to reduce last-mile transit times. The same-day delivery node in urban logistics hubs leverages advanced technology and real-time data to expedite parcel sorting and dispatch, significantly enhancing speed and customer satisfaction in e-commerce and retail sectors.

Reverse Logistics Node

A distribution center primarily functions as a centralized facility for inbound storage and outbound order fulfillment, while an urban logistics hub specializes in last-mile delivery solutions, emphasizing proximity to dense consumer areas. As a reverse logistics node, the urban logistics hub streamlines returns processing and product redistribution within city environments, enhancing efficiency and reducing transportation costs.

Automated Picking Station

Automated picking stations in Distribution Centers enhance efficiency by handling high volumes of goods with precision, supporting bulk storage and long-term inventory management. Urban Logistics Hubs utilize compact automated picking systems designed for rapid order fulfillment and last-mile delivery, optimizing space constraints and reducing transit times within dense city environments.

Omni-Channel Fulfillment Hub

Distribution centers focus on large-scale inventory storage and efficient bulk order processing, while urban logistics hubs specialize in last-mile delivery and rapid fulfillment within dense metropolitan areas. Omni-channel fulfillment hubs combine these functions by integrating inventory management, cross-docking, and flexible order processing to support seamless multi-channel customer experiences.

Distribution Center vs Urban Logistics Hub Infographic

industrydif.com

industrydif.com