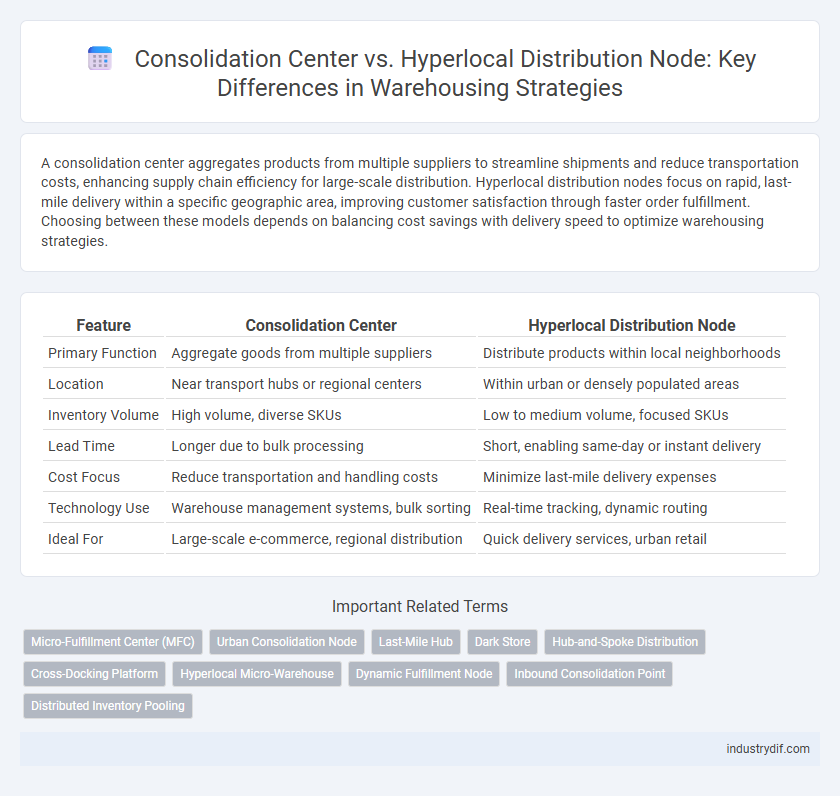

A consolidation center aggregates products from multiple suppliers to streamline shipments and reduce transportation costs, enhancing supply chain efficiency for large-scale distribution. Hyperlocal distribution nodes focus on rapid, last-mile delivery within a specific geographic area, improving customer satisfaction through faster order fulfillment. Choosing between these models depends on balancing cost savings with delivery speed to optimize warehousing strategies.

Table of Comparison

| Feature | Consolidation Center | Hyperlocal Distribution Node |

|---|---|---|

| Primary Function | Aggregate goods from multiple suppliers | Distribute products within local neighborhoods |

| Location | Near transport hubs or regional centers | Within urban or densely populated areas |

| Inventory Volume | High volume, diverse SKUs | Low to medium volume, focused SKUs |

| Lead Time | Longer due to bulk processing | Short, enabling same-day or instant delivery |

| Cost Focus | Reduce transportation and handling costs | Minimize last-mile delivery expenses |

| Technology Use | Warehouse management systems, bulk sorting | Real-time tracking, dynamic routing |

| Ideal For | Large-scale e-commerce, regional distribution | Quick delivery services, urban retail |

Definition of Consolidation Center

A consolidation center is a centralized facility where goods from multiple suppliers are aggregated, sorted, and combined into larger shipments for efficient distribution. This approach reduces transportation costs and enhances delivery speed by minimizing the number of trips between suppliers and distribution nodes. Consolidation centers play a critical role in streamlining the supply chain and improving inventory management before products reach hyperlocal distribution nodes.

Overview of Hyperlocal Distribution Node

A hyperlocal distribution node functions as a compact fulfillment hub designed to expedite last-mile delivery within a specific geographic area, reducing transit times and improving service speed. These nodes leverage real-time inventory data and proximity to densely populated urban centers to optimize stock availability and meet immediate consumer demand. Integration with advanced route planning and local courier networks enhances operational efficiency and minimizes delivery costs in hyperlocal warehousing strategies.

Key Operational Differences

Consolidation centers aggregate goods from multiple suppliers to optimize transportation by reducing shipping costs and improving load efficiency, typically handling bulk shipments for long-distance distribution. Hyperlocal distribution nodes focus on last-mile delivery within a confined geographic area, prioritizing speed and responsiveness to support immediate customer demand. Key operational differences include inventory management scale, with consolidation centers managing larger, diverse stock, while hyperlocal nodes maintain limited, high-turnover inventory for rapid order fulfillment.

Advantages of Consolidation Centers

Consolidation centers improve supply chain efficiency by aggregating goods from multiple suppliers, reducing transportation costs and minimizing shipment frequencies to retailers. Centralized inventory management at consolidation centers enables better demand forecasting, lowers stockouts, and enhances order accuracy. These centers support bulk handling and enable eco-friendly logistics by optimizing vehicle loads and decreasing carbon emissions across distribution networks.

Benefits of Hyperlocal Distribution Nodes

Hyperlocal distribution nodes enhance last-mile delivery speed by positioning inventory closer to end customers, reducing transit time and transportation costs. They improve service flexibility and customer satisfaction through quicker order fulfillment and real-time inventory visibility. Compared to traditional consolidation centers, hyperlocal nodes enable adaptive supply chain responsiveness in dense urban areas.

Impact on Inventory Management

Consolidation centers improve inventory management by aggregating products from multiple suppliers, reducing stock fragmentation and enabling bulk shipments that lower holding costs. Hyperlocal distribution nodes enhance inventory accuracy through real-time demand data, minimizing overstock and stockouts in localized markets. Both strategies optimize inventory turnover, but consolidation centers focus on centralized stock control while hyperlocal nodes prioritize agile, demand-driven replenishment.

Role in Last-Mile Delivery

A consolidation center aggregates shipments from multiple suppliers to optimize load capacity and reduce transportation costs before final dispatch, enhancing efficiency in last-mile delivery. In contrast, a hyperlocal distribution node is positioned closer to end customers, enabling rapid order fulfillment and real-time inventory availability for same-day or next-day delivery. Both facilities streamline last-mile logistics but serve distinct roles: consolidation centers optimize inbound freight, while hyperlocal nodes accelerate outbound delivery speed.

Cost Implications and Efficiency

Consolidation centers reduce transportation costs by aggregating shipments from multiple suppliers, optimizing freight efficiency through bulk handling and minimizing last-mile delivery expenses. Hyperlocal distribution nodes enhance delivery speed and customer satisfaction by strategically positioning inventory closer to end consumers, though they entail higher operational costs due to multiple localized facilities. Balancing these models involves assessing trade-offs between centralized cost savings and decentralized agility to optimize overall warehousing efficiency.

Scalability and Flexibility in Supply Chain

Consolidation centers streamline inbound shipments by aggregating goods from multiple suppliers, enhancing scalability through bulk handling and reducing transportation costs. Hyperlocal distribution nodes increase flexibility by enabling rapid fulfillment within localized markets, adapting swiftly to demand fluctuations and urban delivery constraints. Both models optimize supply chain efficiency, with consolidation centers supporting volume scalability and hyperlocal nodes enhancing agile last-mile delivery.

Choosing the Right Model for Your Business

Consolidation centers streamline inventory by aggregating products from multiple suppliers, reducing transportation costs and improving supply chain efficiency for businesses with widespread sourcing. Hyperlocal distribution nodes focus on rapid last-mile delivery within a constrained geographic area, ideal for companies prioritizing speed and customer proximity in urban markets. Selecting the right model depends on factors such as order volume, delivery timelines, geographic scope, and the balance between cost efficiency and service level expectations.

Related Important Terms

Micro-Fulfillment Center (MFC)

Micro-Fulfillment Centers (MFCs) serve as efficient hyperlocal distribution nodes that enable rapid order fulfillment by leveraging automation and proximity to end consumers, contrasting with consolidation centers that primarily aggregate inventory from multiple suppliers for bulk shipment. MFCs optimize last-mile delivery, reduce transportation costs, and enhance inventory turnover through real-time data integration and localized stock management.

Urban Consolidation Node

Urban Consolidation Nodes serve as strategic hubs in warehousing that aggregate shipments from multiple suppliers, significantly reducing urban freight traffic and delivery times compared to traditional consolidation centers. These hyperlocal distribution nodes optimize last-mile logistics by facilitating efficient, sustainable deliveries within dense city environments while minimizing environmental impact and operational costs.

Last-Mile Hub

A consolidation center aggregates shipments from multiple suppliers to streamline deliveries, reducing transportation costs and enhancing efficiency in last-mile logistics. In contrast, a hyperlocal distribution node is strategically positioned closer to end customers, enabling faster delivery times and greater flexibility in handling small, high-frequency orders for last-mile hubs.

Dark Store

Dark stores function as hyperlocal distribution nodes, enabling rapid order fulfillment by serving nearby customers directly from inventory-rich locations. Consolidation centers aggregate shipments from multiple suppliers to optimize logistics efficiency but lack the immediate proximity and speed advantages inherent to dark stores.

Hub-and-Spoke Distribution

A consolidation center aggregates goods from multiple suppliers to streamline shipments before they reach regional hubs, optimizing transportation costs within a hub-and-spoke distribution model. Hyperlocal distribution nodes operate closer to end consumers, enabling faster last-mile delivery and increased responsiveness in the hub-and-spoke network.

Cross-Docking Platform

A consolidation center organizes incoming shipments from multiple suppliers to prepare combined loads for efficient dispatch, reducing last-mile delivery costs. In contrast, a hyperlocal distribution node utilizes a cross-docking platform to immediately transfer goods from inbound to outbound vehicles, minimizing storage time and accelerating delivery within localized urban areas.

Hyperlocal Micro-Warehouse

Hyperlocal micro-warehouses operate as compact consolidation centers strategically located within urban areas to facilitate rapid order fulfillment and delivery, reducing last-mile transit times and logistics costs. These nodes enhance inventory localization, support same-day delivery, and improve service levels by closely aligning stock availability with immediate consumer demand.

Dynamic Fulfillment Node

Dynamic fulfillment nodes integrate the benefits of consolidation centers and hyperlocal distribution nodes by enabling real-time inventory aggregation and rapid last-mile delivery within localized markets. These nodes optimize warehousing operations through adaptive inventory management, reducing transit times and improving order accuracy in omnichannel fulfillment strategies.

Inbound Consolidation Point

Inbound consolidation points in warehousing streamline the aggregation of shipments from multiple suppliers into a single, organized load, reducing transportation costs and improving inventory accuracy. Consolidation centers focus on merging inbound goods for long-distance distribution, whereas hyperlocal distribution nodes cater to rapid, last-mile deliveries within localized areas.

Distributed Inventory Pooling

Distributed inventory pooling in consolidation centers centralizes stock from multiple suppliers to optimize large-scale order fulfillment, reducing transportation costs and improving supply chain efficiency. Hyperlocal distribution nodes leverage distributed inventory across local markets to enable faster delivery and better responsiveness, prioritizing proximity over volume in warehousing strategies.

Consolidation center vs Hyperlocal distribution node Infographic

industrydif.com

industrydif.com