Manual handling in warehousing involves workers physically picking and moving items, which can be labor-intensive and prone to human error. Goods-to-person systems automate the retrieval process by bringing products directly to the operator, significantly increasing speed, accuracy, and reducing workplace injuries. This shift enhances overall efficiency and optimizes inventory management by minimizing travel time and improving order fulfillment rates.

Table of Comparison

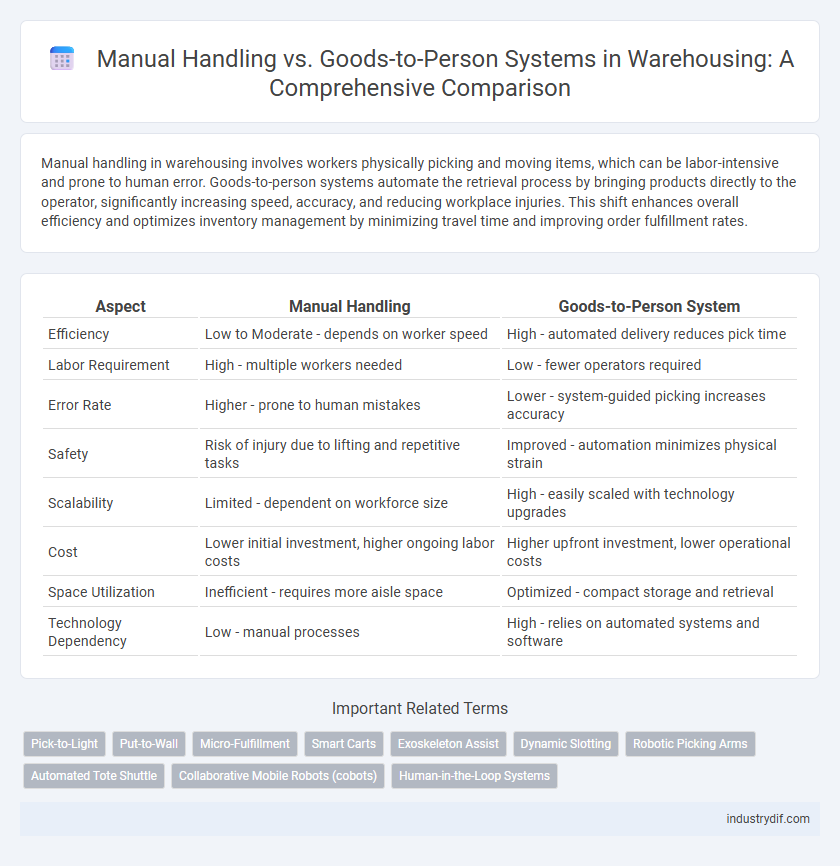

| Aspect | Manual Handling | Goods-to-Person System |

|---|---|---|

| Efficiency | Low to Moderate - depends on worker speed | High - automated delivery reduces pick time |

| Labor Requirement | High - multiple workers needed | Low - fewer operators required |

| Error Rate | Higher - prone to human mistakes | Lower - system-guided picking increases accuracy |

| Safety | Risk of injury due to lifting and repetitive tasks | Improved - automation minimizes physical strain |

| Scalability | Limited - dependent on workforce size | High - easily scaled with technology upgrades |

| Cost | Lower initial investment, higher ongoing labor costs | Higher upfront investment, lower operational costs |

| Space Utilization | Inefficient - requires more aisle space | Optimized - compact storage and retrieval |

| Technology Dependency | Low - manual processes | High - relies on automated systems and software |

Introduction to Manual Handling and Goods-to-Person Systems

Manual handling in warehousing involves the physical movement of goods by workers, which can lead to inefficiencies and injury risks. Goods-to-person systems automate the retrieval process by delivering items directly to operators, significantly enhancing speed and reducing labor strain. These systems optimize order fulfillment by integrating robotics and conveyor technologies, increasing accuracy and throughput.

Key Differences Between Manual Handling and Goods-to-Person Systems

Manual handling involves workers physically moving and picking items, which can lead to higher labor costs and increased risk of injury, whereas goods-to-person systems automate item delivery to the worker, enhancing efficiency and safety. Goods-to-person systems significantly reduce travel time and improve picking accuracy through automation and robotics, unlike manual handling that relies heavily on human labor and has slower throughput. The key differences lie in labor intensity, speed, ergonomics, and accuracy, with goods-to-person systems offering scalable solutions tailored for high-volume order fulfillment environments.

Efficiency and Productivity Comparison

Manual handling in warehousing typically results in slower order fulfillment and higher labor costs due to increased physical effort and time consumption. Goods-to-person systems significantly enhance efficiency by automating inventory retrieval and delivery directly to workers, leading to faster picking speeds and reduced fatigue. Productivity gains from goods-to-person technology often translate into higher throughput and improved accuracy compared to traditional manual processes.

Impact on Labor Costs

Manual handling in warehousing leads to higher labor costs due to increased workforce requirements and slower picking rates. Goods-to-person systems automate inventory retrieval, reducing labor demand and increasing picking efficiency. This technology-driven approach significantly lowers operational expenses by minimizing manual labor and improving throughput.

Safety and Ergonomics Considerations

Manual handling in warehousing poses significant risks of musculoskeletal injuries due to repetitive lifting, bending, and reaching, often leading to worker fatigue and long-term health issues. Goods-to-person systems enhance safety by minimizing physical strain, as automated retrieval delivers items directly to ergonomic workstations, reducing the incidence of slips, trips, and falls. Implementing these automated solutions promotes improved worker posture, decreases accident rates, and supports regulatory compliance with occupational health and safety standards.

Space Utilization and Warehouse Layout

Manual handling requires extensive aisle space and larger storage areas to accommodate worker movement and safety, often resulting in less efficient space utilization. Goods-to-person systems optimize warehouse layout by using automated retrieval technology that delivers items directly to workers, significantly reducing aisle widths and storage footprint. This advanced setup maximizes cubic space, enabling higher storage density and improved overall warehouse efficiency.

Scalability and Flexibility in Operations

Manual handling in warehousing offers limited scalability, as increasing order volumes require proportionally more labor, which can lead to bottlenecks and higher operational costs. Goods-to-person systems enhance scalability by automating the retrieval process, allowing for rapid adjustment to fluctuating demand without extensive workforce changes. Flexibility in manual handling depends heavily on worker availability and skill, whereas goods-to-person systems provide adaptable configurations that support diverse product ranges and order profiles efficiently.

Technological Requirements and Integration

Manual handling in warehousing relies on minimal technology, primarily basic equipment such as pallets, carts, and conveyors, making integration straightforward but limited in automation capabilities. Goods-to-person (G2P) systems require advanced technological infrastructure including automated storage and retrieval systems (AS/RS), robotics, and sophisticated warehouse management systems (WMS) for seamless operation and real-time inventory tracking. Integrating G2P systems demands significant IT investment and interoperability between hardware and software platforms to optimize order fulfillment efficiency and accuracy.

Return on Investment (ROI) Analysis

Manual handling systems typically incur higher labor costs and increased risk of injuries, negatively impacting ROI due to productivity losses and compensation expenses. Goods-to-person systems significantly boost throughput rates and accuracy while reducing labor requirements, leading to faster inventory turnover and lower operational costs that enhance ROI. The initial capital expenditure for automated solutions is offset by long-term savings in workforce efficiency and reduced error-related costs, resulting in a superior return on investment compared to manual handling.

Future Trends in Order Fulfillment Systems

Future trends in order fulfillment systems emphasize the integration of advanced goods-to-person (G2P) technologies to enhance efficiency and accuracy, reducing reliance on manual handling that often limits scalability. Automation, combined with AI-driven robotics and real-time inventory tracking, promises to streamline warehouse operations, minimize human error, and accelerate order processing times. The shift towards smart warehouses incorporates IoT-enabled devices and predictive analytics, driving smarter workflows and enabling seamless adaptation to fluctuating demand in e-commerce and omnichannel retail environments.

Related Important Terms

Pick-to-Light

Pick-to-Light systems significantly reduce manual handling by guiding workers with illuminated indicators to item locations, enhancing accuracy and speed in order picking. Compared to traditional manual handling, Pick-to-Light improves warehouse efficiency, minimizes errors, and reduces physical strain on employees, streamlining the goods-to-person workflow.

Put-to-Wall

Put-to-wall systems enhance warehousing efficiency by automatically guiding items to designated storage locations, reducing manual handling and errors compared to traditional manual put-away methods. This technology optimizes space utilization, accelerates order fulfillment, and improves worker ergonomics by minimizing unnecessary movement and lifting.

Micro-Fulfillment

Manual handling in warehouse micro-fulfillment centers often leads to increased labor costs and higher risk of worker injury, whereas Goods-to-Person (G2P) systems optimize space utilization and enhance picking accuracy by automating the delivery of products directly to operators. Implementing G2P solutions significantly increases throughput rates and scalability, making them ideal for e-commerce and fast-moving consumer goods environments where rapid order fulfillment is critical.

Smart Carts

Smart carts in goods-to-person systems significantly reduce manual handling by automating the retrieval and delivery of inventory, enhancing efficiency and accuracy in warehouse operations. These carts integrate advanced navigation and picking technologies, minimizing physical strain on workers and boosting overall productivity.

Exoskeleton Assist

Exoskeleton assist technology enhances manual handling efficiency by reducing worker fatigue and minimizing injury risk through biomechanical support during repetitive lifting tasks, significantly increasing productivity in warehousing environments. Goods-to-person systems integrate automated retrieval with exoskeleton aids to optimize ergonomic safety and streamline order fulfillment processes, resulting in faster throughput and improved worker well-being.

Dynamic Slotting

Dynamic slotting in Goods-to-Person (G2P) systems significantly enhances storage efficiency by automatically adjusting product positions based on demand patterns and inventory turnover. Manual handling methods lack this adaptability, often resulting in slower retrieval times and less optimized warehouse space utilization.

Robotic Picking Arms

Robotic picking arms in Goods-to-Person systems significantly reduce manual handling errors and increase throughput by automating item retrieval and order fulfillment. These advanced robotic solutions enhance warehouse efficiency by minimizing human labor, reducing physical strain, and enabling precise, high-speed picking in complex inventory environments.

Automated Tote Shuttle

Automated Tote Shuttle systems enhance warehousing efficiency by reducing manual handling labor, increasing throughput, and optimizing space utilization through mechanized shuttle movement and dynamic storage allocation. These systems streamline order fulfillment processes by automating tote retrieval and delivery, minimizing worker fatigue and error rates compared to traditional manual handling methods.

Collaborative Mobile Robots (cobots)

Collaborative mobile robots (cobots) enhance warehousing efficiency by reducing the physical strain of manual handling and enabling dynamic goods-to-person system workflows. These robots work alongside human operators to optimize order picking accuracy and speed, increasing productivity while maintaining ergonomic safety standards.

Human-in-the-Loop Systems

Human-in-the-loop systems in warehousing integrate manual handling with automated goods-to-person technologies, enhancing accuracy and efficiency by allowing human operators to oversee and intervene in complex tasks. These systems optimize workflow by combining human judgment with robotic precision, reducing errors and improving order fulfillment speed.

Manual Handling vs Goods-to-Person Systems Infographic

industrydif.com

industrydif.com