Traditional pallet racking offers a fixed storage solution that maximizes vertical space but limits flexibility and requires wide aisles for forklift access. Robotic mobile racking enhances warehouse efficiency by using automated systems to move racks, reducing aisle space and increasing storage density. This advanced technology optimizes inventory management and speeds up order fulfillment compared to conventional static shelving.

Table of Comparison

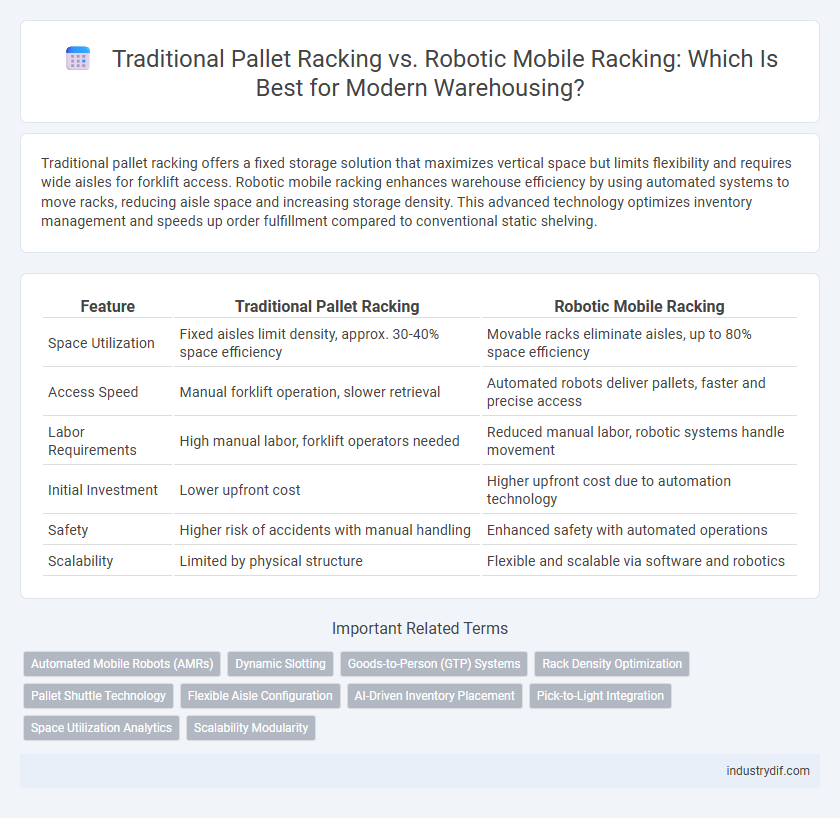

| Feature | Traditional Pallet Racking | Robotic Mobile Racking |

|---|---|---|

| Space Utilization | Fixed aisles limit density, approx. 30-40% space efficiency | Movable racks eliminate aisles, up to 80% space efficiency |

| Access Speed | Manual forklift operation, slower retrieval | Automated robots deliver pallets, faster and precise access |

| Labor Requirements | High manual labor, forklift operators needed | Reduced manual labor, robotic systems handle movement |

| Initial Investment | Lower upfront cost | Higher upfront cost due to automation technology |

| Safety | Higher risk of accidents with manual handling | Enhanced safety with automated operations |

| Scalability | Limited by physical structure | Flexible and scalable via software and robotics |

Overview of Traditional Pallet Racking Systems

Traditional pallet racking systems consist of upright frames and horizontal beams designed to store standard-sized pallets efficiently, maximizing vertical space utilization in warehouses. These systems are cost-effective, require minimal maintenance, and allow easy access with forklifts, making them a common choice for businesses with stable inventory patterns. However, they lack the flexibility and automation offered by modern solutions like robotic mobile racking, which can enhance storage density and operational efficiency.

Evolution to Robotic Mobile Racking Solutions

Traditional pallet racking requires fixed aisles and manual forklift operation, limiting storage density and operational efficiency. Robotic mobile racking systems eliminate the need for permanent aisles by using automated robots to transport racks, increasing storage capacity by up to 50% and reducing retrieval times. These advanced solutions integrate IoT and AI technologies, optimizing inventory management and enabling scalable, flexible warehouse layouts to meet growing logistics demands.

Space Utilization: Static vs. Dynamic Storage

Traditional pallet racking offers static storage with fixed aisles, leading to lower space utilization due to the need for forklift access and wide passageways. Robotic mobile racking employs dynamic storage by automatically moving racks to create temporary aisles only when needed, maximizing storage density and minimizing unused space. This dynamic system increases space utilization by up to 60% compared to conventional static systems in warehousing environments.

Installation and Maintenance Requirements

Traditional pallet racking requires manual installation involving forklifts and labor-intensive setup, with periodic inspections for structural integrity and bolt tightness to maintain safety. Robotic mobile racking systems demand professional robotic integration and software calibration, with ongoing maintenance focused on sensor accuracy, battery health, and mechanical component functionality. The automated nature of robotic systems reduces downtime and labor costs compared to the frequent manual maintenance needed for conventional racking.

Flexibility and Scalability in Modern Warehouses

Traditional pallet racking systems offer fixed storage locations that can limit flexibility and make scaling inventory capacity labor-intensive and time-consuming. Robotic mobile racking leverages autonomous robots to dynamically rearrange racks, increasing storage density and enabling seamless scalability in response to fluctuating warehouse demands. This technology enhances operational flexibility by optimizing space utilization and allowing rapid adaptation to changes in inventory volume and product variety.

Operational Efficiency and Throughput Comparison

Traditional pallet racking offers straightforward storage but often limits operational efficiency due to fixed aisle widths and manual handling, resulting in slower throughput. Robotic mobile racking maximizes space utilization by eliminating static aisles, enabling automated systems to enhance picking speed and accuracy, thereby significantly increasing throughput. This automation reduces labor costs and downtime while optimizing inventory density, leading to improved overall warehouse productivity.

Labor Costs and Workforce Implications

Traditional pallet racking requires significant manual labor for picking, stocking, and inventory management, leading to higher labor costs and increased risk of workplace injuries. Robotic mobile racking systems automate these processes, reducing the need for manual intervention and lowering overall labor expenses while improving operational efficiency. Workforce implications include a shift towards skilled labor focused on system maintenance and supervision rather than physical material handling.

Inventory Management and Real-Time Tracking

Traditional pallet racking relies on manual inventory management and periodic physical counts, which can lead to inaccuracies and delays in stock updates. Robotic mobile racking integrates automated systems with real-time tracking technology, enabling precise inventory monitoring and immediate identification of stock levels and locations. This automation significantly reduces human errors, enhances operational efficiency, and supports dynamic inventory management in modern warehousing environments.

Safety Features and Risk Reduction

Traditional pallet racking systems rely on fixed, sturdy steel structures designed to support heavy loads but pose risks such as forklift collisions and falling items, requiring stringent safety protocols like rack protection and regular inspections. Robotic mobile racking incorporates automated guided vehicles (AGVs) and sensor technology that minimize human interaction with heavy loads, significantly reducing risks of accidents, injuries, and material damage. Advanced safety features in robotic systems include collision avoidance, emergency stop mechanisms, and real-time load monitoring, resulting in enhanced workplace safety and lower operational hazards compared to traditional methods.

Return on Investment: Cost Analysis and ROI

Traditional pallet racking involves lower initial capital expenditure but incurs higher labor and space utilization costs over time, impacting overall ROI negatively. Robotic mobile racking requires a significant upfront investment in automation technology and integration but dramatically reduces labor expenses and optimizes warehouse space, leading to faster payback periods and superior long-term ROI. Cost analysis reveals robotic systems enhance inventory density and operational efficiency, delivering substantial savings that outweigh traditional systems within three to five years.

Related Important Terms

Automated Mobile Robots (AMRs)

Traditional pallet racking relies on fixed shelving systems that limit storage density and require manual labor for handling, while Robotic Mobile Racking integrated with Automated Mobile Robots (AMRs) enhances warehouse efficiency by autonomously transporting racks to picking stations, optimizing space utilization by up to 60%. AMRs equipped with AI navigation and real-time inventory management reduce operational costs and improve order accuracy, supporting scalability in dynamic warehousing environments.

Dynamic Slotting

Traditional pallet racking systems offer fixed slotting configurations that limit flexibility and result in inefficient space utilization, whereas robotic mobile racking enables dynamic slotting by automatically adjusting storage locations based on real-time inventory data, maximizing storage density and operational efficiency. Dynamic slotting in robotic mobile racking optimizes picking routes and reduces travel time, enhancing throughput and minimizing labor costs in modern warehousing environments.

Goods-to-Person (GTP) Systems

Traditional pallet racking systems rely on manual labor and forklifts to retrieve items, resulting in slower Goods-to-Person (GTP) processes and increased labor costs. Robotic mobile racking enhances GTP efficiency by autonomously transporting racks directly to workers, optimizing space utilization and accelerating order fulfillment.

Rack Density Optimization

Traditional pallet racking offers moderate rack density but often leaves unused vertical and horizontal space, limiting storage capacity within a fixed warehouse footprint. Robotic mobile racking maximizes rack density by eliminating the need for multiple aisles, enabling dynamic movement of racks and increasing storage volume per square meter by up to 60%.

Pallet Shuttle Technology

Traditional pallet racking systems rely on manual forklifts and fixed storage lanes, limiting storage density and retrieval speed, while Robotic Mobile Racking with Pallet Shuttle Technology significantly enhances space utilization by automating pallet movement on mobile shuttles within aisle lanes. Pallet Shuttle Technology increases operational efficiency through precise, high-density storage and faster load/unload cycles, reducing labor costs and maximizing warehouse throughput.

Flexible Aisle Configuration

Traditional pallet racking systems require fixed aisle configurations, limiting warehouse layout flexibility and reducing storage density. Robotic mobile racking enables dynamic aisle creation, optimizing space utilization by only opening aisles when needed and significantly increasing storage capacity and operational efficiency.

AI-Driven Inventory Placement

AI-driven inventory placement in robotic mobile racking systems optimizes storage density by dynamically analyzing real-time data to position pallets for faster retrieval and space maximization, surpassing the static configuration of traditional pallet racking. This technology reduces labor costs and minimizes human error, significantly enhancing operational efficiency and inventory accuracy in modern warehousing environments.

Pick-to-Light Integration

Traditional pallet racking systems rely on manual labor and fixed aisle access, limiting efficiency and accuracy in order picking, while robotic mobile racking integrates Pick-to-Light technology to guide operators with real-time visual cues, enhancing speed and reducing errors. This advanced integration optimizes warehouse space by dynamically adjusting racking configurations and streamlines picking processes through automated light-directed instructions, significantly improving productivity and inventory management.

Space Utilization Analytics

Traditional pallet racking systems often result in inefficient space utilization due to fixed aisle widths and static storage layouts, limiting storage density and accessibility. In contrast, robotic mobile racking leverages space utilization analytics to dynamically adjust aisle configurations, maximizing storage capacity by up to 50% and optimizing warehouse footprint for increased operational efficiency.

Scalability Modularity

Traditional pallet racking offers fixed scalability through modular steel frames that can be manually reconfigured to expand storage capacity, but often requires significant labor and downtime. Robotic mobile racking enhances scalability with autonomous systems that dynamically adjust configurations on-demand, optimizing space utilization and enabling seamless, real-time modular expansion without interrupting warehouse operations.

Traditional pallet racking vs Robotic mobile racking Infographic

industrydif.com

industrydif.com