Order fulfillment centers prioritize accuracy and efficiency in processing, packing, and shipping customer orders, often serving a wide geographic area with standardized inventory management systems. Hyperlocal distribution emphasizes rapid delivery within a confined geographic region, leveraging strategically placed warehouses or dark stores to minimize transit times and meet immediate customer demands. The two approaches differ in scale and speed, where order fulfillment targets broad reach and inventory depth, while hyperlocal distribution focuses on proximity and expedited service.

Table of Comparison

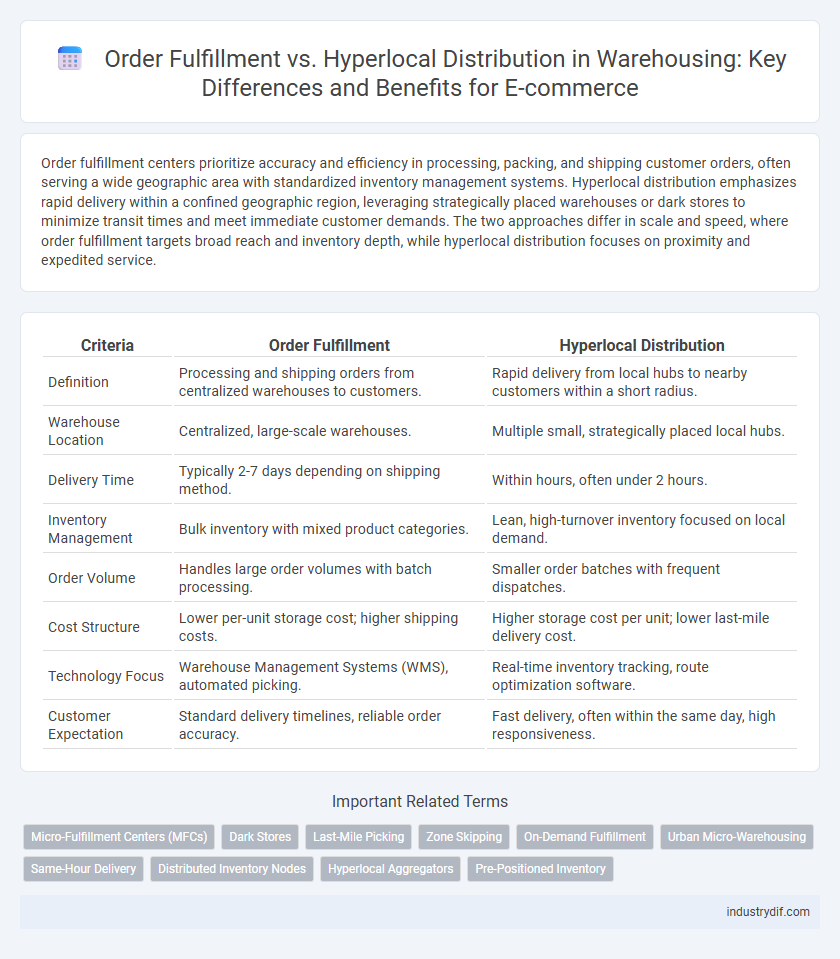

| Criteria | Order Fulfillment | Hyperlocal Distribution |

|---|---|---|

| Definition | Processing and shipping orders from centralized warehouses to customers. | Rapid delivery from local hubs to nearby customers within a short radius. |

| Warehouse Location | Centralized, large-scale warehouses. | Multiple small, strategically placed local hubs. |

| Delivery Time | Typically 2-7 days depending on shipping method. | Within hours, often under 2 hours. |

| Inventory Management | Bulk inventory with mixed product categories. | Lean, high-turnover inventory focused on local demand. |

| Order Volume | Handles large order volumes with batch processing. | Smaller order batches with frequent dispatches. |

| Cost Structure | Lower per-unit storage cost; higher shipping costs. | Higher storage cost per unit; lower last-mile delivery cost. |

| Technology Focus | Warehouse Management Systems (WMS), automated picking. | Real-time inventory tracking, route optimization software. |

| Customer Expectation | Standard delivery timelines, reliable order accuracy. | Fast delivery, often within the same day, high responsiveness. |

Introduction to Order Fulfillment and Hyperlocal Distribution

Order fulfillment involves processes such as picking, packing, and shipping products from centralized warehouses to customers, ensuring accurate and timely delivery. Hyperlocal distribution focuses on delivering goods within a close geographic proximity, often leveraging local inventory and rapid delivery methods to meet immediate customer demand. Both strategies optimize supply chain efficiency but differ in scale, speed, and delivery scope to address specific market needs.

Core Concepts: Defining Order Fulfillment

Order fulfillment refers to the complete process of receiving, processing, and delivering customer orders within warehousing operations. It involves inventory management, picking, packing, and shipping to ensure timely and accurate delivery. Unlike hyperlocal distribution, which emphasizes rapid delivery within a confined geographic area, order fulfillment focuses on the end-to-end supply chain efficiency and customer satisfaction.

What is Hyperlocal Distribution?

Hyperlocal distribution refers to the process of delivering products within a very limited geographic area, typically focusing on the last-mile delivery from local warehouses or stores directly to customers. It leverages proximity to reduce delivery times and enhance customer satisfaction by enabling same-day or even within-the-hour order fulfillment. This approach contrasts with traditional order fulfillment models that often rely on centralized warehouses and longer delivery windows.

Key Differences Between Order Fulfillment and Hyperlocal Distribution

Order fulfillment centers manage large volumes of inventory to process and ship customer orders nationwide, prioritizing accuracy and speed in handling diverse product ranges. Hyperlocal distribution focuses on rapid delivery within a limited geographic area, leveraging nearby warehouses or stores to reduce transit times and meet immediate consumer demand. While order fulfillment emphasizes centralized efficiency and scale, hyperlocal distribution prioritizes proximity and real-time inventory management to support same-day or instant delivery services.

Warehousing Infrastructure: Centralized vs Decentralized Models

Centralized warehousing infrastructure consolidates inventory in a single or few large facilities, optimizing storage costs and streamlined order fulfillment for bulk shipments. Decentralized warehousing supports hyperlocal distribution by positioning multiple smaller warehouses closer to end customers, significantly reducing delivery times and enhancing last-mile efficiency. The trade-off between these models hinges on balancing operational costs against speed and customer experience in supply chain logistics.

Impact on Delivery Speed and Customer Expectations

Order fulfillment centers typically prioritize large-scale inventory management and centralized processing, resulting in longer delivery windows but increased order accuracy. Hyperlocal distribution hubs minimize delivery distances by using neighborhood-based stock points, dramatically accelerating delivery speed to meet rising customer expectations for same-day or instant delivery. Consumer demand for faster shipments has driven the growth of hyperlocal logistics, challenging traditional warehousing models to adopt more agile and responsive fulfillment strategies.

Inventory Management in Both Approaches

Order fulfillment leverages centralized inventory management systems to optimize stock levels, streamline picking, packing, and shipping processes, ensuring accuracy and speed for e-commerce orders. Hyperlocal distribution emphasizes decentralized inventory stored in multiple micro-warehouses near customer locations, enabling rapid delivery through real-time inventory tracking and dynamic replenishment strategies. Both approaches require robust inventory visibility technologies like RFID and AI-driven analytics to reduce stockouts, minimize holding costs, and improve overall supply chain efficiency.

Cost Implications: Comparing Operational Expenses

Order fulfillment centers typically incur higher fixed costs due to large-scale warehousing, inventory management, and centralized logistics, while hyperlocal distribution models emphasize variable costs driven by last-mile delivery and multiple small inventory points. Operational expenses in order fulfillment include warehousing rent, labor for picking and packing, and bulk transportation, contrasting with hyperlocal distribution's investment in localized storage, rapid delivery fleets, and technology for real-time demand tracking. Evaluating cost implications requires analyzing trade-offs between economies of scale in order fulfillment and the premium on speed and proximity inherent in hyperlocal distribution systems.

Technology Integration and Automation Trends

Order fulfillment and hyperlocal distribution increasingly leverage advanced technology integration and automation to optimize operations, reduce delivery times, and enhance accuracy. Automated warehouse management systems (WMS), robotics, and real-time data analytics streamline inventory handling in order fulfillment, while hyperlocal distribution relies on AI-driven route optimization and IoT-enabled tracking for last-mile delivery efficiency. Emerging trends include robotic process automation (RPA), autonomous delivery vehicles, and cloud-based platforms that enable seamless synchronization between inventory availability and hyperlocal demand fluctuations.

Choosing the Right Model for Your Business

Order fulfillment centers streamline inventory management and expedite shipping by consolidating products in centralized warehouses, ideal for businesses targeting wide geographic areas and bulk shipments. Hyperlocal distribution focuses on proximity to end customers, enabling faster delivery and reduced last-mile costs, making it suitable for businesses prioritizing immediate delivery in densely populated regions. Selecting the right model depends on factors like target market radius, delivery speed requirements, and operational scalability aligned with customer expectations.

Related Important Terms

Micro-Fulfillment Centers (MFCs)

Micro-Fulfillment Centers (MFCs) revolutionize order fulfillment by enabling rapid, scalable storage and picking within urban areas, significantly reducing delivery times compared to traditional warehousing. Unlike hyperlocal distribution networks that rely on multiple small vendors, MFCs centralize inventory in compact, automated spaces to optimize efficiency and meet growing e-commerce demand.

Dark Stores

Dark stores serve as specialized fulfillment centers optimized for hyperlocal distribution, enabling rapid order processing and last-mile delivery within tightly defined urban areas. Unlike traditional warehousing focused on bulk storage and large-scale order fulfillment, dark stores prioritize inventory accuracy and proximity to consumers to minimize delivery times and enhance customer satisfaction.

Last-Mile Picking

Last-mile picking in order fulfillment emphasizes accuracy and speed to ensure timely delivery, often relying on centralized warehouses with structured inventory management. Hyperlocal distribution prioritizes proximity and flexibility by utilizing multiple micro-fulfillment centers, reducing transit time and enhancing the efficiency of last-mile logistics.

Zone Skipping

Zone skipping streamlines order fulfillment by consolidating shipments into fewer transit zones, reducing handling and delivery times compared to traditional hyperlocal distribution models. This approach minimizes transportation costs and accelerates last-mile delivery, enhancing overall supply chain efficiency.

On-Demand Fulfillment

On-demand fulfillment in warehousing emphasizes rapid order processing and delivery within localized areas, contrasting with traditional hyperlocal distribution that relies on decentralized inventory hubs to reduce transit times. This approach enhances customer satisfaction by enabling same-day or faster deliveries through real-time inventory updates and dynamic route optimization.

Urban Micro-Warehousing

Urban micro-warehousing enhances order fulfillment by strategically positioning inventory closer to end consumers, reducing delivery times and last-mile costs. This hyperlocal distribution method supports high-density city environments by enabling rapid, flexible, and cost-efficient handling of e-commerce orders.

Same-Hour Delivery

Same-hour delivery in warehousing hinges on hyperlocal distribution, leveraging strategically located micro-fulfillment centers to expedite order picking and shipping within tight timeframes. Traditional order fulfillment centers, while efficient for bulk processing, often lack the proximity and agility required to achieve rapid dispatch for hyperlocal, same-hour deliveries.

Distributed Inventory Nodes

Order fulfillment with distributed inventory nodes enhances supply chain efficiency by decentralizing stock storage across multiple warehouses, reducing delivery times and shipping costs. Hyperlocal distribution leverages these nodes to enable rapid, last-mile delivery within specific geographic areas, optimizing inventory allocation and meeting consumer demand with greater precision.

Hyperlocal Aggregators

Hyperlocal aggregators leverage advanced warehousing strategies to ensure rapid order fulfillment within localized areas, minimizing delivery times and enhancing customer satisfaction. By consolidating inventory from multiple suppliers in strategically placed micro-fulfillment centers, these aggregators optimize resource allocation and streamline last-mile logistics for hyperlocal distribution.

Pre-Positioned Inventory

Pre-positioned inventory in warehousing enhances order fulfillment by strategically locating stock closer to high-demand areas, reducing delivery times and improving customer satisfaction. Hyperlocal distribution leverages these inventory hubs to enable rapid, cost-effective last-mile delivery within localized regions, optimizing supply chain efficiency.

Order Fulfillment vs Hyperlocal Distribution Infographic

industrydif.com

industrydif.com