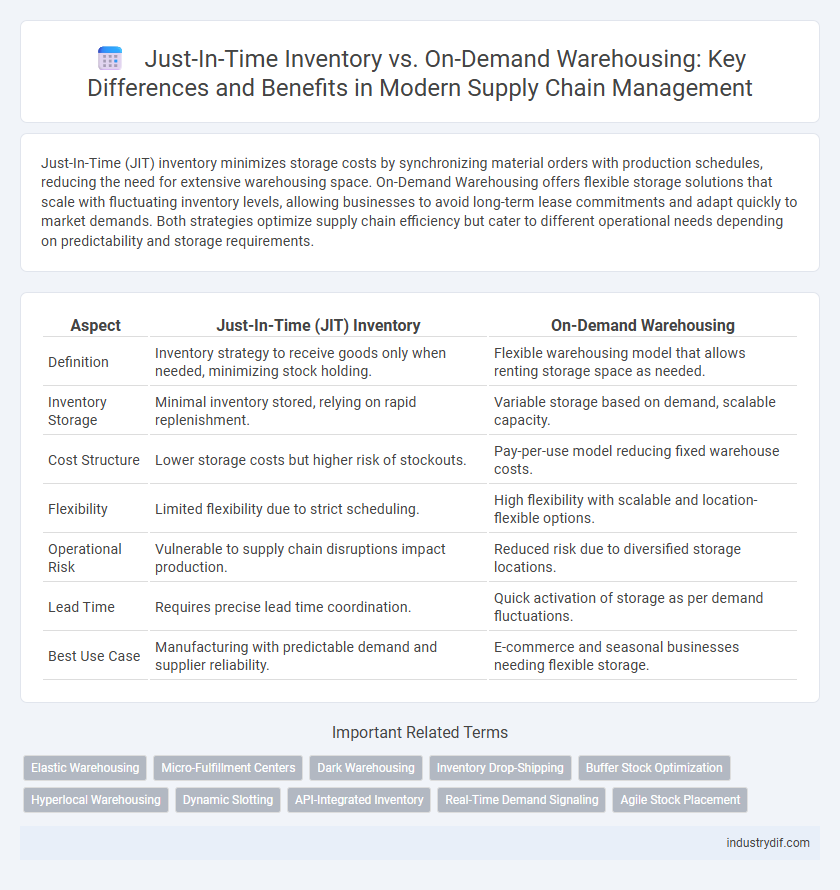

Just-In-Time (JIT) inventory minimizes storage costs by synchronizing material orders with production schedules, reducing the need for extensive warehousing space. On-Demand Warehousing offers flexible storage solutions that scale with fluctuating inventory levels, allowing businesses to avoid long-term lease commitments and adapt quickly to market demands. Both strategies optimize supply chain efficiency but cater to different operational needs depending on predictability and storage requirements.

Table of Comparison

| Aspect | Just-In-Time (JIT) Inventory | On-Demand Warehousing |

|---|---|---|

| Definition | Inventory strategy to receive goods only when needed, minimizing stock holding. | Flexible warehousing model that allows renting storage space as needed. |

| Inventory Storage | Minimal inventory stored, relying on rapid replenishment. | Variable storage based on demand, scalable capacity. |

| Cost Structure | Lower storage costs but higher risk of stockouts. | Pay-per-use model reducing fixed warehouse costs. |

| Flexibility | Limited flexibility due to strict scheduling. | High flexibility with scalable and location-flexible options. |

| Operational Risk | Vulnerable to supply chain disruptions impact production. | Reduced risk due to diversified storage locations. |

| Lead Time | Requires precise lead time coordination. | Quick activation of storage as per demand fluctuations. |

| Best Use Case | Manufacturing with predictable demand and supplier reliability. | E-commerce and seasonal businesses needing flexible storage. |

Understanding Just-In-Time (JIT) Inventory Management

Just-In-Time (JIT) inventory management minimizes warehouse storage by synchronizing stock arrival precisely with production or demand schedules, reducing holding costs and waste. This strategy relies on real-time data analytics and strong supplier relationships to ensure seamless inventory flow and avoid delays. JIT contrasts with on-demand warehousing by emphasizing minimal stock levels rather than flexible storage capacity.

Defining On-Demand Warehousing Solutions

On-demand warehousing solutions offer flexible storage options by allowing businesses to rent space as needed, reducing fixed costs and improving scalability. Unlike Just-In-Time inventory, which relies on precise timing to minimize stock levels, on-demand warehousing provides immediate access to warehouse capacity in response to fluctuating demand. This approach enhances supply chain agility by optimizing inventory distribution and mitigating risks of overstock or stockouts.

Key Differences Between JIT and On-Demand Warehousing

Just-In-Time (JIT) inventory relies on precisely timed deliveries to reduce warehouse storage needs, minimizing carrying costs and emphasizing supplier reliability. On-demand warehousing offers flexible, scalable storage solutions by renting space only when needed, supporting fluctuating inventory levels without long-term commitments. The key difference lies in JIT's focus on inventory flow efficiency versus on-demand warehousing's adaptability to variable storage demands.

Benefits of Just-In-Time Inventory for Businesses

Just-In-Time (JIT) inventory reduces warehousing costs by minimizing inventory levels and lowering storage expenses, enhancing cash flow management for businesses. It improves operational efficiency by synchronizing production schedules with demand, reducing waste and excess stock. This approach also increases responsiveness to market changes and customer needs, fostering streamlined supply chain operations.

Advantages of Adopting On-Demand Warehousing

On-demand warehousing offers significant cost savings by eliminating the need for long-term lease commitments, allowing businesses to scale storage space flexibly in response to fluctuating inventory levels. This model enhances supply chain agility through rapid access to strategically located warehouses, reducing transit times and improving delivery speed. Real-time inventory visibility and data-driven management optimize stock control, minimizing excess inventory and enhancing overall operational efficiency.

Challenges of Implementing JIT Inventory Systems

Implementing Just-In-Time (JIT) inventory systems in warehousing faces challenges such as the risk of supply chain disruptions due to minimal buffer stock, requiring precise coordination with suppliers and logistics partners. Demand forecasting inaccuracies can lead to stockouts or delays, negatively impacting customer satisfaction and operational efficiency. Integrating advanced inventory management software and maintaining consistent communication across the supply chain are critical to overcoming these hurdles in JIT implementation.

Potential Drawbacks of On-Demand Warehousing

On-demand warehousing offers flexibility but can result in higher costs due to variable pricing models and potential lack of long-term contracts. It may lead to inconsistent storage quality and limited control over inventory security compared to traditional warehouses. Reliance on third-party providers increases the risk of supply chain disruptions and less predictable fulfillment times.

Case Studies: JIT vs. On-Demand in Practice

Case studies comparing Just-In-Time (JIT) inventory with On-Demand Warehousing reveal distinct operational impacts, with JIT systems emphasizing minimal stock levels and synchronized supplier deliveries, as demonstrated by Toyota's streamlined production reducing inventory costs by up to 30%. On-Demand Warehousing, utilized by companies like Amazon during peak seasons, offers scalable storage solutions that improve flexibility and reduce warehousing costs by leveraging third-party facilities only when needed. These case studies highlight that JIT excels in predictable supply chains, while On-Demand Warehousing provides agility for fluctuating demand environments.

Choosing the Right Model for Your Supply Chain

Just-In-Time (JIT) inventory minimizes storage costs by synchronizing material orders precisely with production schedules, ideal for predictable demand and stable supply chains. On-Demand Warehousing offers scalable, flexible storage solutions that adapt to fluctuating inventory volumes and seasonal spikes, reducing long-term lease commitments. Selecting the right model depends on demand variability, inventory turnover rates, and supply chain agility to optimize cost efficiency and operational responsiveness.

Future Trends in Inventory and Warehousing Strategies

Just-In-Time inventory increasingly integrates with on-demand warehousing solutions, driving a shift toward more flexible, tech-enabled supply chains that reduce storage costs and improve responsiveness. Advanced data analytics and AI optimize inventory levels, predicting demand patterns with greater accuracy to enable seamless coordination between manufacturers and warehousing providers. Future trends emphasize hyper-localized warehousing networks and real-time inventory visibility, supporting rapid delivery and minimizing waste in global logistics operations.

Related Important Terms

Elastic Warehousing

Elastic warehousing offers a scalable, cost-efficient solution by aligning storage capacity directly with fluctuating demand, minimizing holding costs compared to traditional Just-In-Time Inventory methods. This approach enhances supply chain agility and responsiveness by leveraging on-demand warehousing spaces to accommodate variable stock levels without long-term commitments.

Micro-Fulfillment Centers

Micro-fulfillment centers optimize Just-In-Time (JIT) inventory by enabling rapid stock replenishment and minimizing holding costs through automated, localized storage solutions. On-demand warehousing complements micro-fulfillment by providing flexible, scalable space for peak inventory periods, enhancing supply chain responsiveness.

Dark Warehousing

Dark warehousing, a form of on-demand warehousing, minimizes inventory holding costs by operating fully automated, unmanned facilities that enable just-in-time inventory replenishment and rapid order fulfillment. Unlike traditional just-in-time strategies relying on close supplier coordination, dark warehouses leverage real-time data analytics and robotics to optimize space utilization and reduce lead times in the supply chain.

Inventory Drop-Shipping

Just-In-Time (JIT) inventory minimizes warehousing needs by synchronizing supply arrivals with production schedules, while on-demand warehousing offers flexible, scalable storage solutions activated only when needed. Inventory drop-shipping integrates seamlessly with on-demand warehousing, enabling direct order fulfillment from suppliers to customers, reducing inventory holding costs and optimizing delivery speed.

Buffer Stock Optimization

Just-In-Time (JIT) inventory minimizes buffer stock by synchronizing deliveries precisely with production schedules, reducing holding costs and warehouse space requirements. On-demand warehousing optimizes buffer stock by leveraging flexible, scalable storage solutions that adjust quickly to fluctuating demand, ensuring inventory availability without overstocking.

Hyperlocal Warehousing

Hyperlocal warehousing enhances Just-In-Time inventory by positioning products closer to end consumers, reducing lead times and transportation costs while supporting rapid fulfillment. On-demand warehousing leverages flexible, scalable storage solutions in hyperlocal areas, enabling businesses to dynamically adjust inventory levels based on real-time demand fluctuations and market trends.

Dynamic Slotting

Dynamic slotting in Just-In-Time (JIT) inventory systems optimizes space utilization by continuously adjusting warehouse layouts based on real-time demand and product velocity, reducing handling time and improving efficiency. In on-demand warehousing, dynamic slotting enhances flexibility by enabling rapid reconfiguration of storage locations to accommodate fluctuating inventory levels and diverse product types, minimizing operational costs and maximizing throughput.

API-Integrated Inventory

API-integrated inventory systems in Just-In-Time (JIT) inventory enable real-time stock level synchronization, minimizing overstock and reducing holding costs by coordinating precise supplier deliveries. On-demand warehousing leverages API connectivity to dynamically allocate storage space, offering scalable inventory management that responds instantly to fluctuating demand without long-term commitments.

Real-Time Demand Signaling

Real-time demand signaling enhances Just-In-Time inventory systems by enabling precise synchronization between supply and immediate customer needs, minimizing excess stock and storage costs. On-demand warehousing leverages this signaling to dynamically allocate space based on current demand patterns, improving flexibility and operational efficiency across the supply chain.

Agile Stock Placement

Agile stock placement in just-in-time inventory minimizes storage costs and reduces stockouts by synchronizing replenishment with production schedules, ensuring materials arrive precisely when needed. On-demand warehousing enhances this agility by enabling flexible, scalable storage solutions that adapt instantly to fluctuating inventory demands and market conditions.

Just-In-Time Inventory vs On-Demand Warehousing Infographic

industrydif.com

industrydif.com