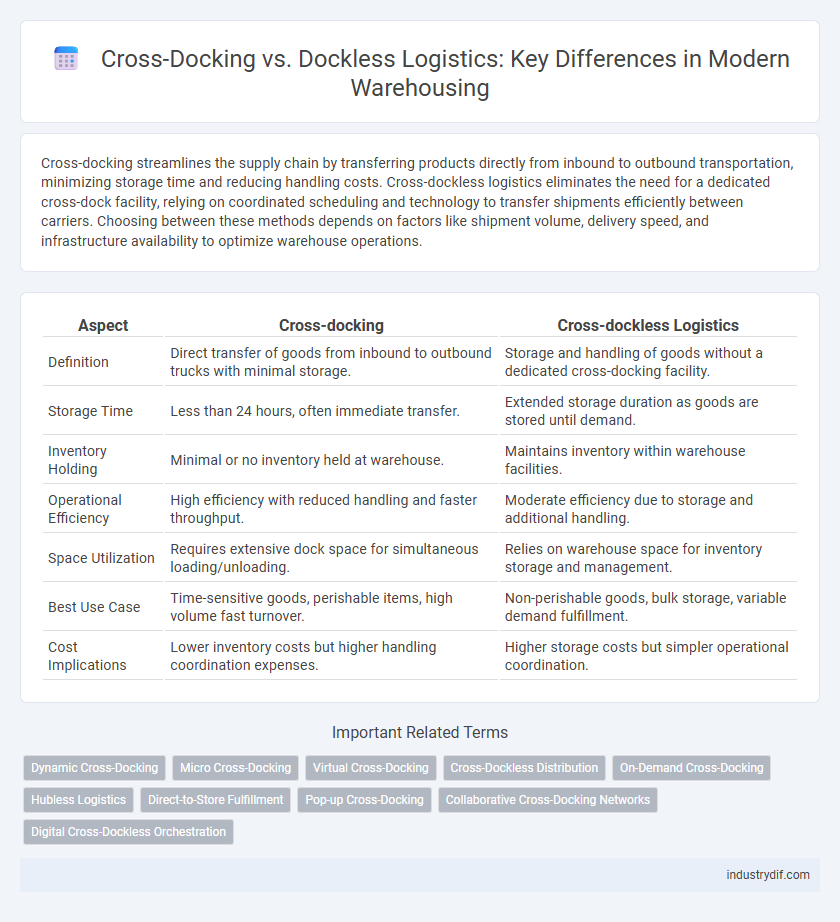

Cross-docking streamlines the supply chain by transferring products directly from inbound to outbound transportation, minimizing storage time and reducing handling costs. Cross-dockless logistics eliminates the need for a dedicated cross-dock facility, relying on coordinated scheduling and technology to transfer shipments efficiently between carriers. Choosing between these methods depends on factors like shipment volume, delivery speed, and infrastructure availability to optimize warehouse operations.

Table of Comparison

| Aspect | Cross-docking | Cross-dockless Logistics |

|---|---|---|

| Definition | Direct transfer of goods from inbound to outbound trucks with minimal storage. | Storage and handling of goods without a dedicated cross-docking facility. |

| Storage Time | Less than 24 hours, often immediate transfer. | Extended storage duration as goods are stored until demand. |

| Inventory Holding | Minimal or no inventory held at warehouse. | Maintains inventory within warehouse facilities. |

| Operational Efficiency | High efficiency with reduced handling and faster throughput. | Moderate efficiency due to storage and additional handling. |

| Space Utilization | Requires extensive dock space for simultaneous loading/unloading. | Relies on warehouse space for inventory storage and management. |

| Best Use Case | Time-sensitive goods, perishable items, high volume fast turnover. | Non-perishable goods, bulk storage, variable demand fulfillment. |

| Cost Implications | Lower inventory costs but higher handling coordination expenses. | Higher storage costs but simpler operational coordination. |

Introduction to Cross-docking and Cross-dockless Logistics

Cross-docking is a logistics strategy where incoming goods are directly transferred from inbound to outbound transportation with minimal or no storage time, optimizing supply chain efficiency and reducing inventory costs. Cross-dockless logistics eliminates the traditional cross-dock facility, leveraging direct shipments from suppliers to customers or retail locations, enhancing speed and reducing handling requirements. Both methods streamline distribution processes but differ in infrastructure reliance and operational flow.

Defining Cross-docking in Modern Warehousing

Cross-docking in modern warehousing is a logistics strategy where incoming shipments are directly transferred to outbound transportation with minimal or no storage time, optimizing inventory flow and reducing handling costs. This method enhances supply chain efficiency by minimizing warehousing needs and accelerating delivery times. In contrast, cross-dockless logistics eliminates the traditional cross-docking process, often relying on centralized storage and inventory holding to manage distribution.

What is Cross-dockless Logistics?

Cross-dockless logistics refers to a warehousing strategy where goods bypass traditional cross-docking facilities and are instead directly transferred from suppliers to customers or retail locations without intermediate storage. This approach minimizes handling and storage costs while accelerating delivery times by eliminating the need for sorting hubs. Implementing cross-dockless logistics relies heavily on advanced transportation management systems (TMS) and real-time tracking to coordinate shipments efficiently.

Key Differences Between Cross-docking and Cross-dockless Methods

Cross-docking involves the direct transfer of goods from inbound to outbound transportation with minimal or no storage time, optimizing inventory flow and reducing handling costs. Cross-dockless logistics eliminates the centralized sorting facility by using decentralized hubs or direct ship-from-supplier models, prioritizing speed and reducing bottlenecks. Key differences include the presence of a physical cross-dock in traditional methods versus a more flexible, hub-based or direct distribution approach in cross-dockless systems.

Operational Workflow Comparison

Cross-docking logistics streamlines the operational workflow by immediately transferring goods from inbound to outbound transportation, minimizing storage time and reducing handling costs. Cross-dockless logistics eliminates the need for centralized docking facilities by leveraging direct shipping from suppliers to customers or retail points, which accelerates delivery but requires advanced coordination and real-time inventory tracking. Comparing these workflows reveals that cross-docking optimizes throughput in distribution centers, while cross-dockless models emphasize agility and reduce reliance on physical warehousing infrastructure.

Advantages of Cross-docking in Supply Chains

Cross-docking streamlines supply chains by minimizing storage needs and reducing inventory holding costs, enabling faster product turnover and delivery. This method enhances operational efficiency through direct transfer of goods from inbound to outbound transportation, cutting down lead times and improving order accuracy. By optimizing warehouse space and labor utilization, cross-docking supports just-in-time inventory strategies, benefiting retailers and manufacturers with increased responsiveness and reduced supply chain complexity.

Benefits of Cross-dockless Logistics Solutions

Cross-dockless logistics solutions streamline inventory management by eliminating the need for physical cross-docking facilities, reducing handling costs and transit times. This approach enhances supply chain flexibility, allowing direct shipments from suppliers to end customers without intermediate stops, improving delivery speed and accuracy. Companies benefit from lower capital expenditure and increased scalability in warehousing operations through cross-dockless methodologies.

Challenges and Limitations of Each Approach

Cross-docking streamlines inventory flow by directly transferring goods from inbound to outbound transportation, yet it faces challenges such as dependency on precise timing and coordination, and limited flexibility in handling unexpected delays or product mix changes. Cross-dockless logistics, while offering greater flexibility and cost savings by eliminating centralized transfer points, encounters limitations including increased complexity in route planning, potential for inventory mismanagement, and higher risk of delivery errors. Both approaches require robust technology integration and real-time data management to mitigate these operational challenges and optimize supply chain efficiency.

Industry Use Cases: When to Choose Cross-docking vs Cross-dockless

Cross-docking is ideal for perishable goods, retail replenishment, and time-sensitive shipments where speed and minimal storage reduce handling costs and inventory holding. Cross-dockless logistics suits industries with variable demand patterns or bulk materials requiring flexible sorting and staging, such as manufacturing and e-commerce distribution centers. Selecting between cross-docking and cross-dockless depends on product type, delivery urgency, and warehouse layout to optimize supply chain efficiency.

Future Trends in Warehousing: Integration and Innovation

Future trends in warehousing emphasize the integration of automated cross-docking systems with advanced AI-driven inventory management, reducing handling times and increasing throughput efficiency. Cross-dockless logistics leverage real-time data analytics and IoT connectivity to optimize direct shipments while minimizing warehousing costs and storage needs. Innovations in robotics and cloud-based platforms further enable seamless coordination between suppliers and distribution centers, enhancing supply chain resilience and scalability.

Related Important Terms

Dynamic Cross-Docking

Dynamic cross-docking optimizes inventory flow by quickly transferring goods from inbound to outbound transportation without storage, reducing handling time and storage costs. Unlike traditional cross-dockless logistics, dynamic cross-docking adapts in real-time to demand fluctuations, enhancing supply chain efficiency and minimizing delays.

Micro Cross-Docking

Micro cross-docking streamlines warehousing by transferring goods directly from inbound to outbound transportation with minimal storage, enhancing inventory turnover and reducing handling costs. Unlike traditional cross-docking, cross-dockless logistics eliminates storage space requirements entirely, relying on precise timing and synchronized supply chain operations to optimize delivery speed and efficiency.

Virtual Cross-Docking

Virtual Cross-Docking optimizes warehousing by eliminating the need for physical dock space, allowing products to be electronically sorted and routed directly from inbound to outbound transportation. This method reduces storage costs, accelerates delivery times, and enhances supply chain efficiency compared to traditional cross-docking facilities.

Cross-Dockless Distribution

Cross-dockless distribution eliminates the need for traditional cross-docking facilities by directly transferring goods from inbound to outbound transportation, reducing handling time and storage costs. This method enhances supply chain efficiency by minimizing inventory holding and speeding up delivery in just-in-time warehousing models.

On-Demand Cross-Docking

On-demand cross-docking streamlines warehousing by directly transferring incoming goods to outbound transportation without storage, reducing handling times and inventory costs compared to traditional cross-dockless logistics where goods may be stored before shipment. This method enhances supply chain efficiency by enabling faster order fulfillment and minimizing warehouse space utilization.

Hubless Logistics

Cross-dockless logistics eliminates the need for centralized hubs by directly transferring goods from inbound to outbound transportation, reducing handling times and storage costs. This hubless approach enhances supply chain efficiency by minimizing delays and allowing faster delivery compared to traditional cross-docking methods.

Direct-to-Store Fulfillment

Cross-docking enhances Direct-to-Store Fulfillment by minimizing storage time and expediting product flow from suppliers to retail locations, improving inventory turnover and reducing handling costs. In contrast, cross-dockless logistics relies on traditional warehousing and storage, leading to longer lead times and higher holding expenses, which can delay replenishment and impact shelf availability.

Pop-up Cross-Docking

Pop-up cross-docking enhances warehousing efficiency by temporarily establishing cross-docking operations at strategic locations, reducing storage time and streamlining inventory flow. Unlike traditional or cross-dockless logistics, pop-up models optimize supply chain responsiveness during peak demand or special events, minimizing handling costs and transit delays.

Collaborative Cross-Docking Networks

Collaborative cross-docking networks optimize supply chain efficiency by synchronizing multiple stakeholders to streamline inventory flow without long-term storage, contrasting with cross-dockless logistics that bypass centralized transfer points. These networks reduce handling times and transportation costs while enhancing real-time data sharing across distribution channels for improved order fulfillment.

Digital Cross-Dockless Orchestration

Digital cross-dockless orchestration enhances warehousing efficiency by eliminating the need for traditional docking stations and enabling real-time coordination of inventory movement through advanced software platforms. This approach reduces handling times, optimizes space utilization, and integrates seamlessly with supply chain management systems to streamline logistics operations.

Cross-docking vs Cross-dockless Logistics Infographic

industrydif.com

industrydif.com