Pick and Pack is a traditional warehousing method where workers manually select items from shelving units and prepare them for shipment, emphasizing flexibility for varied order profiles. Goods-to-Person automation optimizes efficiency by bringing inventory directly to the worker, reducing travel time and increasing throughput in high-volume environments. This technology-driven approach significantly enhances picking speed and accuracy compared to manual Pick and Pack processes.

Table of Comparison

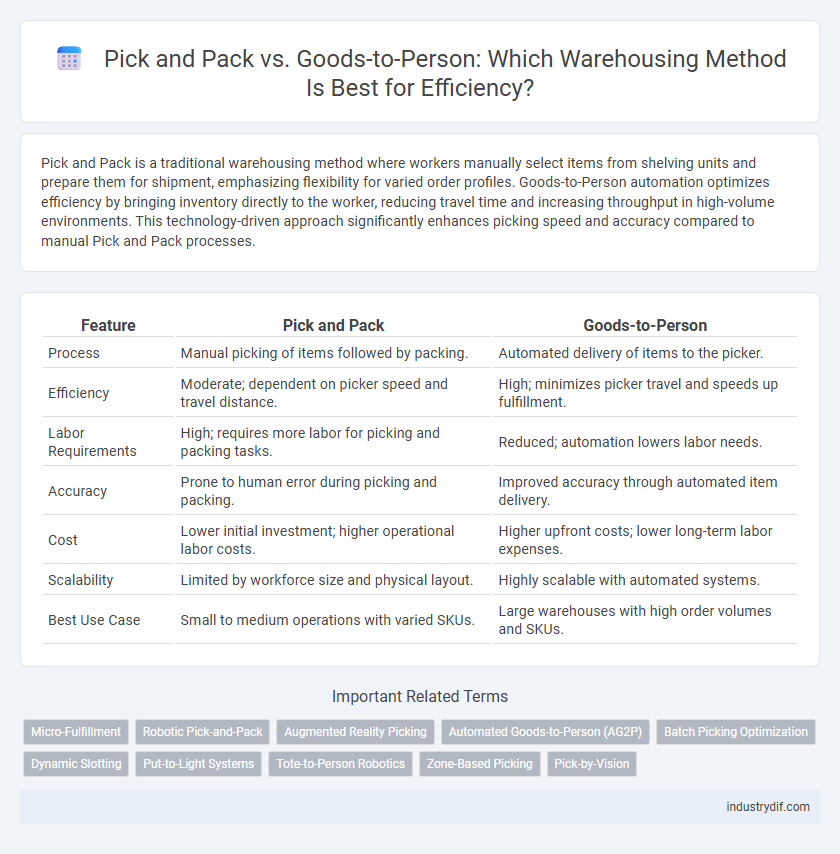

| Feature | Pick and Pack | Goods-to-Person |

|---|---|---|

| Process | Manual picking of items followed by packing. | Automated delivery of items to the picker. |

| Efficiency | Moderate; dependent on picker speed and travel distance. | High; minimizes picker travel and speeds up fulfillment. |

| Labor Requirements | High; requires more labor for picking and packing tasks. | Reduced; automation lowers labor needs. |

| Accuracy | Prone to human error during picking and packing. | Improved accuracy through automated item delivery. |

| Cost | Lower initial investment; higher operational labor costs. | Higher upfront costs; lower long-term labor expenses. |

| Scalability | Limited by workforce size and physical layout. | Highly scalable with automated systems. |

| Best Use Case | Small to medium operations with varied SKUs. | Large warehouses with high order volumes and SKUs. |

Introduction to Pick and Pack vs Goods-to-Person

Pick and Pack systems involve workers manually selecting items from storage and packing them for shipment, relying heavily on human labor and traditional shelving. Goods-to-Person technology automates item retrieval by bringing products directly to the worker, significantly increasing efficiency and reducing errors. This shift enhances order accuracy and speeds up fulfillment processes in modern warehouses.

Defining Pick and Pack in Modern Warehousing

Pick and Pack in modern warehousing involves manually selecting items from inventory and packaging them for shipment, emphasizing accuracy and speed in order fulfillment. This traditional method relies on warehouse workers navigating aisles to collect products based on customer orders, often supported by barcode scanning and inventory management systems. Its efficiency is critical for handling diverse SKUs and fluctuating order volumes in e-commerce and retail distribution centers.

Understanding Goods-to-Person Systems

Goods-to-Person systems streamline warehouse operations by bringing items directly to workers, significantly reducing travel time and increasing picking accuracy compared to traditional Pick and Pack methods. These automated solutions leverage robotics and conveyor technology to enhance order fulfillment speed and optimize space utilization. Implementing Goods-to-Person technology results in higher throughput and improved worker ergonomics, making it ideal for high-volume, fast-paced distribution centers.

Workflow Comparison: Manual vs Automated Fulfillment

Pick and pack workflows rely heavily on manual labor, where workers navigate warehouse aisles to locate and pick individual items before packing them for shipment, often resulting in longer fulfillment times and increased error rates. Goods-to-person systems automate item retrieval by using conveyor belts or robotic shuttles to deliver products directly to workers, significantly increasing efficiency and accuracy in order fulfillment. This automated fulfillment process reduces physical strain on employees and optimizes warehouse space utilization, driving faster throughput and higher operational productivity.

Efficiency and Productivity Metrics

Pick and Pack systems rely on workers manually selecting items from shelves, which can lead to longer order fulfillment times and higher labor costs, reflected in lower picks per hour and increased error rates. Goods-to-Person automation significantly boosts efficiency by delivering items directly to employees, resulting in higher throughput, improved accuracy rates above 99%, and reduced walking time measured in seconds per pick. Productivity metrics such as orders processed per hour demonstrate a 30-50% increase in Goods-to-Person systems compared to traditional Pick and Pack methods.

Technology Integration in Picking Methods

Technology integration in picking methods significantly enhances warehousing efficiency. Pick and Pack systems leverage barcode scanners and warehouse management software (WMS) for accurate order fulfillment, while Goods-to-Person technology uses automated storage and retrieval systems (AS/RS) paired with robotics to deliver items directly to workers, reducing travel time and errors. Implementing these technologies optimizes inventory accuracy, increases throughput, and supports scalable warehouse operations.

Labor Requirements and Operational Costs

Pick and Pack systems demand higher labor requirements due to manual item selection and sorting, increasing operational costs linked to wages and training. Goods-to-Person automation significantly reduces labor needs by using automated storage and retrieval systems to deliver items directly to workers, cutting down staffing expenses and minimizing errors. This technology investment elevates upfront costs but generates long-term savings through improved efficiency and reduced labor overhead in warehousing operations.

Scalability and Flexibility Considerations

Pick and Pack systems offer high flexibility by allowing manual selection of items for diverse order profiles, making them suitable for small to medium-sized operations with variable SKU ranges. Goods-to-Person (G2P) automation boosts scalability by increasing throughput and reducing labor dependency, ideal for large warehouses handling high order volumes and standardized products. Deciding between these methods hinges on balancing the need for adaptability in order picking against the demand for scalable, automated solutions that optimize space and labor efficiency.

Error Rates and Order Accuracy Analysis

Pick and Pack systems generally exhibit higher error rates due to manual item selection, leading to decreased order accuracy. Goods-to-Person technologies utilize automated retrieval, significantly reducing picking errors and improving order fulfillment precision. Studies indicate that implementing Goods-to-Person solutions can increase order accuracy by up to 99% compared to traditional Pick and Pack methods.

Choosing the Right Solution for Your Warehouse

Selecting between Pick and Pack and Goods-to-Person systems depends on order volume, SKU diversity, and warehouse layout. Pick and Pack is ideal for warehouses with moderate order volumes and diverse SKUs, enabling efficient manual picking and consolidation. Goods-to-Person automates item retrieval, reducing picker travel time and boosting accuracy, making it suitable for high-volume operations with repetitive picking tasks.

Related Important Terms

Micro-Fulfillment

Micro-fulfillment centers increasingly adopt Goods-to-Person (G2P) systems, which enhance picking accuracy and speed by delivering items directly to operators, reducing travel time compared to traditional Pick and Pack methods. This shift optimizes space utilization and order processing efficiency, critical for high-density urban warehouses focused on rapid delivery.

Robotic Pick-and-Pack

Robotic pick-and-pack systems enhance warehouse efficiency by automating item retrieval and packaging, reducing human error and accelerating order fulfillment compared to traditional goods-to-person methods. These systems leverage advanced robotics and AI to optimize space utilization and workflow, driving higher throughput and scalability in modern warehousing operations.

Augmented Reality Picking

Augmented Reality Picking in warehousing significantly enhances the efficiency of Pick and Pack processes by providing workers with real-time visual guidance and error reduction through smart glasses or AR headsets. In contrast, Goods-to-Person systems automate material delivery to the picker, but AR technology uniquely optimizes manual picking accuracy and speed without extensive infrastructure changes.

Automated Goods-to-Person (AG2P)

Automated Goods-to-Person (AG2P) systems enhance warehousing efficiency by delivering items directly to workers, significantly reducing travel time and increasing order accuracy compared to traditional Pick and Pack methods. AG2P integrates robotics and automation technologies to streamline inventory retrieval, accelerating fulfillment processes in high-volume distribution centers.

Batch Picking Optimization

Batch picking optimization significantly enhances efficiency in both Pick and Pack and Goods-to-Person systems by reducing travel time and consolidating multiple orders into single picking routes. Goods-to-Person technology streamlines batch picking further by bringing items directly to the worker, minimizing manual handling and increasing throughput compared to traditional Pick and Pack methods.

Dynamic Slotting

Dynamic slotting enhances Pick and Pack efficiency by continuously optimizing item locations based on real-time demand patterns, reducing travel time and increasing picking accuracy. In contrast, Goods-to-Person systems leverage automation to deliver items directly to workers, minimizing physical movement while dynamic slotting adapts storage layouts to maximize throughput in both methods.

Put-to-Light Systems

Put-to-Light systems enhance Pick and Pack efficiency by using illuminated indicators to guide warehouse operators quickly and accurately during order fulfillment. Compared to Goods-to-Person methods, Put-to-Light technology reduces errors and accelerates sorting processes, optimizing throughput in high-volume distribution centers.

Tote-to-Person Robotics

Pick and Pack systems rely on manual labor to select and package items, often leading to slower processing times and higher error rates compared to Tote-to-Person robotics, which automate the retrieval and delivery of totes directly to workers. Tote-to-Person robotics optimize warehouse efficiency by reducing travel time, enhancing accuracy, and enabling higher throughput in order fulfillment operations.

Zone-Based Picking

Zone-based picking divides warehouse areas into distinct zones where workers pick items specific to their assigned section, enhancing efficiency by reducing travel time. This method contrasts with goods-to-person systems that use automation to deliver items directly to pickers, favoring human labor organization over robotic assistance in zone-based picking.

Pick-by-Vision

Pick-by-Vision technology enhances the Pick and Pack process by using augmented reality to guide workers visually, reducing errors and increasing speed compared to traditional manual picking methods. In contrast, Goods-to-Person systems automate the retrieval of items to the worker's station, but Pick-by-Vision offers greater flexibility and scalability without extensive conveyor infrastructure.

Pick and Pack vs Goods-to-Person Infographic

industrydif.com

industrydif.com