Warehouses typically offer large-scale storage with extensive inventory capacity, supporting bulk order fulfillment and long-term stock management. Micro-fulfillment centers are smaller, strategically located facilities designed for rapid order processing and last-mile delivery, optimizing speed and efficiency in urban areas. Choosing between warehouse and micro-fulfillment depends on business goals such as volume, delivery speed, and geographic customer distribution.

Table of Comparison

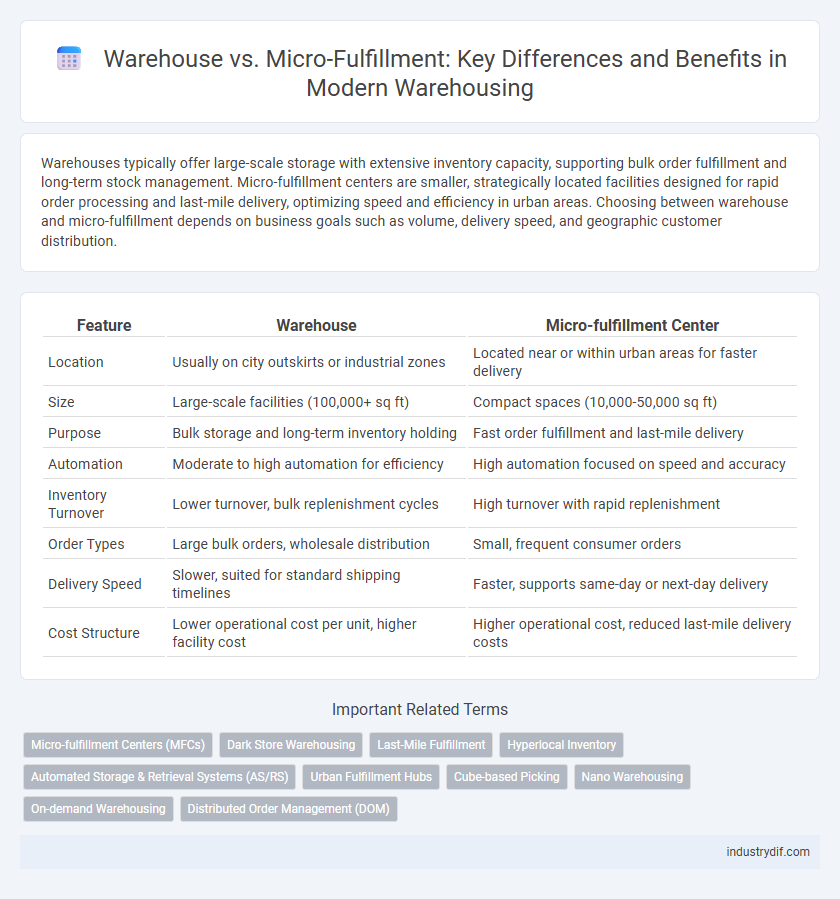

| Feature | Warehouse | Micro-fulfillment Center |

|---|---|---|

| Location | Usually on city outskirts or industrial zones | Located near or within urban areas for faster delivery |

| Size | Large-scale facilities (100,000+ sq ft) | Compact spaces (10,000-50,000 sq ft) |

| Purpose | Bulk storage and long-term inventory holding | Fast order fulfillment and last-mile delivery |

| Automation | Moderate to high automation for efficiency | High automation focused on speed and accuracy |

| Inventory Turnover | Lower turnover, bulk replenishment cycles | High turnover with rapid replenishment |

| Order Types | Large bulk orders, wholesale distribution | Small, frequent consumer orders |

| Delivery Speed | Slower, suited for standard shipping timelines | Faster, supports same-day or next-day delivery |

| Cost Structure | Lower operational cost per unit, higher facility cost | Higher operational cost, reduced last-mile delivery costs |

Introduction to Warehousing and Micro-fulfillment

Warehousing involves storing large volumes of goods in centralized facilities designed for inventory management and distribution efficiency. Micro-fulfillment centers are smaller, automated warehouses positioned closer to consumers, enabling rapid order processing and last-mile delivery. These two approaches address different logistical challenges by balancing scale, speed, and proximity to demand points.

Defining Traditional Warehousing

Traditional warehousing involves storing large quantities of goods in centralized facilities designed for long-term inventory management and bulk handling. These warehouses prioritize maximizing storage capacity and efficient space utilization, often accommodating diverse product ranges with standard shelving and pallet racking systems. Operations focus on receiving, storing, and shipping products in large batches, supporting supply chain activities such as distribution, replenishment, and order fulfillment at scale.

What is Micro-fulfillment?

Micro-fulfillment refers to a logistics strategy that uses small, highly automated warehouses located close to customers to speed up order processing and delivery. These facilities leverage robotics, AI, and real-time inventory management to efficiently handle e-commerce and omnichannel order fulfillment in urban areas. Micro-fulfillment centers complement traditional warehouses by reducing last-mile delivery times and optimizing supply chain responsiveness.

Key Differences Between Warehousing and Micro-fulfillment

Warehousing involves large-scale storage facilities designed for bulk inventory management, optimized for long-term storage and efficient space utilization. Micro-fulfillment centers prioritize speed and proximity to consumers, using automated systems to process small orders rapidly within urban or retail environments. Key differences include scale, automation level, fulfillment speed, and location strategy, with warehousing focusing on capacity and micro-fulfillment emphasizing last-mile delivery efficiency.

Space Utilization and Footprint Comparison

Warehouse facilities typically require large square footage to store inventory, leading to higher space utilization but a larger physical footprint. Micro-fulfillment centers prioritize compact, automated storage systems that maximize vertical space, significantly reducing the overall footprint while maintaining efficient inventory management. This compact design supports urban deployment where real estate costs and space are limited, optimizing operational efficiency in high-density markets.

Technology Integration and Automation

Warehouse operations increasingly integrate advanced technologies such as warehouse management systems (WMS), robotics, and IoT sensors to optimize inventory control and streamline order fulfillment processes. Micro-fulfillment centers leverage automation technologies like autonomous mobile robots (AMRs) and AI-driven picking systems to enable rapid order processing within urban retail environments, minimizing delivery times. The convergence of scalable automation and real-time data analytics enhances both traditional warehouse efficiency and micro-fulfillment agility, supporting responsive supply chain management.

Cost Implications and ROI

Warehouse operations typically incur higher fixed costs due to larger space requirements, labor, and inventory management systems, while micro-fulfillment centers optimize last-mile delivery costs by utilizing smaller footprints closer to consumers. Micro-fulfillment offers faster order processing and reduced transportation expenses, enhancing ROI through improved customer satisfaction and lower delivery times. Investment in automation technology for micro-fulfillment can yield significant cost savings and efficiency gains compared to traditional warehouse models.

Speed and Efficiency in Order Fulfillment

Warehouse operations leverage large storage capacity and advanced inventory management systems to handle bulk orders efficiently, optimizing space and reducing per-unit storage costs. Micro-fulfillment centers prioritize speed by positioning inventory closer to customers, enabling rapid picking and same-day delivery for high-demand products. Combining macro warehouses with micro-fulfillment hubs enhances overall supply chain agility, balancing cost efficiency with fast order fulfillment.

Scalability and Adaptability for Businesses

Warehouse facilities offer extensive scalability with large storage capacities and the ability to handle a high volume of products, making them suitable for businesses anticipating significant growth. Micro-fulfillment centers emphasize adaptability through compact operations located near urban areas, providing faster order processing and flexible inventory management. Businesses balancing large-scale distribution with rapid, localized fulfillment often integrate both models to optimize scalability and responsiveness.

Choosing the Right Solution for Your Supply Chain

Selecting the appropriate warehousing solution depends on your supply chain's scale, delivery speed, and inventory complexity. Traditional warehouses offer large storage capacity and centralized inventory management, ideal for bulk goods and long-term stockholding. Micro-fulfillment centers deliver rapid order processing and localized distribution, enhancing last-mile delivery efficiency for e-commerce and high-demand, small-item fulfillment.

Related Important Terms

Micro-fulfillment Centers (MFCs)

Micro-fulfillment centers (MFCs) leverage advanced automation and AI-driven inventory management to enable rapid order processing within urban areas, significantly reducing last-mile delivery times compared to traditional warehouses. These compact facilities optimize space and labor efficiency, making them essential for e-commerce businesses aiming to meet growing consumer demand for same-day or next-day delivery.

Dark Store Warehousing

Dark store warehousing operates as a hybrid between traditional warehouses and micro-fulfillment centers, optimized for rapid e-commerce order processing within urban areas. Unlike standard warehouses, dark stores focus on inventory agility and proximity to consumers, significantly reducing last-mile delivery times and enhancing fulfillment efficiency.

Last-Mile Fulfillment

Micro-fulfillment centers enhance last-mile fulfillment by enabling faster delivery through smaller, strategically located facilities near urban areas, reducing transit times and transportation costs compared to traditional large warehouses. Leveraging automation and proximity to consumers, micro-fulfillment optimizes inventory management and meets the growing demand for rapid, flexible e-commerce fulfillment.

Hyperlocal Inventory

Hyperlocal inventory in warehouse operations enables faster order fulfillment by storing products closer to end consumers, reducing delivery times and transportation costs. Micro-fulfillment centers utilize automated systems within smaller warehouse spaces to optimize hyperlocal inventory management, enhancing efficiency and meeting the demand for rapid, last-mile delivery.

Automated Storage & Retrieval Systems (AS/RS)

Automated Storage & Retrieval Systems (AS/RS) enhance efficiency in both traditional warehouses and micro-fulfillment centers by enabling rapid, accurate inventory handling with minimal human intervention. While warehouses benefit from AS/RS in managing large-scale storage and bulk inventory, micro-fulfillment centers leverage these systems to optimize space and accelerate last-mile delivery for e-commerce fulfillment.

Urban Fulfillment Hubs

Urban fulfillment hubs leverage micro-fulfillment centers to maximize space efficiency and accelerate last-mile delivery in congested city environments, outperforming traditional large-scale warehouses in speed and proximity to consumers. These compact, technology-driven hubs support omnichannel retail strategies by enabling rapid order processing and reducing transportation costs within dense urban markets.

Cube-based Picking

Cube-based picking in warehouse operations optimizes storage density and picking efficiency by utilizing cubic space to store inventory, which contrasts with micro-fulfillment centers that prioritize speed and proximity for smaller, more frequent orders. Warehouses leverage cube-based picking to maximize space utilization for bulk inventory, while micro-fulfillment systems focus on automation and rapid picking in compact spaces to serve e-commerce and last-mile delivery demands.

Nano Warehousing

Nano warehousing revolutionizes traditional warehouse models and micro-fulfillment centers by enabling ultra-compact storage solutions optimized for last-mile delivery and rapid order processing within limited urban spaces. This emerging warehousing approach maximizes space efficiency through automation and smart inventory management, reducing transportation costs and accelerating fulfillment speed.

On-demand Warehousing

On-demand warehousing offers flexible storage solutions that allow businesses to scale inventory space dynamically, contrasting with traditional warehouses designed for long-term storage; micro-fulfillment centers emphasize rapid, localized order processing to enhance last-mile delivery efficiency. Leveraging on-demand warehousing reduces overhead by optimizing unused warehouse capacity, while micro-fulfillment improves delivery speed through automated, small-scale facilities situated near customers.

Distributed Order Management (DOM)

Distributed Order Management (DOM) enhances warehouse efficiency by intelligently routing orders between centralized warehouses and micro-fulfillment centers based on real-time inventory and demand data. This strategic allocation reduces delivery times, optimizes stock levels, and supports seamless omnichannel fulfillment across diverse distribution points.

Warehouse vs Micro-fulfillment Infographic

industrydif.com

industrydif.com