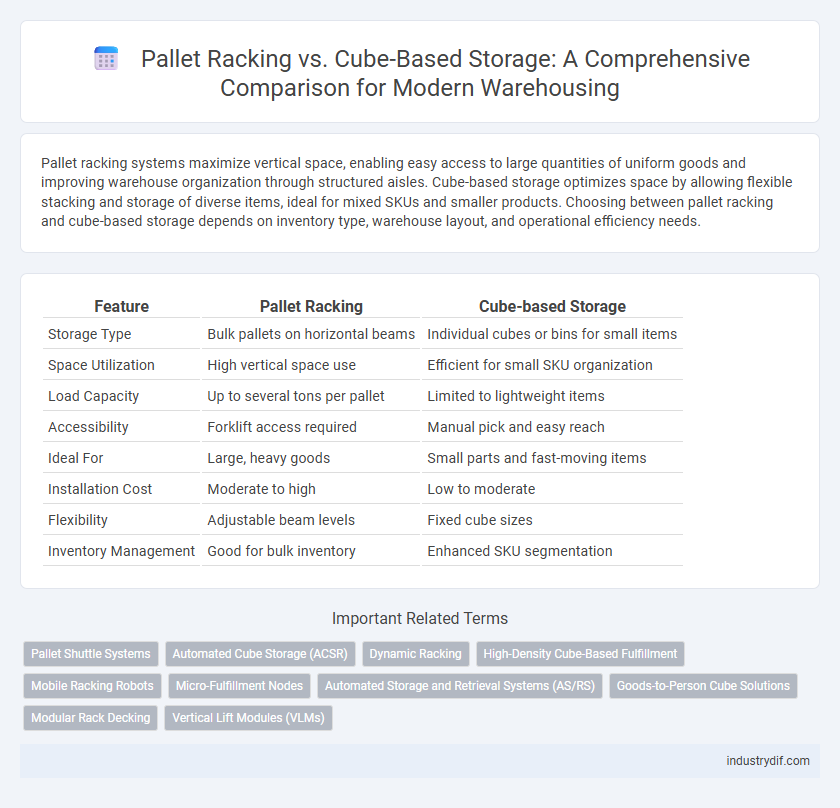

Pallet racking systems maximize vertical space, enabling easy access to large quantities of uniform goods and improving warehouse organization through structured aisles. Cube-based storage optimizes space by allowing flexible stacking and storage of diverse items, ideal for mixed SKUs and smaller products. Choosing between pallet racking and cube-based storage depends on inventory type, warehouse layout, and operational efficiency needs.

Table of Comparison

| Feature | Pallet Racking | Cube-based Storage |

|---|---|---|

| Storage Type | Bulk pallets on horizontal beams | Individual cubes or bins for small items |

| Space Utilization | High vertical space use | Efficient for small SKU organization |

| Load Capacity | Up to several tons per pallet | Limited to lightweight items |

| Accessibility | Forklift access required | Manual pick and easy reach |

| Ideal For | Large, heavy goods | Small parts and fast-moving items |

| Installation Cost | Moderate to high | Low to moderate |

| Flexibility | Adjustable beam levels | Fixed cube sizes |

| Inventory Management | Good for bulk inventory | Enhanced SKU segmentation |

Introduction to Warehousing Storage Systems

Pallet racking maximizes vertical space by storing goods on pallets arranged in rows and columns, offering easy access with forklifts and supporting heavy loads, making it ideal for high-volume warehouses. Cube-based storage leverages modular, stackable units to create dense storage zones optimized for smaller items or mixed inventory types, enhancing organization and retrieval speed. Choosing between these systems depends on inventory size, turnover rate, and warehouse layout to optimize space utilization and operational efficiency.

Overview of Pallet Racking

Pallet racking systems offer high-density storage by utilizing vertical space efficiently, supporting heavy loads on standardized pallets. These racking solutions enhance warehouse organization and accessibility, enabling quick inventory retrieval and optimal space utilization. Common types include selective, drive-in, and push-back racks, each designed to meet specific operational needs and maximize storage capacity.

Overview of Cube-based Storage

Cube-based storage maximizes vertical space utilization by storing goods in modular, cube-shaped compartments, enabling efficient organization and easy accessibility. It is ideal for inventories with diverse product sizes and frequent stock rotation, reducing material handling time and improving workflow. This system supports inventory accuracy and scalability, making it a preferred choice for dynamic warehouse operations.

Space Utilization Efficiency Comparison

Pallet racking systems offer high vertical space utilization by allowing multiple pallet loads to be stacked efficiently, maximizing warehouse floor space while facilitating easy forklift access. Cube-based storage optimizes volume utilization by using modular cubes that fit items snugly, reducing wasted air space and improving organization for smaller or irregularly shaped goods. Comparing both, pallet racking excels in handling large, uniform pallets with vertical efficiency, whereas cube-based storage enhances overall space utilization for diverse inventory with intricate storage needs.

Flexibility and Scalability in Warehousing

Pallet racking offers superior flexibility by accommodating various pallet sizes and weights, enabling efficient organization of bulk inventory in warehouses. Cube-based storage maximizes vertical space utilization and allows modular expansion, enhancing scalability for growing warehouse operations. Combining both systems can optimize storage density and adapt to fluctuating inventory demands, promoting operational agility.

Operational Workflow Impacts

Pallet racking systems enhance operational workflow by enabling easy access to individual pallets, reducing pick times and improving inventory management accuracy in large warehouses. Cube-based storage maximizes space utilization through dense stacking but may increase retrieval time and require more complex inventory tracking systems. Efficient warehouse operations depend on balancing accessibility with storage density to optimize picking speed and overall productivity.

Cost Analysis and ROI

Pallet racking systems typically offer lower initial costs and higher storage density per square foot compared to cube-based storage, making them cost-efficient for bulkier inventory. Cube-based storage, while having higher upfront investment due to modular shelving and automation, can maximize vertical space utilization and improve pick accuracy, leading to faster order fulfillment and reduced labor costs. Analyzing ROI, pallet racking tends to deliver quicker payback in high-volume, homogeneous product environments, whereas cube-based systems provide better long-term returns in complex, SKU-diverse operations requiring flexibility and speed.

Safety and Risk Management

Pallet racking systems offer enhanced safety through sturdy steel frameworks that secure heavy loads and minimize collapse risks compared to cube-based storage, which often involves stacked boxes with less structural support. Implementing pallet racking reduces hazards such as falling items and enables better organization for emergency access, thus improving overall risk management in warehousing operations. Regular inspections and compliance with OSHA standards ensure that pallet racking maintains its safety integrity, making it a preferred choice for high-density, heavy-duty storage environments.

Industry Use Cases

Pallet racking systems are ideal for industries requiring high-density storage of bulky goods, such as manufacturing, automotive, and wholesale distribution, enabling efficient horizontal space utilization and easy forklift access. Cube-based storage is preferred in e-commerce, retail, and pharmaceutical sectors where mixed SKU storage, fast picking, and inventory visibility are critical, supporting smaller, varied product sizes. Selecting between these systems depends on product volume, handling equipment, and operational workflow to maximize warehouse efficiency and throughput.

Choosing the Right System for Your Warehouse

Pallet racking systems maximize vertical storage and are ideal for warehouses handling heavy, bulky items requiring easy forklift access, while cube-based storage optimizes space for smaller, uniform products with high SKU counts. Evaluating inventory type, picking frequency, and space availability ensures selecting a system that enhances efficiency and supports warehouse throughput. Integrating the right storage solution reduces handling times and improves overall warehouse organization and inventory management.

Related Important Terms

Pallet Shuttle Systems

Pallet shuttle systems enhance pallet racking efficiency by automating the horizontal movement of pallets within dense storage lanes, optimizing space utilization and reducing labor costs compared to cube-based storage solutions. These systems increase throughput and provide faster access to inventory, making them ideal for high-volume warehouses requiring scalable, dynamic storage environments.

Automated Cube Storage (ACSR)

Automated Cube Storage (ACSR) offers high-density storage with rapid retrieval speeds, maximizing warehouse space utilization compared to traditional pallet racking systems. Advanced robotics and computerized controls in ACSR enhance inventory accuracy and reduce labor costs, making it ideal for warehouses with diverse SKU profiles and limited floor space.

Dynamic Racking

Dynamic racking systems in warehousing, such as pallet flow racks and push-back racks, optimize space utilization and improve inventory rotation by using gravity or spring mechanisms to move pallets efficiently. Compared to cube-based storage, dynamic racking maximizes pallet accessibility and reduces handling time, leading to higher throughput and streamlined order fulfillment processes.

High-Density Cube-Based Fulfillment

High-density cube-based fulfillment optimizes warehouse space by utilizing vertical storage and minimizing aisle widths, significantly increasing storage capacity compared to traditional pallet racking systems. This method enhances picking efficiency and inventory accessibility, making it ideal for e-commerce and fast-moving consumer goods operations requiring compact, scalable storage solutions.

Mobile Racking Robots

Mobile racking robots enhance pallet racking systems by maximizing vertical space utilization and enabling efficient, automated inventory retrieval, outperforming traditional cube-based storage in storage density and operational speed. These robots reduce labor costs and increase throughput by navigating narrow aisles and dynamically adjusting rack configurations, making them ideal for high-volume warehouses seeking scalable automation solutions.

Micro-Fulfillment Nodes

Pallet racking systems maximize vertical space by storing standardized pallets, enabling high-density inventory management crucial for micro-fulfillment nodes seeking rapid product turnover. Cube-based storage enhances SKU differentiation and order accuracy in micro-fulfillment environments by utilizing modular bins and automated retrieval, optimizing compact footprint usage for last-mile delivery efficiency.

Automated Storage and Retrieval Systems (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) integrated with pallet racking maximize vertical space utilization and enable high-density storage with rapid access to heavy or bulky items. Cube-based storage paired with AS/RS offers enhanced flexibility for mixed SKU environments by supporting diverse product sizes while optimizing order picking efficiency.

Goods-to-Person Cube Solutions

Goods-to-Person cube-based storage solutions maximize warehouse space utilization by automating item retrieval and minimizing travel time, significantly increasing order picking efficiency compared to traditional pallet racking systems. These cube solutions leverage vertical space and compact storage density, reducing labor costs and enhancing inventory accuracy for high-throughput environments.

Modular Rack Decking

Modular rack decking in pallet racking systems offers enhanced flexibility and load capacity compared to cube-based storage by allowing customizable shelf configurations that maximize vertical space utilization. This adaptability supports diverse inventory sizes and weights, optimizing warehouse efficiency and scalability.

Vertical Lift Modules (VLMs)

Vertical Lift Modules (VLMs) maximize vertical space utilization by automatically retrieving items from dense, enclosed storage trays, offering higher storage density and enhanced inventory accuracy compared to traditional pallet racking which relies on manual access and larger aisle clearance. Cube-based storage systems optimize floor space through compact, modular units but lack the dynamic retrieval efficiency and scalability found in VLMs, making VLMs ideal for high-throughput warehouses requiring quick, precise order fulfillment.

Pallet Racking vs Cube-based Storage Infographic

industrydif.com

industrydif.com