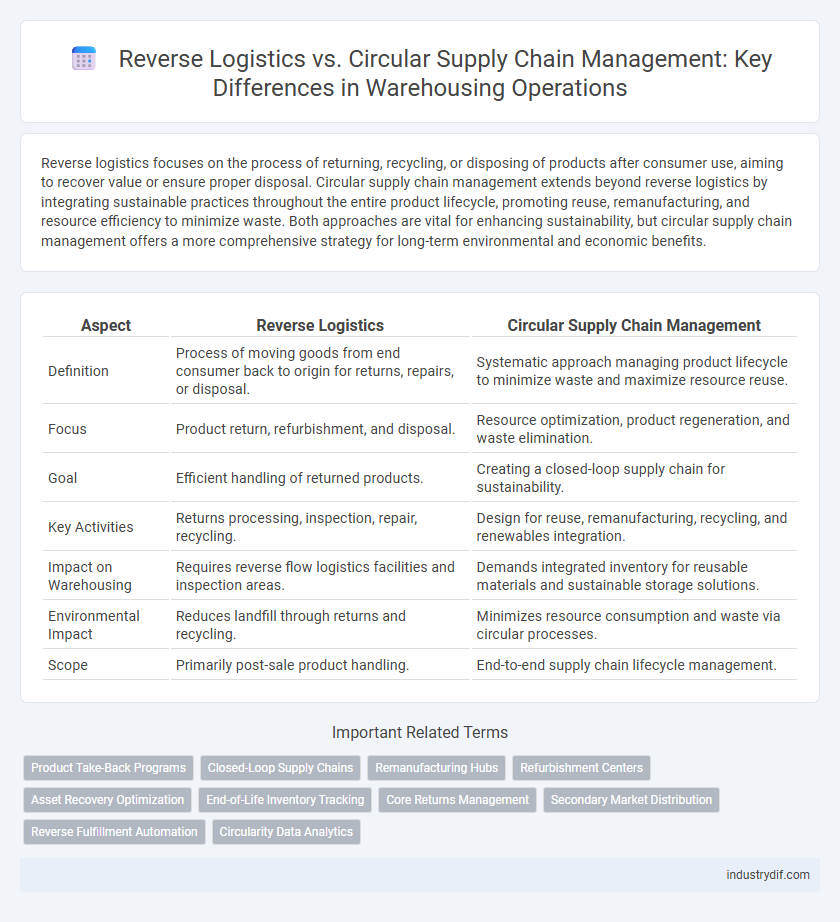

Reverse logistics focuses on the process of returning, recycling, or disposing of products after consumer use, aiming to recover value or ensure proper disposal. Circular supply chain management extends beyond reverse logistics by integrating sustainable practices throughout the entire product lifecycle, promoting reuse, remanufacturing, and resource efficiency to minimize waste. Both approaches are vital for enhancing sustainability, but circular supply chain management offers a more comprehensive strategy for long-term environmental and economic benefits.

Table of Comparison

| Aspect | Reverse Logistics | Circular Supply Chain Management |

|---|---|---|

| Definition | Process of moving goods from end consumer back to origin for returns, repairs, or disposal. | Systematic approach managing product lifecycle to minimize waste and maximize resource reuse. |

| Focus | Product return, refurbishment, and disposal. | Resource optimization, product regeneration, and waste elimination. |

| Goal | Efficient handling of returned products. | Creating a closed-loop supply chain for sustainability. |

| Key Activities | Returns processing, inspection, repair, recycling. | Design for reuse, remanufacturing, recycling, and renewables integration. |

| Impact on Warehousing | Requires reverse flow logistics facilities and inspection areas. | Demands integrated inventory for reusable materials and sustainable storage solutions. |

| Environmental Impact | Reduces landfill through returns and recycling. | Minimizes resource consumption and waste via circular processes. |

| Scope | Primarily post-sale product handling. | End-to-end supply chain lifecycle management. |

Introduction to Reverse Logistics and Circular Supply Chains

Reverse logistics involves the process of moving goods from their final destination back to the manufacturer or warehouse for the purpose of return, repair, remanufacture, or recycling. Circular supply chain management integrates reverse logistics with sustainable practices, emphasizing resource recovery, waste minimization, and product life extension to create a closed-loop system. Both concepts are essential in modern warehousing for enhancing sustainability and operational efficiency.

Key Differences Between Reverse Logistics and Circular Supply Chain Management

Reverse logistics primarily focuses on the process of moving goods from the end consumer back to the manufacturer for returns, refurbishing, or disposal, while circular supply chain management emphasizes designing production systems that reuse resources to eliminate waste and extend product life cycles. Reverse logistics operates within the traditional linear supply chain model, handling returns and recycling as corrective steps, whereas circular supply chain management integrates sustainability principles throughout the supply network to achieve closed-loop flows. Key differences include scope, with reverse logistics being reactive and operational, and circular supply chain management being proactive and strategic in creating regenerative resource cycles.

Core Objectives of Reverse Logistics in Warehousing

Reverse logistics in warehousing primarily focuses on the efficient return, refurbishment, and disposal of products to minimize waste and recover value. This process ensures optimal inventory management by handling returns, recalls, and excess stock, reducing storage costs and improving sustainability. Core objectives include enhancing customer satisfaction through seamless returns processing and supporting environmental goals by promoting reuse and recycling within the supply chain.

Principles of Circular Supply Chain Management in Modern Industry

Circular Supply Chain Management in modern industry emphasizes resource efficiency, product lifecycle extension, and waste minimization through practices such as product design for reuse, remanufacturing, and closed-loop material flows. It integrates reverse logistics processes to enable return, refurbishment, and recycling of products, reducing environmental impact and fostering sustainability. Core principles include collaboration across supply chain partners, data-driven tracking of materials, and aligning economic goals with ecological responsibility.

Benefits of Implementing Reverse Logistics in Warehousing Operations

Implementing reverse logistics in warehousing operations enhances inventory management by efficiently handling returns, refurbishments, and recycling processes. This approach reduces waste and lowers disposal costs, contributing to a more sustainable supply chain. Streamlined reverse logistics also improves customer satisfaction through quicker processing of returned goods and accurate restocking.

Advantages of Adopting Circular Supply Chain Strategies

Adopting circular supply chain strategies enhances resource efficiency by promoting product reuse, remanufacturing, and recycling within warehousing operations, reducing waste and lowering costs. These strategies improve supply chain resilience through better inventory management and increased collaboration among suppliers, manufacturers, and reverse logistics providers. Implementing circular supply chains supports sustainability goals, minimizes environmental impact, and drives long-term economic value by extending product lifecycles and optimizing material flows.

Technological Innovations Supporting Reverse Logistics

Technological innovations such as IoT-enabled tracking systems, advanced robotics, and AI-driven analytics significantly enhance reverse logistics by optimizing product returns, refurbishing, and recycling processes within warehousing operations. Automated sorting and real-time inventory management reduce turnaround times and operational costs, directly supporting efficient goods recovery and reintegration. These innovations create a streamlined reverse flow of materials, fostering more sustainable practices aligned with circular supply chain management principles.

Sustainability Impacts: Reverse Logistics vs Circular Supply Chains

Reverse logistics focuses on the efficient return, recycling, and disposal of products to minimize waste and reduce environmental impact. Circular supply chain management extends this by designing closed-loop systems that prioritize resource reuse, continuous product life cycles, and waste elimination, significantly enhancing sustainability. Implementing circular supply chains leads to greater reductions in carbon footprint and raw material consumption compared to traditional reverse logistics processes.

Challenges and Solutions in Integrating Both Approaches

Reverse logistics faces challenges in managing returned goods efficiently, leading to high operational costs and complexity in inventory tracking. Circular supply chain management struggles with designing closed-loop systems that balance sustainability goals and profitability while ensuring material quality and reuse. Integrating both approaches requires advanced data analytics, cross-functional collaboration, and technology adoption such as IoT and AI to optimize return flows, enhance traceability, and support sustainable resource management.

Future Trends in Warehousing: The Convergence of Reverse Logistics and Circular Supply Chain Management

Future trends in warehousing highlight the convergence of reverse logistics and circular supply chain management to enhance sustainability and operational efficiency. Advanced technologies such as AI and IoT enable real-time tracking and optimization of returns, repairs, and recycling within warehouse operations. This integration supports a closed-loop system that reduces waste, lowers costs, and promotes resource recovery in supply chains.

Related Important Terms

Product Take-Back Programs

Product take-back programs in reverse logistics emphasize efficiently collecting used products for refurbishment, recycling, or disposal, thereby reducing waste and minimizing environmental impact. Circular supply chain management integrates these programs within a broader system that maximizes resource recovery, extends product life cycles, and promotes sustainable material flows across all supply chain stages.

Closed-Loop Supply Chains

Closed-loop supply chains emphasize the integration of reverse logistics processes to recover value from used products through refurbishment, remanufacturing, and recycling, enabling sustainable resource management and waste reduction. Reverse logistics serves as a critical component within circular supply chain management by efficiently handling product returns, minimizing environmental impact, and supporting the continuous flow of materials back into the production cycle.

Remanufacturing Hubs

Remanufacturing hubs play a crucial role in reverse logistics by efficiently processing returned goods to restore them to like-new condition, reducing waste and resource consumption. In circular supply chain management, these hubs facilitate closed-loop systems that enhance sustainability through continuous product reuse and lifecycle extension.

Refurbishment Centers

Refurbishment centers play a pivotal role in reverse logistics by efficiently processing returned or damaged goods for repair and resale, minimizing waste and maximizing asset recovery. In circular supply chain management, these centers integrate sustainable practices to extend product life cycles, reduce raw material consumption, and promote a closed-loop system.

Asset Recovery Optimization

Reverse logistics concentrates on the efficient return and disposition of goods to maximize value recovery, emphasizing processes such as refurbishment, remanufacturing, and recycling within warehousing operations. Circular supply chain management extends this by integrating asset recovery optimization into a closed-loop system, promoting sustainability through continuous reuse of materials and minimizing waste across the entire product lifecycle.

End-of-Life Inventory Tracking

Reverse logistics emphasizes the efficient retrieval and processing of end-of-life inventory to minimize waste and recover value through refurbishment or recycling. Circular supply chain management integrates end-of-life inventory tracking with product lifecycle data to optimize resource reuse, extend asset life, and support sustainable warehousing operations.

Core Returns Management

Core Returns Management in reverse logistics prioritizes efficient processing, inspection, and refurbishment of returned products to maximize recovery value and minimize waste. Circular Supply Chain Management integrates this returns process into a broader system that emphasizes product lifecycle extension, resource recirculation, and sustainable inventory replenishment within warehousing operations.

Secondary Market Distribution

Reverse logistics centers on the efficient return, refurbishment, and redistribution of products from consumers to warehouses, optimizing secondary market distribution by minimizing waste and reducing storage costs. Circular supply chain management extends this concept by integrating sustainability practices and product lifecycle management, ensuring materials and products continuously flow through secondary markets, enhancing resource recovery and prolonging asset value.

Reverse Fulfillment Automation

Reverse fulfillment automation in reverse logistics accelerates the processing of returned goods by integrating advanced tracking systems and robotic sorting, reducing handling time and operational costs. Circular supply chain management emphasizes product lifecycle extension and material reuse, where reverse fulfillment automation ensures seamless return flows that support sustainability goals by efficiently reinserting products into the supply chain.

Circularity Data Analytics

Circularity data analytics in circular supply chain management leverages real-time tracking of product lifecycle metrics and waste reduction KPIs to optimize resource recirculation and enhance sustainability. Unlike traditional reverse logistics, which primarily focuses on product returns and disposal processes, circularity analytics drives decision-making by integrating end-of-life data to maximize material reuse, remanufacturing, and recycling efficiency within warehousing operations.

Reverse Logistics vs Circular Supply Chain Management Infographic

industrydif.com

industrydif.com