First In First Out (FIFO) prioritizes moving older stock before newer items, reducing spoilage and ensuring product freshness in warehouse management. Just-In-Case Inventory maintains higher stock levels to prevent shortages and meet unexpected demand spikes, enhancing operational resilience. Balancing FIFO and Just-In-Case strategies optimizes inventory turnover while safeguarding against supply chain disruptions.

Table of Comparison

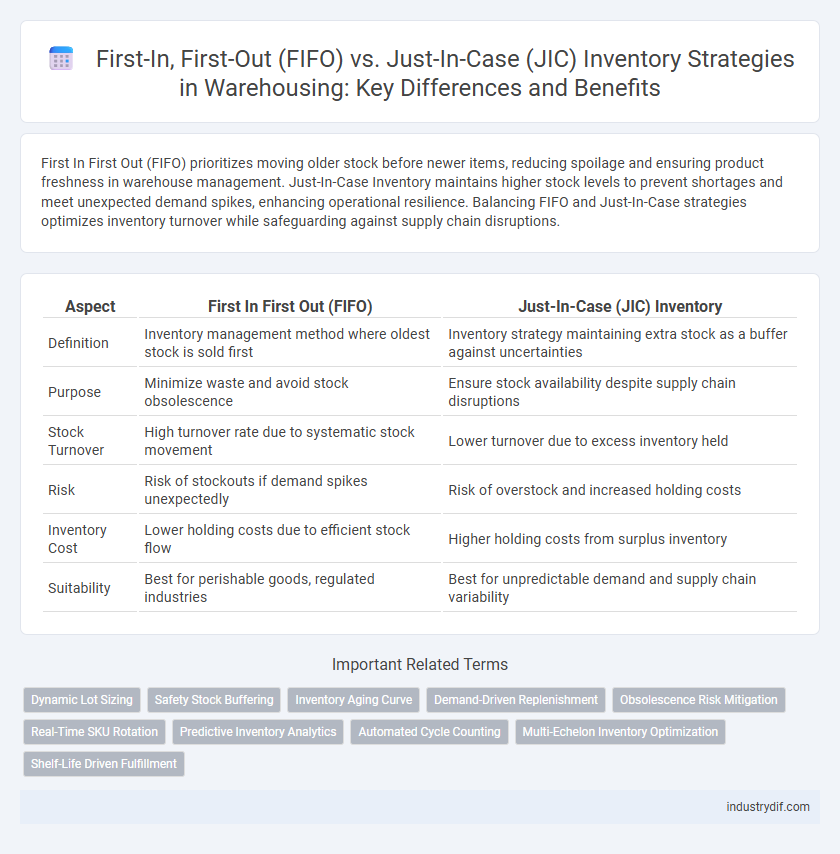

| Aspect | First In First Out (FIFO) | Just-In-Case (JIC) Inventory |

|---|---|---|

| Definition | Inventory management method where oldest stock is sold first | Inventory strategy maintaining extra stock as a buffer against uncertainties |

| Purpose | Minimize waste and avoid stock obsolescence | Ensure stock availability despite supply chain disruptions |

| Stock Turnover | High turnover rate due to systematic stock movement | Lower turnover due to excess inventory held |

| Risk | Risk of stockouts if demand spikes unexpectedly | Risk of overstock and increased holding costs |

| Inventory Cost | Lower holding costs due to efficient stock flow | Higher holding costs from surplus inventory |

| Suitability | Best for perishable goods, regulated industries | Best for unpredictable demand and supply chain variability |

Understanding FIFO and Just-In-Case Inventory Strategies

First In First Out (FIFO) is an inventory management strategy where the oldest stock is used or sold first, minimizing spoilage and ensuring product freshness, especially critical in perishable goods warehousing. Just-In-Case inventory, on the other hand, maintains higher stock levels to mitigate risks from supply chain disruptions, demand surges, or lead time variability, enhancing warehouse resilience. Understanding FIFO versus Just-In-Case approaches helps optimize inventory turnover rates, reduce holding costs, and balance service levels with risk management in warehousing operations.

Key Principles of First In First Out (FIFO)

First In First Out (FIFO) inventory management prioritizes the rotation of stock based on the chronological order of arrival, ensuring older inventory is used before newer stock. This method minimizes spoilage, reduces obsolescence, and maintains product quality, especially crucial for perishable goods. FIFO enhances accuracy in inventory tracking and aligns with financial accounting standards by systematically matching costs with revenues.

Core Concepts Behind Just-In-Case Inventory

Just-In-Case Inventory centers on maintaining extra stock to mitigate risks from supply chain disruptions, demand fluctuations, or production delays. This strategy prioritizes resilience by holding buffer inventory, contrasting with more streamlined methods like First In First Out that focus on inventory turnover efficiency. Core concepts include safety stock levels, risk management, and ensuring continuous operations despite uncertainties in supply or demand.

Efficiency: FIFO vs Just-In-Case in Warehousing

First In First Out (FIFO) enhances warehousing efficiency by reducing inventory holding costs and minimizing product obsolescence through systematic stock rotation. Just-In-Case inventory prioritizes risk mitigation by maintaining surplus stock, which can lead to increased storage requirements and higher capital tied up in inventory. Optimizing warehouse operations requires balancing FIFO's lean inventory approach with Just-In-Case's buffer capacity to ensure timely order fulfillment and cost-effective space utilization.

Risk Management in Inventory Control Methods

First In First Out (FIFO) minimizes risk by ensuring older stock is sold first, reducing obsolescence and spoilage. Just-In-Case inventory emphasizes risk mitigation through buffer stock, protecting against supply chain disruptions but increasing holding costs. Effective risk management in warehousing balances FIFO's efficiency with Just-In-Case's safety stock to optimize inventory turnover and resilience.

Impact on Warehouse Storage and Layout

First In First Out (FIFO) inventory management streamlines warehouse storage by promoting organized shelving and efficient space utilization, minimizing the risk of stock obsolescence. In contrast, Just-In-Case (JIC) inventory requires larger storage capacity to accommodate excess stock, often leading to complex layout designs and higher holding costs. Optimizing warehouse layout for FIFO supports faster inventory turnover and better flow, whereas JIC demands flexible storage solutions to manage unpredictable demand surges.

Cost Implications of FIFO and Just-In-Case Systems

First In First Out (FIFO) inventory management reduces holding costs by minimizing the storage time and risk of obsolescence, enhancing cash flow and decreasing warehousing expenses. Just-In-Case inventory requires higher carrying costs due to larger safety stock levels, increasing capital tied up in inventory and the likelihood of waste from excess or expired goods. Businesses adopting FIFO often experience lower overall operational costs, while Just-In-Case models prioritize supply security at the expense of increased warehousing and inventory costs.

Technology Integration for Inventory Optimization

Technology integration in warehousing enables precise implementation of FIFO (First In First Out) systems by using RFID and barcode scanning to track item age and batch details in real-time, reducing spoilage and obsolescence. Just-In-Case inventory strategies benefit from advanced inventory management software and AI-driven demand forecasting to maintain safety stock levels without excessive overstocking. Combining IoT sensors and cloud-based analytics optimizes inventory turnover rates while balancing risks of stockouts and excess holding costs.

Industry Suitability: Choosing the Right Method

First In First Out (FIFO) is ideal for perishable goods industries like food and pharmaceuticals, ensuring inventory freshness and minimizing spoilage. Just-In-Case inventory suits sectors with unpredictable demand or supply chain disruptions, such as manufacturing and retail, by maintaining buffer stock to avoid stockouts. Selecting the right method depends on product shelf life, demand variability, and supply chain reliability within the specific industry.

Future Trends in Inventory Management Strategies

Future trends in inventory management increasingly favor First In First Out (FIFO) due to enhanced demand forecasting and automation technologies reducing waste and obsolescence. Just-In-Case (JIC) inventory strategies may decline as real-time data analytics and supply chain visibility improve, enabling leaner stock levels without risking stockouts. Integration of AI and IoT in warehousing facilities streamlines FIFO implementation, ensuring efficient turnover and cost savings for businesses adapting to dynamic market demands.

Related Important Terms

Dynamic Lot Sizing

Dynamic Lot Sizing optimizes inventory levels by adjusting order quantities based on demand forecasts, reducing excess stock inherent in Just-In-Case Inventory strategies while maintaining the FIFO principle to ensure older stock moves first. This approach enhances warehousing efficiency by minimizing holding costs and stock obsolescence, aligning production schedules closely with actual consumption patterns.

Safety Stock Buffering

First In First Out (FIFO) inventory management minimizes stock obsolescence by ensuring older items are sold before newer stock, optimizing warehouse efficiency and reducing holding costs. Just-In-Case inventory strategy emphasizes maintaining high safety stock buffers to mitigate supply chain disruptions, enhancing resilience but increasing storage expenses and capital tied up in inventory.

Inventory Aging Curve

The Inventory Aging Curve illustrates how First In First Out (FIFO) minimizes stock obsolescence by ensuring older inventory moves out before new arrivals, maintaining product freshness and reducing holding costs. In contrast, Just-In-Case inventory strategy often leads to a longer aging curve with increased risk of excess or expired stock due to bulk purchasing and overstocking.

Demand-Driven Replenishment

First In First Out (FIFO) optimizes warehousing by reducing product obsolescence and spoilage through demand-driven replenishment, ensuring older stock moves out before newer arrivals. Just-In-Case Inventory prioritizes safety stock levels to buffer demand variability, often increasing holding costs but minimizing stockouts in uncertain supply chain conditions.

Obsolescence Risk Mitigation

First In First Out (FIFO) inventory management minimizes obsolescence risk by ensuring older stock is sold before newer items, reducing the likelihood of inventory becoming outdated. Just-In-Case inventory increases obsolescence risk due to excess stock holding, potentially leading to higher storage costs and waste from unsold products.

Real-Time SKU Rotation

Real-time SKU rotation enables efficient First In First Out (FIFO) inventory management by ensuring older stock is dispatched before newer arrivals, reducing spoilage and obsolescence. In contrast, Just-In-Case inventory prioritizes stock availability over rotation speed, often leading to stagnant SKUs and increased holding costs.

Predictive Inventory Analytics

Predictive inventory analytics enhances FIFO by accurately forecasting demand and minimizing stock obsolescence, ensuring older inventory is efficiently rotated out. Contrastingly, Just-In-Case inventory benefits from predictive models by optimizing buffer stock levels to prevent stockouts without excessive overstocking.

Automated Cycle Counting

Automated cycle counting enhances First In First Out (FIFO) accuracy by systematically verifying stock rotation and reducing obsolete inventory risks inherent in Just-In-Case inventory strategies. Optimizing real-time data capture via RFID and barcode scanning strengthens inventory precision, minimizes stockouts, and supports lean warehousing operations.

Multi-Echelon Inventory Optimization

Multi-Echelon Inventory Optimization (MEIO) enhances warehouse efficiency by balancing First In First Out (FIFO) methods with Just-In-Case (JIC) inventory strategies, ensuring timely product flow while maintaining safety stock across multiple distribution layers. This approach reduces stockouts and excess inventory by dynamically allocating resources based on real-time demand forecasting and lead time variability at each echelon.

Shelf-Life Driven Fulfillment

Shelf-life driven fulfillment prioritizes First In First Out (FIFO) methodology to minimize product spoilage and ensure timely dispatch of perishable goods by rotating stock based on expiration dates. Just-In-Case inventory increases holding costs and risks obsolescence, making FIFO essential for efficient warehouse management of limited-shelf-life products.

First In First Out vs Just-In-Case Inventory Infographic

industrydif.com

industrydif.com