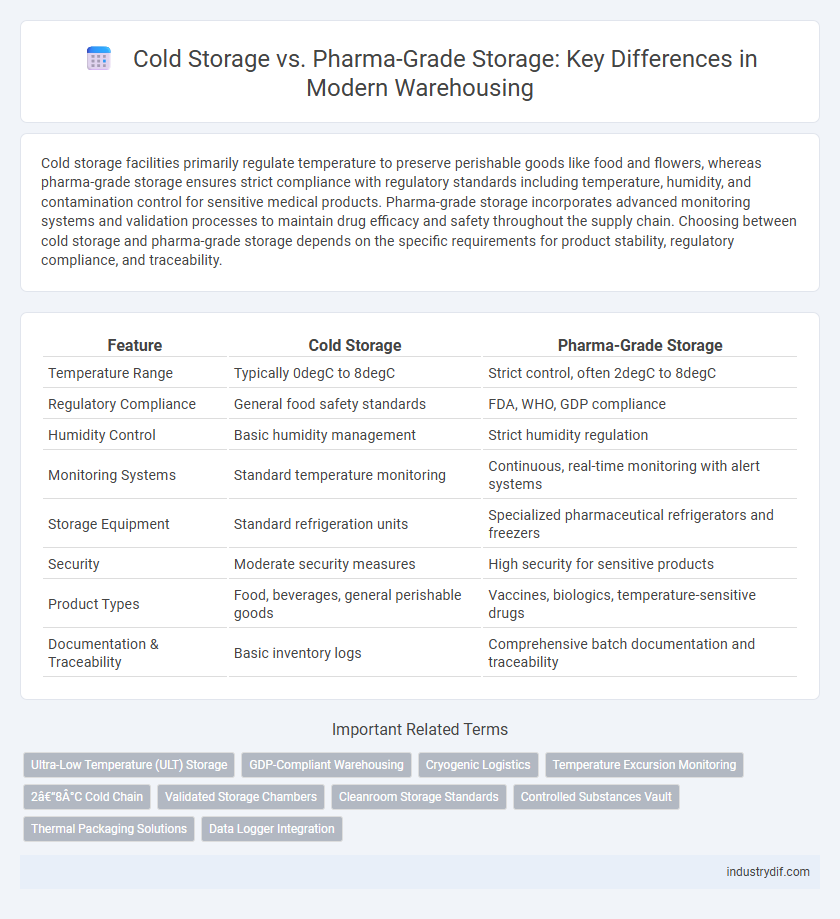

Cold storage facilities primarily regulate temperature to preserve perishable goods like food and flowers, whereas pharma-grade storage ensures strict compliance with regulatory standards including temperature, humidity, and contamination control for sensitive medical products. Pharma-grade storage incorporates advanced monitoring systems and validation processes to maintain drug efficacy and safety throughout the supply chain. Choosing between cold storage and pharma-grade storage depends on the specific requirements for product stability, regulatory compliance, and traceability.

Table of Comparison

| Feature | Cold Storage | Pharma-Grade Storage |

|---|---|---|

| Temperature Range | Typically 0degC to 8degC | Strict control, often 2degC to 8degC |

| Regulatory Compliance | General food safety standards | FDA, WHO, GDP compliance |

| Humidity Control | Basic humidity management | Strict humidity regulation |

| Monitoring Systems | Standard temperature monitoring | Continuous, real-time monitoring with alert systems |

| Storage Equipment | Standard refrigeration units | Specialized pharmaceutical refrigerators and freezers |

| Security | Moderate security measures | High security for sensitive products |

| Product Types | Food, beverages, general perishable goods | Vaccines, biologics, temperature-sensitive drugs |

| Documentation & Traceability | Basic inventory logs | Comprehensive batch documentation and traceability |

Understanding Cold Storage in Warehousing

Cold storage in warehousing refers to temperature-controlled facilities designed to preserve perishable goods such as food, biological samples, and pharmaceuticals by maintaining consistent low temperatures. These warehouses utilize advanced refrigeration systems and insulation technologies to ensure product integrity and prevent spoilage throughout the supply chain. Unlike pharma-grade storage, which requires strict compliance with regulatory standards like GDP (Good Distribution Practice) for drug safety and traceability, cold storage focuses primarily on maintaining optimal temperature ranges for a wide variety of temperature-sensitive items.

Defining Pharma-grade Storage Standards

Pharma-grade storage standards require stringent temperature control, humidity regulation, and contamination prevention to maintain the integrity of sensitive pharmaceutical products. Unlike general cold storage, pharma-grade facilities adhere to Good Distribution Practice (GDP) guidelines, ensuring precise monitoring, qualified equipment, and validated processes. Compliance with regulatory frameworks such as FDA, EMA, and WHO is essential to meet the strict quality and safety criteria for storing vaccines, biologics, and other temperature-sensitive medicines.

Temperature Requirements: Cold Storage vs Pharma-grade

Cold storage facilities typically maintain temperatures between -18degC and 5degC to preserve perishable goods like food and flowers, ensuring product quality and shelf-life. Pharma-grade storage requires more stringent temperature ranges, often between 2degC and 8degC, with tight humidity control and continuous temperature monitoring to comply with regulatory standards for vaccines, biologics, and sensitive medications. Temperature stability and precise environmental control are critical in pharma-grade storage to prevent degradation and maintain drug efficacy.

Compliance and Regulatory Differences

Cold storage facilities are designed to maintain temperature-sensitive products at low temperatures, primarily focusing on general food safety standards like HACCP and FDA cold chain regulations. Pharma-grade storage must comply with stricter regulatory frameworks such as Good Distribution Practices (GDP) and guidelines from regulatory bodies like the FDA, EMA, and WHO, ensuring precise temperature control and traceability for sensitive pharmaceuticals and vaccines. These compliance differences are critical for maintaining product efficacy and meeting legal requirements across cold chain logistics in the pharmaceutical sector.

Infrastructure and Facility Design Comparisons

Cold storage warehouses use insulated walls, advanced refrigeration systems, and controlled humidity to maintain consistent low temperatures ideal for perishable goods. Pharma-grade storage facilities incorporate specialized HVAC systems with HEPA filtration, real-time environmental monitoring, and validated cleanroom standards to ensure aseptic conditions critical for pharmaceuticals. Infrastructure in pharma-grade storage prioritizes contamination control and precise temperature stability, whereas cold storage emphasizes bulk temperature regulation and energy efficiency.

Monitoring and Control Systems

Cold storage warehouses rely on basic temperature and humidity monitoring systems to maintain consistent low temperatures, primarily using standard data loggers and alarms. Pharma-grade storage facilities require advanced, real-time monitoring and control systems with continuous data capture, automated alerts, and compliance with FDA 21 CFR Part 11 for electronic record-keeping and validation. These enhanced systems ensure stringent temperature accuracy, environmental stability, and traceability critical for storing sensitive pharmaceuticals safely.

Inventory Management Practices

Cold storage warehouses require strict temperature controls and humidity monitoring to preserve perishable goods, relying on real-time inventory tracking systems that minimize spoilage and manage expiration dates effectively. Pharma-grade storage facilities incorporate advanced compliance protocols with regulatory standards such as FDA and EMA, using serialization and barcode scanning to ensure traceability and prevent cross-contamination. Both storage types benefit from automated inventory management software that optimizes stock rotation and enhances accuracy in order fulfillment processes.

Risk Management and Contingency Planning

Cold storage warehouses require rigorous temperature controls and monitoring systems to mitigate risks such as spoilage or contamination, essential for perishable goods management. Pharma-grade storage demands even stricter compliance with regulatory standards like GMP and USP, emphasizing risk management through precise environmental controls and validated contingency plans to ensure drug efficacy and patient safety. Effective contingency planning includes backup power systems, real-time monitoring, and emergency response protocols tailored to prevent disruptions in temperature-sensitive inventory handling.

Cost Implications and ROI Analysis

Cold storage facilities typically offer lower initial capital expenditure compared to pharma-grade storage due to less stringent regulatory and environmental control requirements, resulting in reduced operational costs. Pharma-grade storage incurs higher costs driven by advanced temperature monitoring systems, compliance with Good Distribution Practices (GDP), and stringent quality assurance measures, but this investment ensures product integrity and mitigates financial risks associated with spoilage or non-compliance. ROI analysis reveals that while cold storage may yield quicker short-term returns, pharma-grade storage delivers higher long-term value through enhanced product safety, regulatory compliance, and minimized liability costs.

Choosing the Right Storage Solution for Your Products

Cold storage solutions maintain controlled low temperatures ideal for preserving perishable goods, while pharma-grade storage adheres to stringent regulatory standards ensuring stability and efficacy of pharmaceutical products. Selecting the right storage depends on product sensitivity, temperature range, humidity control, and compliance requirements specific to healthcare or food industries. Integrating advanced monitoring systems in both storage types optimizes inventory management, reduces spoilage, and guarantees product integrity throughout the supply chain.

Related Important Terms

Ultra-Low Temperature (ULT) Storage

Ultra-Low Temperature (ULT) Storage in cold storage warehouses maintains temperatures between -40degC and -86degC, essential for preserving biological samples and vaccines with stringent stability requirements. Pharma-grade storage integrates ULT capabilities with compliant monitoring systems, validated clean environments, and regulated access controls to meet strict pharmaceutical industry standards.

GDP-Compliant Warehousing

Cold storage warehouses maintain controlled temperatures essential for preserving a wide range of temperature-sensitive products, but pharma-grade storage specifically adheres to Good Distribution Practice (GDP) standards, ensuring strict environmental monitoring, validated processes, and traceability for pharmaceutical products. GDP-compliant warehousing guarantees integrity and quality during storage and distribution, minimizing risks of contamination, degradation, and ensuring patient safety in the pharmaceutical supply chain.

Cryogenic Logistics

Cryogenic logistics in warehousing demands ultra-low temperature environments, differentiating cold storage, which maintains general refrigeration, from pharma-grade storage designed specifically for temperature-sensitive pharmaceuticals requiring stringent compliance with regulatory standards. Pharma-grade cryogenic storage utilizes advanced insulation and precise temperature monitoring systems to preserve the integrity of biologics, vaccines, and other temperature-sensitive medical products throughout the supply chain.

Temperature Excursion Monitoring

Cold storage facilities require continuous temperature excursion monitoring to maintain the integrity of perishable goods, using advanced sensors to detect deviations from preset temperature ranges. Pharma-grade storage demands even stricter controls with real-time monitoring systems and automated alerts to prevent temperature excursions that could compromise vaccine efficacy and regulatory compliance.

2–8°C Cold Chain

Cold storage facilities maintain a controlled environment strictly between 2-8degC to preserve the integrity of temperature-sensitive pharmaceuticals, ensuring compliance with Good Distribution Practice (GDP) standards and preventing degradation. Pharma-grade storage incorporates advanced monitoring systems and validated processes to guarantee consistent temperature control, minimizing risks in the cold chain and safeguarding vaccine efficacy.

Validated Storage Chambers

Validated storage chambers in pharma-grade storage ensure strict compliance with regulatory standards by maintaining precise temperature, humidity, and contamination controls critical for pharmaceuticals, contrasting with general cold storage that primarily targets consistent low temperatures for perishable goods. The pharmaceutical cold chain's reliance on validated chambers mitigates risks of drug degradation and ensures traceability, which is less emphasized in conventional cold storage solutions.

Cleanroom Storage Standards

Cold storage facilities maintain controlled low temperatures primarily for perishable goods, while pharma-grade storage incorporates stringent cleanroom storage standards including ISO Class 5 to ISO Class 8 environments, ensuring minimal particulate contamination for sensitive pharmaceutical products. Compliance with cleanroom storage standards in pharma-grade warehousing involves advanced HEPA filtration, controlled airflow, and rigorous monitoring of temperature, humidity, and particulate levels to guarantee product integrity and regulatory adherence.

Controlled Substances Vault

Cold storage facilities maintain precise temperature and humidity control ideal for preserving biological samples but lack the stringent security features required for Controlled Substances Vaults in pharma-grade storage. Pharma-grade Controlled Substances Vaults combine temperature regulation with robust access controls, surveillance systems, and compliance with DEA regulations to ensure secure handling and storage of controlled drugs.

Thermal Packaging Solutions

Cold storage facilities maintain consistent low temperatures ideal for preserving general perishable goods, while pharma-grade storage requires stringent temperature controls and validated thermal packaging solutions to ensure drug efficacy and regulatory compliance. Advanced thermal packaging in pharma-grade warehousing utilizes phase change materials and insulated containers to maintain precise thermal conditions during transportation and storage.

Data Logger Integration

Cold storage warehouses utilize data logger integration to continuously monitor temperature and humidity, ensuring compliance with standard preservation requirements. Pharma-grade storage demands advanced data loggers with real-time alerts and audit trails to meet stringent regulatory standards for storing sensitive pharmaceutical products.

Cold Storage vs Pharma-grade Storage Infographic

industrydif.com

industrydif.com