Warehouse Management Systems (WMS) optimize traditional storage and inventory processes by providing real-time data and automation to improve accuracy and efficiency. Micro-fulfillment centers focus on small-scale, high-speed order processing, typically in urban areas, enabling faster delivery by integrating robotics and dense storage solutions. Combining WMS with micro-fulfillment strategies enhances operational agility and meets growing e-commerce demands with reduced fulfillment times and lower transportation costs.

Table of Comparison

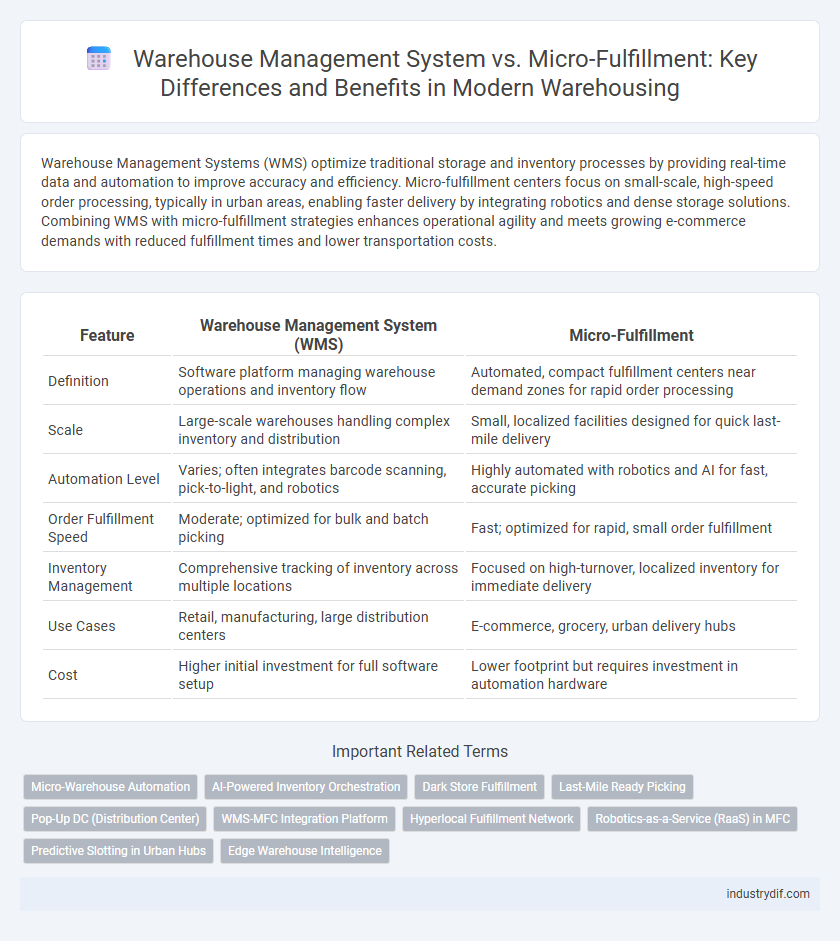

| Feature | Warehouse Management System (WMS) | Micro-Fulfillment |

|---|---|---|

| Definition | Software platform managing warehouse operations and inventory flow | Automated, compact fulfillment centers near demand zones for rapid order processing |

| Scale | Large-scale warehouses handling complex inventory and distribution | Small, localized facilities designed for quick last-mile delivery |

| Automation Level | Varies; often integrates barcode scanning, pick-to-light, and robotics | Highly automated with robotics and AI for fast, accurate picking |

| Order Fulfillment Speed | Moderate; optimized for bulk and batch picking | Fast; optimized for rapid, small order fulfillment |

| Inventory Management | Comprehensive tracking of inventory across multiple locations | Focused on high-turnover, localized inventory for immediate delivery |

| Use Cases | Retail, manufacturing, large distribution centers | E-commerce, grocery, urban delivery hubs |

| Cost | Higher initial investment for full software setup | Lower footprint but requires investment in automation hardware |

Introduction to Warehouse Management Systems

Warehouse Management Systems (WMS) streamline inventory control, improve order accuracy, and enhance operational efficiency by automating key warehouse processes such as receiving, picking, and shipping. Compared to micro-fulfillment centers, which focus on rapid, localized order processing for e-commerce, WMS provides scalable solutions for large warehouses, supporting diverse inventory management and complex supply chain operations. Leading WMS software integrates real-time data analytics and IoT technology to optimize storage space, labor allocation, and inventory turnover rates.

Understanding Micro-Fulfillment Centers

Micro-fulfillment centers (MFCs) optimize warehouse efficiency by automating small-scale inventory storage and rapid order fulfillment, particularly in urban areas. Unlike traditional Warehouse Management Systems (WMS) that oversee large warehouse operations, MFCs leverage robotics and AI to accelerate last-mile delivery and reduce order processing times. Understanding MFCs highlights their role in meeting growing e-commerce demands through compact, technology-driven fulfillment solutions.

Key Features of Warehouse Management Systems

Warehouse Management Systems (WMS) streamline inventory tracking, optimize storage space, and enhance order accuracy through real-time data analytics and automation. Key features include barcode scanning, task prioritization, labor management, and integration with enterprise resource planning (ERP) systems, enabling efficient handling of large-scale warehouse operations. Compared to Micro-Fulfillment Centers, WMS provides comprehensive control over diverse warehouse activities beyond rapid order fulfillment, supporting complex supply chain workflows.

Micro-Fulfillment: Core Components and Technologies

Micro-fulfillment centers rely on advanced automation technologies such as autonomous robots, conveyor systems, and AI-driven inventory management to accelerate order processing and enhance accuracy. Core components include automated storage and retrieval systems (AS/RS), real-time data analytics platforms, and integrated warehouse management software tailored for rapid fulfillment cycles. These technologies enable retailers to optimize space utilization, reduce labor costs, and meet growing consumer demands for faster delivery in e-commerce and omnichannel environments.

Scalability: WMS vs Micro-Fulfillment

Warehouse Management Systems (WMS) offer extensive scalability by integrating with multiple warehouse locations and handling diverse inventory types, enabling smooth expansion for large-scale operations. Micro-fulfillment centers provide scalability through modular units that can be rapidly deployed near urban areas for last-mile delivery but may face limitations in handling high-volume, complex inventories. The choice depends on operational scale and flexibility needs, with WMS suited for broad scalability and micro-fulfillment optimized for localized, high-speed fulfillment.

Inventory Accuracy and Real-Time Tracking

Warehouse Management Systems (WMS) provide robust inventory accuracy through advanced data integration and real-time tracking capabilities, ensuring precise stock levels and location visibility. Micro-fulfillment centers leverage automation and localized storage to enhance order speed and inventory turnover, but their effectiveness relies heavily on the accuracy of incoming data and real-time updates from integrated systems. Combining WMS with micro-fulfillment technology maximizes inventory accuracy and enables seamless real-time tracking critical for meeting modern e-commerce demands.

Integration with E-Commerce Platforms

Warehouse Management Systems (WMS) provide robust integration capabilities with e-commerce platforms, enabling seamless real-time inventory updates, order tracking, and automated fulfillment processes. Micro-fulfillment centers, while highly efficient for rapid last-mile delivery, often require specialized integration layers to connect with diverse online storefronts and marketplaces. Optimizing the synchronization between WMS and e-commerce platforms enhances operational efficiency and improves customer satisfaction through accurate order processing and faster delivery times.

Cost Efficiency and ROI Analysis

Warehouse Management Systems (WMS) optimize inventory control and labor productivity, reducing operational costs through streamlined processes and real-time data analytics. Micro-fulfillment centers, leveraging automation and proximity to end consumers, minimize last-mile delivery expenses and accelerate order fulfillment, enhancing overall cost efficiency. ROI analysis reveals that while WMS investments yield long-term savings in large-scale operations, micro-fulfillment solutions provide faster payback periods in urban and high-demand markets due to lower transportation and labor costs.

Case Studies: WMS vs Micro-Fulfillment Applications

Case studies reveal that Warehouse Management Systems (WMS) enhance inventory accuracy and streamline order fulfillment in large-scale distribution centers, leveraging real-time data for optimized storage and labor utilization. Micro-fulfillment solutions excel in urban retail environments by enabling rapid, automated order processing through compact, robotic systems, significantly reducing last-mile delivery times. Comparative analyses demonstrate that integrating WMS with micro-fulfillment technologies yields hybrid models that optimize both high-volume throughput and speedy localized deliveries.

Future Trends in Warehouse Automation

Warehouse Management Systems (WMS) integrate AI-driven analytics and IoT sensors to optimize inventory accuracy and streamline order processing at scale. Micro-fulfillment centers leverage robotics and localized automation to enhance last-mile delivery speed and reduce operational costs in urban environments. Future trends emphasize hybrid models combining WMS frameworks with micro-fulfillment technologies, driving real-time data synchronization and adaptive automation to meet evolving consumer demands.

Related Important Terms

Micro-Warehouse Automation

Micro-warehouse automation leverages advanced robotics, AI-driven sorting, and real-time inventory tracking to optimize space utilization and expedite order fulfillment within compact facilities, surpassing traditional Warehouse Management Systems (WMS) in agility and efficiency. Integrating micro-fulfillment centers with automated systems reduces labor costs and delivery times, meeting rising consumer demand for fast and accurate order processing in urban retail environments.

AI-Powered Inventory Orchestration

AI-powered inventory orchestration in Warehouse Management Systems (WMS) enhances real-time stock accuracy, demand forecasting, and automated replenishment, reducing operational costs and errors. Micro-fulfillment centers leverage AI to optimize compact storage layouts and accelerate order processing, enabling faster delivery times within urban environments.

Dark Store Fulfillment

Warehouse Management Systems (WMS) optimize inventory control, order processing, and labor management within large-scale warehouses, enhancing operational efficiency and accuracy. Micro-fulfillment strategies, particularly using dark store fulfillment models, prioritize rapid, localized order processing by transforming small urban spaces into mini-warehouses, enabling faster last-mile delivery and meeting rising e-commerce demands.

Last-Mile Ready Picking

Warehouse Management Systems (WMS) streamline inventory control and order processing, while micro-fulfillment centers specialize in rapid, last-mile ready picking by positioning goods closer to the end consumer. Integrating micro-fulfillment strategies within WMS enhances efficiency in urban logistics, reducing delivery times and boosting customer satisfaction.

Pop-Up DC (Distribution Center)

A Warehouse Management System (WMS) optimizes inventory control and order fulfillment processes within traditional distribution centers, while micro-fulfillment centers focus on localized, rapid order processing in small-scale Pop-Up DCs to meet increasing urban demand. Pop-Up DCs leverage micro-fulfillment technology to enhance last-mile delivery speed, reduce operational costs, and enable agile inventory deployment in high-density markets.

WMS-MFC Integration Platform

Warehouse Management System (WMS) integration with Micro-Fulfillment Centers (MFC) optimizes inventory accuracy, order processing speed, and spatial efficiency by synchronizing data across automated picking technologies and real-time inventory tracking. This integrated platform enables scalable operations, reduces labor costs, and enhances fulfillment agility by leveraging advanced robotics, AI-driven analytics, and seamless inventory visibility within urban, high-density logistics environments.

Hyperlocal Fulfillment Network

Warehouse Management Systems (WMS) optimize inventory control and operational efficiency within centralized warehouses, while micro-fulfillment centers enable rapid, hyperlocal fulfillment by strategically positioning goods near end customers. Hyperlocal fulfillment networks leverage micro-fulfillment technology to reduce last-mile delivery times and boost customer satisfaction through localized inventory management integrated with WMS for seamless order processing.

Robotics-as-a-Service (RaaS) in MFC

Warehouse Management Systems (WMS) provide software solutions to optimize inventory control and order processing, while Micro-Fulfillment Centers (MFC) leverage Robotics-as-a-Service (RaaS) to automate small-scale, high-speed order fulfillment directly within urban or retail environments. RaaS in MFCs enhances operational efficiency by offering scalable robotic automation without heavy upfront investment, enabling rapid response to fluctuating demand and reducing labor costs.

Predictive Slotting in Urban Hubs

Predictive slotting in urban hubs leverages advanced Warehouse Management Systems (WMS) to optimize inventory placement based on real-time data and demand forecasting, enhancing picking efficiency and reducing fulfillment times. Micro-fulfillment centers integrate these predictive algorithms to adapt dynamically to high-density urban demands, enabling faster order processing and minimizing last-mile delivery challenges.

Edge Warehouse Intelligence

Warehouse Management System (WMS) integrates inventory control and order processing, optimizing large-scale warehouse operations, while Micro-Fulfillment leverages Edge Warehouse Intelligence to enable real-time data processing at the facility level, enhancing speed and accuracy for urban last-mile delivery. Edge computing in micro-fulfillment centers empowers autonomous robotics and AI-driven decision-making, reducing latency and operational costs compared to traditional centralized WMS infrastructures.

Warehouse Management System vs Micro-Fulfillment Infographic

industrydif.com

industrydif.com