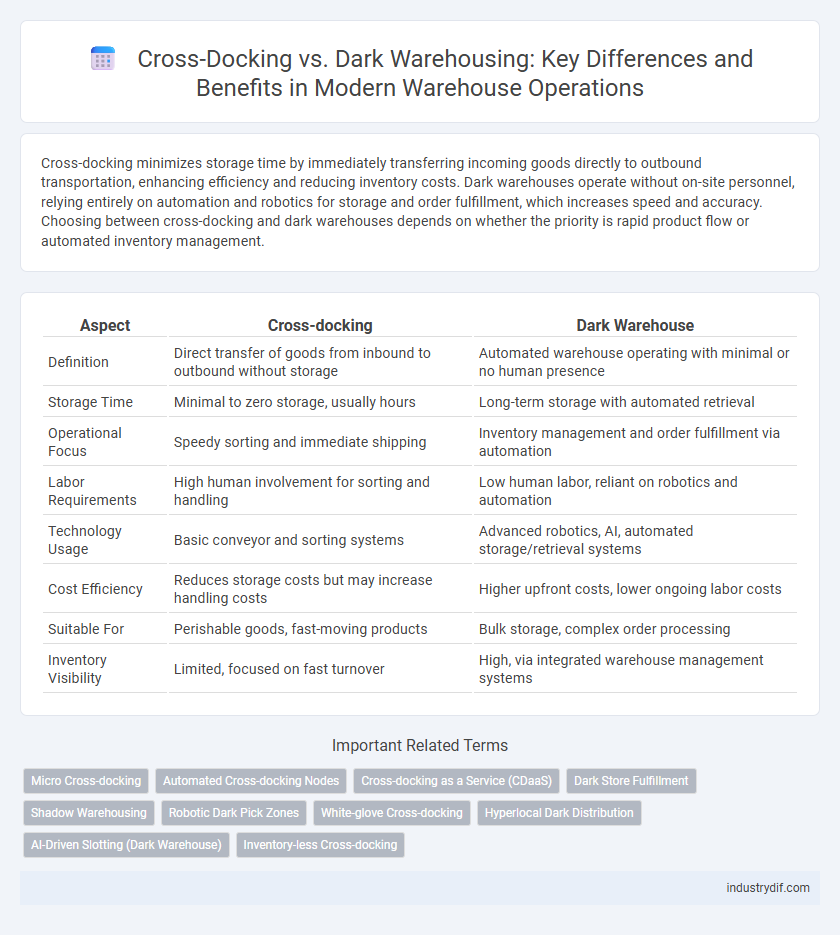

Cross-docking minimizes storage time by immediately transferring incoming goods directly to outbound transportation, enhancing efficiency and reducing inventory costs. Dark warehouses operate without on-site personnel, relying entirely on automation and robotics for storage and order fulfillment, which increases speed and accuracy. Choosing between cross-docking and dark warehouses depends on whether the priority is rapid product flow or automated inventory management.

Table of Comparison

| Aspect | Cross-docking | Dark Warehouse |

|---|---|---|

| Definition | Direct transfer of goods from inbound to outbound without storage | Automated warehouse operating with minimal or no human presence |

| Storage Time | Minimal to zero storage, usually hours | Long-term storage with automated retrieval |

| Operational Focus | Speedy sorting and immediate shipping | Inventory management and order fulfillment via automation |

| Labor Requirements | High human involvement for sorting and handling | Low human labor, reliant on robotics and automation |

| Technology Usage | Basic conveyor and sorting systems | Advanced robotics, AI, automated storage/retrieval systems |

| Cost Efficiency | Reduces storage costs but may increase handling costs | Higher upfront costs, lower ongoing labor costs |

| Suitable For | Perishable goods, fast-moving products | Bulk storage, complex order processing |

| Inventory Visibility | Limited, focused on fast turnover | High, via integrated warehouse management systems |

Introduction to Cross-docking and Dark Warehousing

Cross-docking is a logistics practice where incoming shipments are directly transferred to outbound vehicles with minimal storage time, reducing inventory holding costs and speeding up order fulfillment. Dark warehousing, in contrast, refers to fully automated warehouses that operate without on-site staff, utilizing robotics and AI for inventory management and order processing. Both strategies optimize supply chain efficiency but differ in operational approaches and technology usage.

Key Definitions: Cross-docking and Dark Warehouse

Cross-docking is a logistics process where incoming shipments are directly transferred from inbound to outbound transportation with minimal or no storage time, enhancing supply chain efficiency. Dark warehouses operate without on-site human presence, relying on automation and robotics to manage inventory storage and retrieval in a fully autonomous environment. Both strategies optimize warehousing by reducing handling time and labor costs but differ fundamentally in operational execution and technological integration.

Operational Workflow Comparison

Cross-docking streamlines operational workflow by directly transferring inbound goods to outbound transportation with minimal storage, reducing handling time and inventory holding costs. Dark warehouses operate with fully automated systems and no on-site staff, optimizing storage density and order fulfillment through robotics and AI-driven inventory management. While cross-docking prioritizes speed and efficiency in distribution, dark warehouses emphasize automation and space utilization for scalable, cost-effective warehousing.

Technology Requirements in Both Methods

Cross-docking requires advanced real-time tracking systems, automated sorting technologies, and integrated transportation management software to ensure rapid transfer and minimal storage time. Dark warehouses depend heavily on automation, such as robotics and AI-driven inventory management, to operate efficiently without on-site personnel. Both methods leverage IoT sensors and data analytics to optimize workflow, but cross-docking emphasizes speed and coordination, while dark warehouses prioritize automation and remote control.

Inventory Management Strategies

Cross-docking minimizes inventory holding by transferring goods directly from inbound to outbound transportation, enhancing throughput and reducing storage costs. Dark warehouses operate without on-site staff, relying heavily on automation and precise inventory tracking systems to optimize storage efficiency and order fulfillment. Effective inventory management strategies for cross-docking emphasize rapid turnover and minimal stock levels, while dark warehouses focus on real-time visibility and automated replenishment to maintain accuracy and reduce errors.

Cost Implications and ROI Analysis

Cross-docking minimizes inventory holding costs by facilitating direct product transfer from inbound to outbound transportation, leading to faster turnaround times and reduced storage fees. Dark warehouses, though requiring higher initial capital investment due to automation and labor expenses, offer cost savings over time through enhanced operational efficiency and scalability. ROI analysis reveals cross-docking provides quicker returns in high-turnover scenarios, while dark warehouses deliver long-term profitability in markets demanding complex inventory management.

Impact on Supply Chain Efficiency

Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation, significantly reducing handling costs and accelerating order fulfillment. Dark warehouses, operating without on-site staff and relying heavily on automation, optimize space utilization and reduce labor expenses but may introduce delays due to complex robotic sorting systems. Both strategies enhance supply chain efficiency through improved inventory flow, with cross-docking excelling in speed and dark warehouses in cost-effective, scalable storage solutions.

Scalability and Flexibility Factors

Cross-docking enhances scalability by enabling rapid throughput of goods without long-term storage, reducing inventory holding costs and improving supply chain responsiveness. Dark warehouses offer flexibility through automation and reduced labor costs but may face limitations in scaling quickly due to fixed infrastructure and high initial investment. Businesses prioritize cross-docking for dynamic demand environments, while dark warehouses suit stable, predictable inventory flows with a focus on operational efficiency.

Risks and Challenges in Implementation

Cross-docking faces challenges such as tight scheduling requirements, potential delays in inbound shipments, and the need for precise inventory coordination, increasing the risk of operational bottlenecks. Dark warehouses, while reducing labor costs through automation, present risks including high capital expenditure, technology dependence, and complex system integration, which can lead to implementation delays and costly errors. Both models demand robust IT infrastructure and real-time data accuracy to mitigate risks related to inventory mismanagement and supply chain disruptions.

Choosing the Right Solution for Your Business

Choosing between cross-docking and dark warehouses depends on your business's operational goals and inventory turnover rates. Cross-docking optimizes speed by minimizing storage time, ideal for high-volume, fast-moving products, while dark warehouses reduce labor costs through automation, perfect for e-commerce businesses with fluctuating order sizes. Evaluate your supply chain complexity, order frequency, and technology investment capacity to determine the most efficient warehousing solution.

Related Important Terms

Micro Cross-docking

Micro cross-docking streamlines inventory flow by transferring goods directly from inbound to outbound transportation with minimal storage, enhancing efficiency compared to traditional warehousing models like dark warehouses, which focus on holding stock without active processing. This approach reduces handling time, lowers storage costs, and increases order fulfillment speed, making it increasingly vital in modern supply chain management.

Automated Cross-docking Nodes

Automated cross-docking nodes streamline supply chain efficiency by minimizing storage time and accelerating product flow directly from inbound to outbound transportation, contrasting with dark warehouses that prioritize inventory holding without active processing. These nodes deploy advanced robotics and real-time data analytics to optimize sorting, reduce labor costs, and increase throughput, enabling just-in-time delivery in high-demand distribution networks.

Cross-docking as a Service (CDaaS)

Cross-docking as a Service (CDaaS) streamlines supply chain efficiency by enabling rapid transfer of goods directly from inbound to outbound transportation with minimal storage time, reducing inventory holding costs and accelerating order fulfillment. Unlike dark warehouses that operate without onsite staff, CDaaS leverages integrated technology and expert logistics management to optimize real-time product flow and improve delivery speed.

Dark Store Fulfillment

Dark store fulfillment optimizes order processing by using specialized warehouses that serve exclusively as fulfillment centers without customer-facing operations, significantly reducing handling time and increasing efficiency. Unlike cross-docking, which transfers goods directly from inbound to outbound shipments, dark stores allow for precise inventory management and rapid order picking tailored to e-commerce demands.

Shadow Warehousing

Shadow warehousing, a form of dark warehousing, enables retailers to store excess inventory offsite without customer access, improving supply chain flexibility and reducing congestion in primary warehouses. Unlike cross-docking, which minimizes storage time by transferring goods directly from inbound to outbound transport, shadow warehouses prioritize inventory holding and demand buffering in a concealed, cost-effective environment.

Robotic Dark Pick Zones

Robotic Dark Pick Zones in warehousing leverage autonomous systems to efficiently handle inventory without human intervention, contrasting with cross-docking that prioritizes rapid transfer of goods between incoming and outgoing shipments to minimize storage time. These automated zones optimize order fulfillment by enabling dark warehouses to operate 24/7 with high accuracy and reduced labor costs, enhancing overall supply chain efficiency.

White-glove Cross-docking

White-glove cross-docking enhances warehousing efficiency by providing specialized handling, immediate order fulfillment, and minimal storage time, contrasting with dark warehouses that rely on automated, low-touch inventory management without direct customer interaction. This approach optimizes supply chain speed and accuracy for high-value or fragile goods requiring premium service levels.

Hyperlocal Dark Distribution

Hyperlocal dark distribution leverages dark warehouses to streamline last-mile delivery by minimizing inventory handling and storage time, enhancing rapid fulfillment within localized zones. Cross-docking complements this approach by enabling direct transfer of goods from inbound to outbound transportation, reducing warehousing costs and accelerating order processing in densely populated urban areas.

AI-Driven Slotting (Dark Warehouse)

AI-driven slotting in dark warehouses leverages advanced machine learning algorithms to optimize inventory placement, maximizing space utilization and minimizing retrieval times. This technology contrasts with traditional cross-docking by enabling real-time inventory management and predictive analytics within highly automated, unmanned storage facilities.

Inventory-less Cross-docking

Inventory-less cross-docking eliminates storage by directly transferring incoming shipments to outbound transportation, reducing handling time and storage costs compared to traditional warehouses. Dark warehouses operate without onsite staff, relying on automated systems for inventory management but still require storage, making them less efficient than inventory-less cross-docking for rapid order fulfillment.

Cross-docking vs Dark warehouse Infographic

industrydif.com

industrydif.com