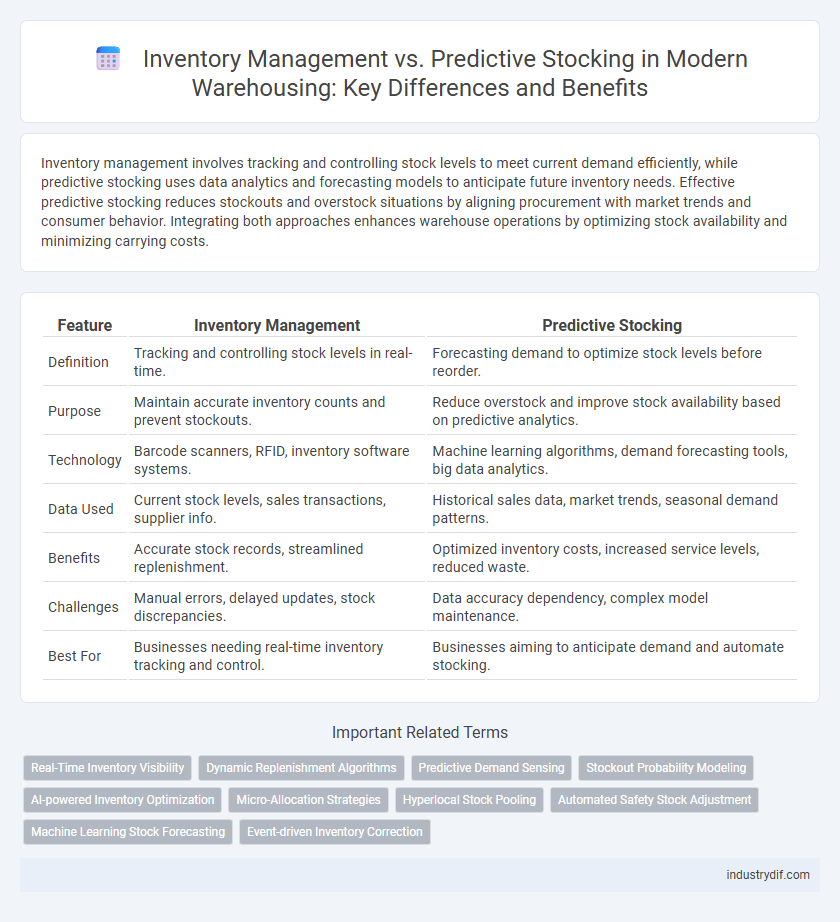

Inventory management involves tracking and controlling stock levels to meet current demand efficiently, while predictive stocking uses data analytics and forecasting models to anticipate future inventory needs. Effective predictive stocking reduces stockouts and overstock situations by aligning procurement with market trends and consumer behavior. Integrating both approaches enhances warehouse operations by optimizing stock availability and minimizing carrying costs.

Table of Comparison

| Feature | Inventory Management | Predictive Stocking |

|---|---|---|

| Definition | Tracking and controlling stock levels in real-time. | Forecasting demand to optimize stock levels before reorder. |

| Purpose | Maintain accurate inventory counts and prevent stockouts. | Reduce overstock and improve stock availability based on predictive analytics. |

| Technology | Barcode scanners, RFID, inventory software systems. | Machine learning algorithms, demand forecasting tools, big data analytics. |

| Data Used | Current stock levels, sales transactions, supplier info. | Historical sales data, market trends, seasonal demand patterns. |

| Benefits | Accurate stock records, streamlined replenishment. | Optimized inventory costs, increased service levels, reduced waste. |

| Challenges | Manual errors, delayed updates, stock discrepancies. | Data accuracy dependency, complex model maintenance. |

| Best For | Businesses needing real-time inventory tracking and control. | Businesses aiming to anticipate demand and automate stocking. |

Introduction to Inventory Management and Predictive Stocking

Inventory management involves systematically tracking and controlling stock levels to ensure sufficient supply while minimizing holding costs. Predictive stocking leverages advanced analytics and historical sales data to forecast demand, enabling proactive inventory replenishment. Integrating predictive stocking with traditional inventory management enhances accuracy in meeting customer demand and reduces stockouts and overstock situations.

Core Principles of Inventory Management

Inventory management centers on accurately tracking stock levels, setting reorder points, and maintaining optimal quantities to prevent stockouts and overstocking. It relies on real-time data analysis and systematic categorization techniques such as ABC analysis to prioritize high-value items. Predictive stocking enhances these principles by using machine learning algorithms to forecast demand patterns, enabling proactive replenishment and minimizing holding costs.

What Is Predictive Stocking?

Predictive stocking uses advanced algorithms and historical sales data to forecast future inventory needs, minimizing stockouts and overstock situations. By analyzing patterns such as seasonal demand fluctuations, customer purchasing behavior, and lead times, it enables warehouses to optimize stock levels proactively. This data-driven approach improves inventory turnover rates and reduces carrying costs compared to traditional inventory management methods.

Key Differences Between Inventory Management and Predictive Stocking

Inventory management primarily tracks and controls current stock levels, ensuring accurate records and efficient order fulfillment, whereas predictive stocking uses data analytics and demand forecasting to anticipate future inventory needs and optimize stock replenishment. Inventory management focuses on maintaining accuracy and minimizing overstock or stockouts in real-time, while predictive stocking leverages historical sales data, market trends, and seasonality to proactively adjust stock levels before demand changes occur. The key difference lies in reactive control versus proactive strategy, with predictive stocking enhancing supply chain responsiveness and reducing holding costs through advanced forecasting models.

Technologies Powering Predictive Stocking

Predictive stocking leverages advanced technologies such as machine learning algorithms, IoT sensors, and big data analytics to forecast demand with high accuracy and optimize inventory levels. These tools analyze historical sales data, real-time market trends, and external factors like seasonality or supply chain disruptions to minimize stockouts and overstock situations. Compared to traditional inventory management systems, predictive stocking enables dynamic replenishment strategies that reduce carrying costs and improve overall warehouse efficiency.

Benefits of Traditional Inventory Management

Traditional inventory management ensures accurate stock tracking and real-time visibility, reducing stockouts and overstock situations. It simplifies order processing and enhances supplier coordination through established procedures and manual oversight. This method supports cost control by maintaining optimal inventory levels and minimizing holding costs without relying on complex algorithms.

Advantages of Predictive Stocking in Modern Warehousing

Predictive stocking leverages advanced analytics and machine learning to accurately forecast demand, reducing overstock and stockouts in modern warehousing. This approach enhances inventory turnover rates by aligning stock levels with real-time consumer behavior and market trends. By minimizing excess inventory, predictive stocking lowers storage costs and improves overall supply chain efficiency.

Common Challenges and Pitfalls

Inventory management often struggles with stock inaccuracies and inefficient reorder points, leading to overstocking or stockouts that increase holding costs and reduce customer satisfaction. Predictive stocking faces challenges in data quality and algorithm reliability, which can result in inaccurate demand forecasts and misaligned stock levels. Both approaches require continuous data integration and technology upgrades to avoid pitfalls such as inventory obsolescence and lost sales opportunities.

Industry Use Cases: Inventory Management vs Predictive Stocking

Inventory management systems streamline warehouse operations by tracking current stock levels, order status, and shipment details to ensure optimal storage and timely replenishment. Predictive stocking leverages advanced algorithms and historical sales data to forecast demand, reducing stockouts and overstock scenarios in industries like retail, manufacturing, and e-commerce. Companies using predictive stocking benefit from improved cash flow, enhanced customer satisfaction, and minimized waste compared to traditional inventory management approaches.

Future Trends in Warehousing Optimization

Inventory management systems continuously track stock levels and reorder points to maintain operational efficiency, while predictive stocking leverages AI and machine learning algorithms to forecast demand with higher accuracy. Future trends in warehousing optimization emphasize integrating predictive analytics to minimize stockouts and overstock, thereby reducing carrying costs and enhancing customer satisfaction. Automation technologies combined with real-time data analysis are set to revolutionize inventory strategies, enabling warehouses to respond swiftly to market changes.

Related Important Terms

Real-Time Inventory Visibility

Real-time inventory visibility enhances inventory management by providing instant data on stock levels, enabling accurate order fulfillment and reducing stockouts. Predictive stocking leverages this live inventory data with advanced analytics to forecast demand, optimizing stock replenishment and minimizing excess inventory.

Dynamic Replenishment Algorithms

Dynamic replenishment algorithms optimize inventory management by analyzing real-time sales data and demand patterns to adjust stock levels accurately. These algorithms enhance predictive stocking by minimizing overstock and stockouts, improving warehouse efficiency and reducing carrying costs.

Predictive Demand Sensing

Predictive demand sensing leverages real-time data and advanced analytics to anticipate inventory needs, reducing stockouts and excess inventory in warehousing operations. This approach surpasses traditional inventory management by dynamically adjusting stock levels based on short-term demand signals and market fluctuations.

Stockout Probability Modeling

Inventory management traditionally relies on historical sales data to maintain stock levels, whereas predictive stocking utilizes stockout probability modeling to forecast potential inventory shortages and optimize reorder points. This approach leverages advanced analytics and machine learning algorithms to minimize stockouts, reduce holding costs, and improve supply chain efficiency.

AI-powered Inventory Optimization

AI-powered inventory optimization integrates inventory management with predictive stocking by leveraging machine learning algorithms to analyze historical sales data, seasonal trends, and demand fluctuations, enabling precise stock level adjustments that reduce overstock and prevent stockouts. This advanced approach enhances supply chain efficiency, minimizes carrying costs, and improves fulfillment rates by forecasting future inventory needs with higher accuracy than traditional methods.

Micro-Allocation Strategies

Inventory management relies on tracking stock levels and replenishment cycles to maintain optimal warehouse operations, while predictive stocking uses data analytics and machine learning to forecast demand and proactively allocate inventory. Micro-allocation strategies enhance both approaches by segmenting stock at a granular level, optimizing space utilization, reducing holding costs, and improving order fulfillment accuracy.

Hyperlocal Stock Pooling

Inventory management ensures accurate tracking and replenishment of stock levels to meet demand, while predictive stocking leverages data analytics and machine learning to forecast demand and optimize stock placement. Hyperlocal stock pooling enhances these strategies by aggregating inventory across multiple nearby warehouses, reducing delivery times and improving fulfillment efficiency in localized areas.

Automated Safety Stock Adjustment

Automated safety stock adjustment leverages real-time data analytics and machine learning algorithms to dynamically optimize inventory levels, reducing excess stock and stockouts. This predictive stocking approach enhances traditional inventory management by forecasting demand fluctuations and adjusting safety stock accordingly, improving overall warehousing efficiency.

Machine Learning Stock Forecasting

Machine learning stock forecasting enhances inventory management by analyzing historical sales data and market trends to predict optimal stock levels, reducing overstock and stockouts. This predictive stocking approach leverages algorithms to dynamically adjust inventory in real-time, improving warehouse efficiency and customer satisfaction.

Event-driven Inventory Correction

Event-driven inventory correction enhances accuracy by automatically updating stock levels in real-time based on events such as sales, returns, or shipments, reducing discrepancies common in traditional inventory management. Predictive stocking leverages this dynamic data, analyzing patterns to forecast demand and optimize reorder points, minimizing stockouts and excess inventory.

Inventory Management vs Predictive Stocking Infographic

industrydif.com

industrydif.com