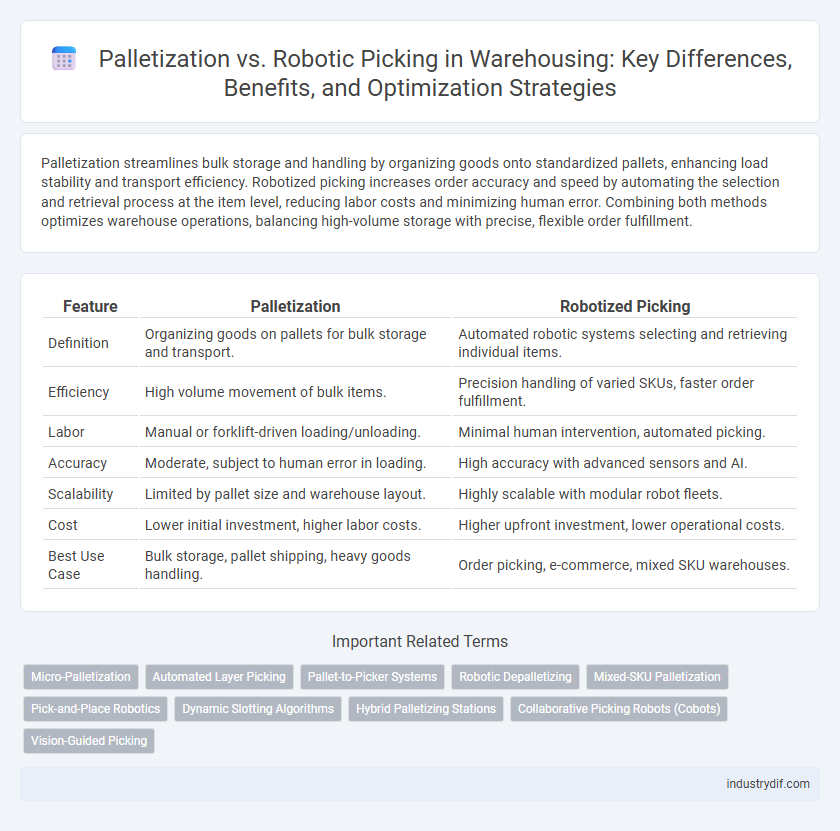

Palletization streamlines bulk storage and handling by organizing goods onto standardized pallets, enhancing load stability and transport efficiency. Robotized picking increases order accuracy and speed by automating the selection and retrieval process at the item level, reducing labor costs and minimizing human error. Combining both methods optimizes warehouse operations, balancing high-volume storage with precise, flexible order fulfillment.

Table of Comparison

| Feature | Palletization | Robotized Picking |

|---|---|---|

| Definition | Organizing goods on pallets for bulk storage and transport. | Automated robotic systems selecting and retrieving individual items. |

| Efficiency | High volume movement of bulk items. | Precision handling of varied SKUs, faster order fulfillment. |

| Labor | Manual or forklift-driven loading/unloading. | Minimal human intervention, automated picking. |

| Accuracy | Moderate, subject to human error in loading. | High accuracy with advanced sensors and AI. |

| Scalability | Limited by pallet size and warehouse layout. | Highly scalable with modular robot fleets. |

| Cost | Lower initial investment, higher labor costs. | Higher upfront investment, lower operational costs. |

| Best Use Case | Bulk storage, pallet shipping, heavy goods handling. | Order picking, e-commerce, mixed SKU warehouses. |

Introduction to Palletization and Robotized Picking

Palletization streamlines warehouse operations by organizing goods onto pallets for efficient storage and transportation, maximizing space utilization and reducing handling time. Robotized picking employs automated systems with robotic arms or autonomous vehicles to accurately retrieve individual items, enhancing order fulfillment speed and minimizing errors. Both technologies improve logistics efficiency but cater to different operational needs based on order volume and warehouse complexity.

Key Differences Between Palletization and Robotized Picking

Palletization organizes goods onto pallets for efficient bulk transport and storage, optimizing space and handling in warehouses. Robotized picking utilizes automated robots to select and retrieve individual items directly from shelves, enhancing precision and speed in order fulfillment. Key differences lie in palletization's focus on bulk movement versus robotized picking's emphasis on item-level accuracy and flexibility in complex environments.

Core Technologies Driving Palletization

Core technologies driving palletization include automated stacking systems, conveyor belts, and robotic arms equipped with advanced sensors that ensure precise item placement. Machine learning algorithms optimize load distribution for enhanced space utilization and stability during transport. Integration of IoT devices enables real-time monitoring and analytics, improving efficiency and reducing errors in warehouse operations.

Innovations in Robotized Picking Systems

Robotized picking systems incorporate advanced algorithms and AI-powered vision technology to enhance accuracy and efficiency in order fulfillment. Innovations such as collaborative robots (cobots) and automated guided vehicles (AGVs) minimize human intervention while optimizing space utilization and throughput. Integration with warehouse management systems (WMS) enables real-time inventory tracking and adaptive task allocation, surpassing traditional palletization in speed and flexibility.

Benefits of Palletization in Modern Warehousing

Palletization enhances warehouse efficiency by facilitating faster handling and transportation of bulk goods, reducing manual labor requirements and minimizing product damage during movement. Standardized pallet sizes streamline storage space optimization and improve compatibility with automated systems, increasing overall operational throughput. This method supports better inventory management through easier tracking and organization, leading to reduced order fulfillment times and lower operational costs.

Advantages of Robotized Picking for Order Fulfillment

Robotized picking enhances order fulfillment by significantly increasing accuracy and reducing human error, leading to fewer shipment mistakes and higher customer satisfaction. Automated systems enable faster processing speeds and continuous operation, which optimize warehouse throughput and reduce labor costs. Integration with warehouse management software allows real-time inventory tracking and efficient order prioritization, improving overall supply chain responsiveness.

Challenges Faced in Palletization vs Robotized Picking

Palletization faces challenges such as limited flexibility and difficulties in handling irregularly shaped or fragile items, which can lead to increased damage rates and inefficiencies. Robotized picking encounters issues related to complex algorithm development, high initial investment costs, and integration with existing warehouse management systems, affecting scalability and ROI. Both methods require careful consideration of the warehouse layout and product variability to optimize operations and minimize errors.

Cost and ROI Comparison: Palletization vs Robotized Picking

Palletization offers lower initial investment costs and faster ROI for warehouses handling bulk, standardized products, optimizing space with minimal technology integration. Robotized picking demands higher upfront capital but enhances labor efficiency, reduces human error, and accelerates order fulfillment, leading to greater long-term savings and scalability. Decision-making hinges on order complexity, volume, and growth projections to balance cost against return on investment effectively.

Scalability and Flexibility in Warehousing Operations

Palletization offers high scalability by enabling bulk handling of standardized loads, ideal for warehouses with consistent product types and volumes. Robotized picking enhances flexibility by adapting to diverse SKUs and varying order profiles, allowing rapid reconfiguration for seasonal or promotional shifts. Combining both approaches can optimize operational efficiency, balancing scalable throughput with the agility required for dynamic inventory demands.

Future Trends: Integrating Palletization and Robotized Picking

Future trends in warehousing emphasize the integration of palletization and robotized picking to enhance operational efficiency and accuracy. Combining automated palletizing systems with advanced robotic picking technologies enables seamless material handling, reducing human error and labor costs while speeding up order fulfillment. IoT-enabled sensors and AI-driven analytics further support real-time coordination between pallet stacking and robotic retrieval, driving the evolution of smart warehouses.

Related Important Terms

Micro-Palletization

Micro-palletization enhances warehouse efficiency by optimizing space utilization and enabling faster, more precise robotized picking operations compared to traditional palletization methods. This approach reduces labor costs and minimizes handling errors through automated, high-density storage configurations suited for small to medium-sized items.

Automated Layer Picking

Automated layer picking enhances warehouse efficiency by using robotics to handle entire pallet layers, significantly reducing manual labor and increasing throughput compared to traditional palletization methods. This technology integrates advanced sensors and AI-driven systems to optimize picking accuracy, inventory management, and order fulfillment speed in highly automated warehouses.

Pallet-to-Picker Systems

Pallet-to-Picker systems streamline warehousing by delivering entire pallets directly to pickers, significantly reducing travel time and increasing order fulfillment speed compared to traditional palletization methods. Enhanced with automation and integrated robotics, these systems optimize space utilization and improve accuracy in high-volume distribution centers.

Robotic Depalletizing

Robotic depalletizing enhances warehousing efficiency by automating the unloading of goods from pallets, reducing labor costs and minimizing product damage compared to manual palletization methods. Advanced robotic systems equipped with vision technology enable precise and rapid handling of diverse packaging types, streamlining inventory management and accelerating order fulfillment.

Mixed-SKU Palletization

Mixed-SKU palletization increases efficiency in warehousing by grouping various products on a single pallet, reducing shipping costs and optimizing storage space. Robotized picking complements this by automating the selection process, improving accuracy and throughput in handling diverse inventory.

Pick-and-Place Robotics

Pick-and-place robotics in warehousing significantly enhances efficiency by automating the palletization process, reducing human error and increasing throughput speed for stacking and organizing goods. Compared to robotized picking systems that focus on selecting individual items, palletization robots excel in handling bulk loads, optimizing space utilization and streamlining loading operations for transportation and storage.

Dynamic Slotting Algorithms

Dynamic slotting algorithms enhance palletization by optimizing storage locations based on product velocity and size, significantly improving space utilization and retrieval efficiency. In robotized picking, these algorithms adapt in real-time to order patterns and inventory changes, enabling faster pick cycles and reduced labor costs.

Hybrid Palletizing Stations

Hybrid palletizing stations combine the efficiency of robotic picking with traditional palletization methods, optimizing space utilization and throughput in warehousing operations. These systems enhance flexibility by enabling simultaneous handling of diverse product sizes and weights, reducing downtime and improving overall supply chain productivity.

Collaborative Picking Robots (Cobots)

Collaborative picking robots (cobots) enhance warehouse efficiency by combining the precision of robotized picking with human oversight, optimizing order accuracy and reducing labor costs compared to traditional palletization methods. These cobots adapt to dynamic environments, working safely alongside workers to increase throughput and streamline inventory management.

Vision-Guided Picking

Vision-guided picking enhances robotized picking by enabling automated systems to accurately identify, locate, and handle items, improving efficiency and reducing errors compared to traditional palletization methods. This advanced technology leverages machine vision to optimize inventory management and streamline order fulfillment in modern warehouses.

Palletization vs Robotized Picking Infographic

industrydif.com

industrydif.com