Cranes are essential for lifting and moving heavy materials on construction sites, but robotic cranes offer enhanced precision and automation, reducing human error and increasing efficiency. Robotic cranes integrate advanced sensors and AI technology to perform complex tasks with minimal supervision, improving safety and productivity. While traditional cranes rely heavily on skilled operators, robotic cranes streamline operations and provide consistent, reliable performance in challenging environments.

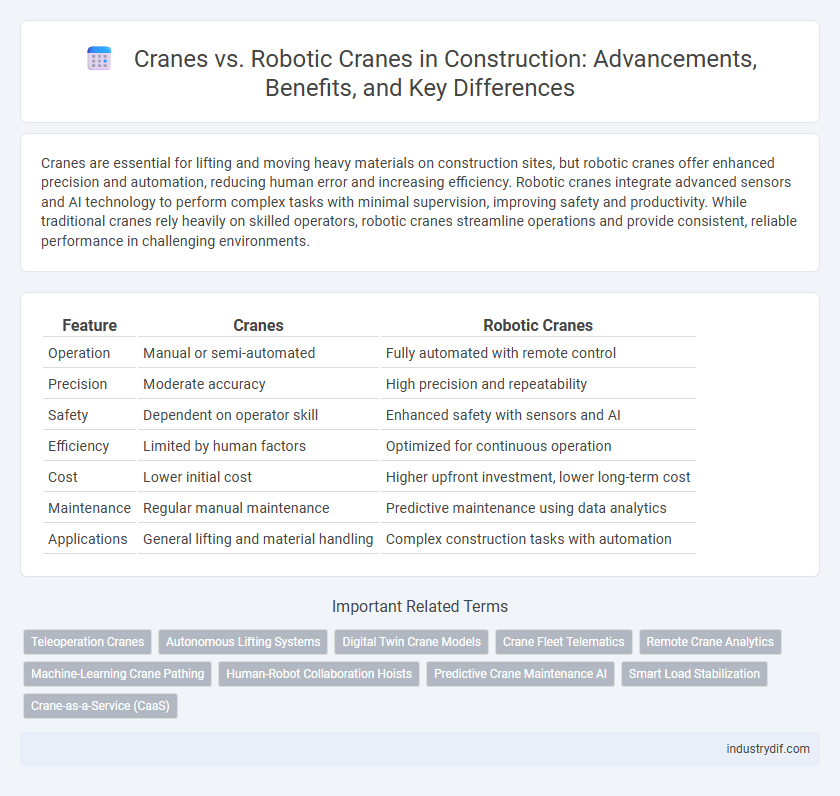

Table of Comparison

| Feature | Cranes | Robotic Cranes |

|---|---|---|

| Operation | Manual or semi-automated | Fully automated with remote control |

| Precision | Moderate accuracy | High precision and repeatability |

| Safety | Dependent on operator skill | Enhanced safety with sensors and AI |

| Efficiency | Limited by human factors | Optimized for continuous operation |

| Cost | Lower initial cost | Higher upfront investment, lower long-term cost |

| Maintenance | Regular manual maintenance | Predictive maintenance using data analytics |

| Applications | General lifting and material handling | Complex construction tasks with automation |

Overview of Traditional Cranes

Traditional cranes are essential heavy machinery in construction, designed to lift and move heavy materials vertically and horizontally. These cranes operate through manual controls and hydraulic systems, requiring skilled operators to ensure precise handling and safety on-site. Common types include tower cranes, mobile cranes, and crawler cranes, each optimized for specific tasks and environments in construction projects.

Introduction to Robotic Cranes

Robotic cranes integrate advanced automation technologies, enhancing precision and efficiency in construction lifting tasks while reducing human error and labor costs. Equipped with sensors, AI, and remote control capabilities, robotic cranes can perform complex maneuvers in confined or hazardous environments, improving overall site safety. Their adaptability and real-time data processing allow for seamless coordination with other automated construction equipment, driving productivity and project timelines forward.

Key Differences Between Traditional and Robotic Cranes

Traditional cranes rely on manual operation for lifting and moving heavy materials, whereas robotic cranes use automated systems and AI for precision and efficiency. Robotic cranes offer enhanced safety by minimizing human intervention and reducing the risk of accidents on construction sites. Maintenance requirements for robotic cranes involve advanced sensors and software diagnostics, contrasting with the mechanical upkeep typical of traditional cranes.

Technological Advancements in Crane Operations

Robotic cranes integrate advanced sensors, AI-driven control systems, and real-time data analytics, significantly enhancing precision and safety in construction operations. Unlike traditional cranes, robotic cranes enable remote operation and automated load management, reducing human error and increasing productivity. These technological advancements drive efficiency improvements and lower operational risks on modern construction sites.

Safety Features: Traditional vs Robotic Cranes

Traditional cranes rely on manual operation and basic safety mechanisms such as limit switches and emergency stop buttons, which can be prone to human error and slower response times. Robotic cranes integrate advanced sensors, real-time monitoring, and automated controls to detect hazards and prevent accidents proactively. These robotic safety features significantly reduce risks, enhance precision, and improve overall site safety compared to conventional crane systems.

Efficiency and Productivity Comparison

Robotic cranes significantly enhance efficiency by automating lifting processes, reducing human error, and allowing continuous operation without fatigue, which traditional cranes operated manually cannot match. These cranes integrate advanced sensors and AI to optimize load handling, improve precision in material placement, and minimize downtime through predictive maintenance. Consequently, productivity gains with robotic cranes surpass conventional cranes, delivering faster project completion times and lower labor costs in construction sites.

Cost Implications in Crane Selection

Traditional cranes typically involve higher ongoing labor and maintenance costs due to manual operation and mechanical wear. Robotic cranes, while entailing a higher upfront investment, offer significant savings through increased precision, reduced labor expenses, and minimized downtime. Evaluating the total cost of ownership, including installation, operation, and maintenance, is essential for efficient crane selection in construction projects.

Workforce and Skill Requirements

Traditional cranes rely on skilled operators who require extensive training and certification to ensure safe and efficient handling of heavy materials. Robotic cranes, equipped with automated systems and advanced sensors, reduce the need for manual operation, shifting workforce demands toward technical roles in programming, monitoring, and maintenance. This transition enhances safety by minimizing human error but necessitates a workforce proficient in robotics, software management, and equipment troubleshooting.

Sustainability and Environmental Impact

Robotic cranes reduce energy consumption and minimize carbon emissions through precise automation and electric power systems, enhancing sustainability compared to traditional diesel-powered cranes. Their ability to perform repetitive tasks with high efficiency decreases material waste and lowers noise pollution on construction sites. Integration of robotic cranes supports green building practices by optimizing resource use and reducing the overall environmental footprint of construction projects.

Future Trends in Crane Technology

Future trends in crane technology emphasize automation and AI integration, with robotic cranes offering enhanced precision, safety, and operational efficiency compared to traditional cranes. Advanced sensor systems and machine learning algorithms enable robotic cranes to perform complex lifts with minimal human intervention, reducing workplace accidents and downtime. The construction industry is rapidly adopting these innovations to improve project timelines and cost-effectiveness while addressing labor shortages.

Related Important Terms

Teleoperation Cranes

Teleoperation cranes enhance construction site safety and efficiency by enabling remote control of heavy lifting tasks, reducing the need for operators to be physically present in hazardous environments. Compared to traditional cranes, teleoperated robotic cranes offer precision, real-time monitoring, and integration with digital construction management systems, streamlining complex lifting operations and minimizing downtime.

Autonomous Lifting Systems

Autonomous lifting systems in construction leverage robotic cranes equipped with advanced sensors and AI algorithms to perform precise, efficient, and safe material handling tasks, significantly reducing human error and labor costs. These robotic cranes enable real-time site adaptation and predictive maintenance, optimizing workflow compared to traditional cranes that rely heavily on manual operation.

Digital Twin Crane Models

Digital twin crane models enable real-time simulation and monitoring of both traditional and robotic cranes, enhancing operational efficiency and predictive maintenance in construction projects. Integrating sensor data with digital twins allows precise control of robotic cranes, reducing downtime and improving safety compared to conventional cranes.

Crane Fleet Telematics

Crane fleet telematics enhances operational efficiency by providing real-time tracking, predictive maintenance alerts, and utilization analytics for traditional cranes and robotic cranes alike. Integrating telematics in robotic cranes further optimizes automated control and safety monitoring, reducing downtime and improving project timelines on construction sites.

Remote Crane Analytics

Remote crane analytics enhances operational efficiency by providing real-time data on load weights, equipment status, and environmental conditions, enabling proactive maintenance and minimizing downtime. Robotic cranes integrated with advanced sensors and IoT technology outperform traditional cranes by offering precise remote monitoring and automated performance optimization, improving safety and productivity on construction sites.

Machine-Learning Crane Pathing

Machine-learning crane pathing leverages advanced algorithms to optimize movement trajectories, reducing operational inefficiencies and collision risks compared to traditional cranes. Robotic cranes equipped with this technology enable real-time adaptability on construction sites, enhancing precision and safety in heavy lifting tasks.

Human-Robot Collaboration Hoists

Human-robot collaboration hoists in construction enhance safety and efficiency by combining the precision and strength of robotic cranes with the adaptability and decision-making skills of human operators. This synergy reduces manual labor risks while increasing load handling accuracy and project speed.

Predictive Crane Maintenance AI

Predictive Crane Maintenance AI enhances traditional cranes by analyzing sensor data to forecast mechanical failures, reducing downtime and maintenance costs. Robotic cranes integrated with AI systems enable real-time monitoring and automated adjustments, significantly improving operational efficiency and safety on construction sites.

Smart Load Stabilization

Smart load stabilization in robotic cranes utilizes advanced sensors and AI algorithms to dynamically adjust movements, significantly reducing sway and enhancing precision compared to traditional cranes. This technology improves safety and efficiency on construction sites by minimizing load oscillation and enabling smoother, more controlled lifting operations.

Crane-as-a-Service (CaaS)

Crane-as-a-Service (CaaS) transforms traditional construction workflows by integrating robotic cranes that offer enhanced precision, reduced labor costs, and real-time operational analytics compared to conventional cranes. This subscription-based model enables project scalability and minimizes downtime through predictive maintenance powered by AI, optimizing overall site productivity.

Cranes vs Robotic Crane Infographic

industrydif.com

industrydif.com