Assembly line manufacturing streamlines production by moving products sequentially through fixed stations, optimizing high-volume output and consistency. Cellular manufacturing organizes workstations into small, flexible groups focusing on similar processes, enhancing customization and reducing lead times. Choosing between the two depends on product variety, volume requirements, and the need for operational flexibility.

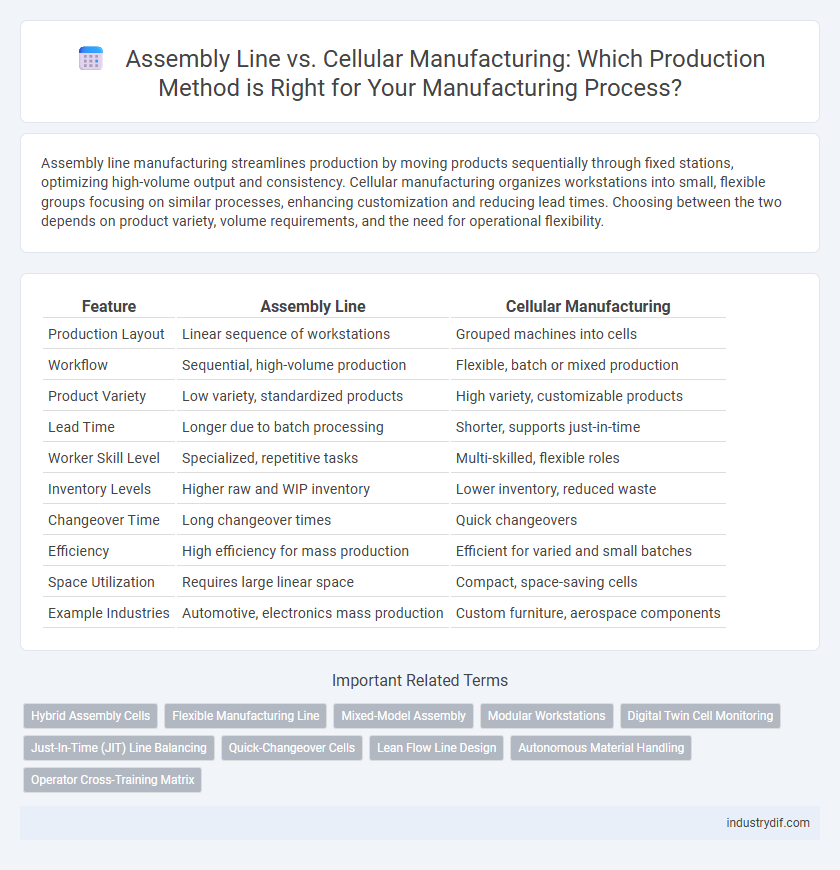

Table of Comparison

| Feature | Assembly Line | Cellular Manufacturing |

|---|---|---|

| Production Layout | Linear sequence of workstations | Grouped machines into cells |

| Workflow | Sequential, high-volume production | Flexible, batch or mixed production |

| Product Variety | Low variety, standardized products | High variety, customizable products |

| Lead Time | Longer due to batch processing | Shorter, supports just-in-time |

| Worker Skill Level | Specialized, repetitive tasks | Multi-skilled, flexible roles |

| Inventory Levels | Higher raw and WIP inventory | Lower inventory, reduced waste |

| Changeover Time | Long changeover times | Quick changeovers |

| Efficiency | High efficiency for mass production | Efficient for varied and small batches |

| Space Utilization | Requires large linear space | Compact, space-saving cells |

| Example Industries | Automotive, electronics mass production | Custom furniture, aerospace components |

Overview of Assembly Line and Cellular Manufacturing

Assembly line manufacturing organizes production in a linear sequence, where each worker or machine performs a specific task repetitively, optimizing high-volume output and reducing cycle time. Cellular manufacturing groups different processes and machines into cells dedicated to producing similar product families, enhancing flexibility and reducing work-in-progress inventory. Both methods aim to improve efficiency, but assembly lines excel in mass production while cellular manufacturing supports customization and rapid changeovers.

Key Principles of Assembly Line Manufacturing

Assembly line manufacturing relies on a continuous flow of standardized parts through sequential workstations, emphasizing efficiency, specialization, and minimizing worker movement. The key principles include task segmentation, where each worker performs a specific operation, and synchronization to maintain a steady production pace. This method enhances productivity by reducing cycle time and optimizing resource allocation in mass production environments.

Fundamentals of Cellular Manufacturing

Cellular manufacturing organizes workstations and equipment into small, self-contained units called cells, each dedicated to producing a family of similar products, improving workflow and reducing lead times. This approach enhances flexibility by minimizing transportation waste and facilitates faster detection of defects within cells, contrasting with traditional assembly lines that are linear and often more rigid. Emphasizing teamwork and continuous improvement, cellular manufacturing supports just-in-time production and lean manufacturing principles, driving efficiency and reducing overall operational costs.

Workflow Differences: Linear vs. Cell-Based Approaches

Assembly line manufacturing organizes workflow in a sequential, linear progression where each workstation performs a specific task in a fixed order, maximizing efficiency for high-volume production. In contrast, cellular manufacturing groups diverse machines into cells that handle a complete set of operations for a product or component, promoting flexibility and reducing lead times. This cell-based approach fosters a more collaborative work environment, enabling quicker adjustments to product variations and minimizing material handling compared to the rigid structure of assembly lines.

Efficiency and Productivity Comparison

Assembly line manufacturing optimizes efficiency through standardized, repetitive tasks, facilitating high-volume production with minimal variation, which reduces cycle time and maximizes output. Cellular manufacturing enhances productivity by grouping diverse yet related operations into cells, promoting flexibility and reducing work-in-progress inventory while enabling quicker adjustments to product changes. Compared to assembly lines, cellular manufacturing often improves overall efficiency in multi-product environments due to its balanced workload and increased worker skill utilization.

Flexibility and Customization Capabilities

Assembly line manufacturing offers high efficiency for standardized products but has limited flexibility in handling product variations. Cellular manufacturing enhances customization capabilities by grouping different machines into cells, enabling quicker adjustments for diverse product designs. This structure supports small batch production and rapid changeovers, making it ideal for flexible manufacturing environments.

Impact on Quality Control

Assembly line manufacturing ensures consistent quality through standardized processes and repetitive tasks, minimizing variability and defects. Cellular manufacturing enhances quality control by enabling focused workmanship within dedicated cells, promoting quicker identification and resolution of defects. The localized teamwork in cellular setups often leads to higher product quality and reduced rework compared to the sequential flow of assembly lines.

Cost Implications and Investment Considerations

Assembly line manufacturing often involves higher upfront capital investment in specialized equipment and conveyor systems, driving economies of scale but increasing fixed costs. Cellular manufacturing reduces work-in-progress inventory and enhances labor flexibility, leading to lower operating costs but may require significant investment in cross-trained personnel and adaptable machinery. Cost implications must balance fixed asset expenses against operational efficiency gains when choosing between these manufacturing approaches.

Suitability for Different Product Types

Assembly line manufacturing suits high-volume, standardized products such as automobiles or electronics, enabling consistent output through sequential processes. Cellular manufacturing excels with small-to-medium batch sizes and customized or varied products, as cells group different machines by product family to enhance flexibility and reduce lead times. Choosing between the two depends on product complexity, volume, and the need for adaptability within the production system.

Future Trends in Manufacturing Systems

Assembly line manufacturing will increasingly integrate automation and artificial intelligence, enhancing speed and precision in mass production environments. Cellular manufacturing is evolving with flexible robotics and real-time data analytics, enabling customized production and reducing lead times. Future trends emphasize smart manufacturing systems that combine these approaches to optimize efficiency, adaptability, and sustainability in production processes.

Related Important Terms

Hybrid Assembly Cells

Hybrid assembly cells combine the efficiency of traditional assembly lines with the flexibility of cellular manufacturing, optimizing production flow and reducing waste. By integrating modular workstations and cross-trained operators, hybrid cells enhance both output volume and customization capabilities in manufacturing processes.

Flexible Manufacturing Line

Flexible manufacturing lines enhance production efficiency by allowing rapid reconfiguration of assembly processes to accommodate varied product designs and volumes. Unlike traditional assembly lines, cellular manufacturing groups machines and workstations into cells to streamline workflow, yet flexible lines provide greater adaptability for custom orders and fluctuating demand.

Mixed-Model Assembly

Mixed-model assembly enhances production flexibility by allowing multiple product variants to be assembled on the same line without significant changeover time. Cellular manufacturing complements this approach by grouping diverse but related product families into cells, reducing material handling and improving workflow efficiency for mixed-model production environments.

Modular Workstations

Modular workstations in cellular manufacturing enhance flexibility by grouping multifunctional equipment arranged in compact cells, enabling streamlined workflow and reduced material handling compared to traditional assembly lines. This configuration minimizes downtime and improves customization capabilities, driving higher efficiency and responsiveness in modern manufacturing environments.

Digital Twin Cell Monitoring

Digital Twin Cell Monitoring enables real-time simulation and optimization in both assembly line and cellular manufacturing by creating virtual replicas of production cells, enhancing precision and reducing downtime. This technology facilitates predictive maintenance and workflow adjustments, driving efficiency and flexibility in complex manufacturing environments.

Just-In-Time (JIT) Line Balancing

Just-In-Time (JIT) line balancing in assembly lines optimizes workflow by minimizing inventory and synchronizing production rates, ensuring efficient component flow and reducing lead times. In contrast, cellular manufacturing employs JIT principles within clustered workstations to enhance flexibility and responsiveness, allowing for smoother transitions between tasks and improved overall productivity.

Quick-Changeover Cells

Quick-changeover cells in cellular manufacturing significantly reduce setup times by organizing workstations to facilitate rapid tool and part swaps, enhancing flexibility and responsiveness compared to traditional assembly lines. This approach minimizes downtime, increases productivity, and supports lean manufacturing goals by enabling smaller batch sizes and more efficient workflow.

Lean Flow Line Design

Lean flow line design in assembly line manufacturing emphasizes standardized tasks, sequential workstations, and minimized cycle time to achieve high-volume production efficiency. Cellular manufacturing organizes workstations into small, multifunctional cells that promote flexibility, reduce waste, and enhance continuous flow by grouping similar processes for leaner throughput.

Autonomous Material Handling

Autonomous material handling in assembly lines utilizes fixed, conveyor-based systems to streamline repetitive tasks, enhancing speed and consistency across large volumes of standardized products. In contrast, cellular manufacturing adopts flexible, robot-guided autonomous vehicles (AGVs) to transport materials between specialized workstations, supporting customized production and reducing changeover times.

Operator Cross-Training Matrix

An operator cross-training matrix enhances workforce flexibility by detailing skill levels across multiple tasks in both assembly line and cellular manufacturing setups. Cellular manufacturing benefits more from this matrix through streamlined task rotation and balanced workloads, improving overall efficiency and reducing downtime compared to traditional assembly lines.

Assembly Line vs Cellular Manufacturing Infographic

industrydif.com

industrydif.com