Traditional machining relies on subtractive processes to shape materials through cutting, drilling, and milling, offering high precision and surface finish. Hybrid manufacturing integrates additive techniques with conventional machining, enabling complex geometries and reduced material waste while maintaining accuracy. This combination enhances production flexibility and accelerates prototype development in modern manufacturing environments.

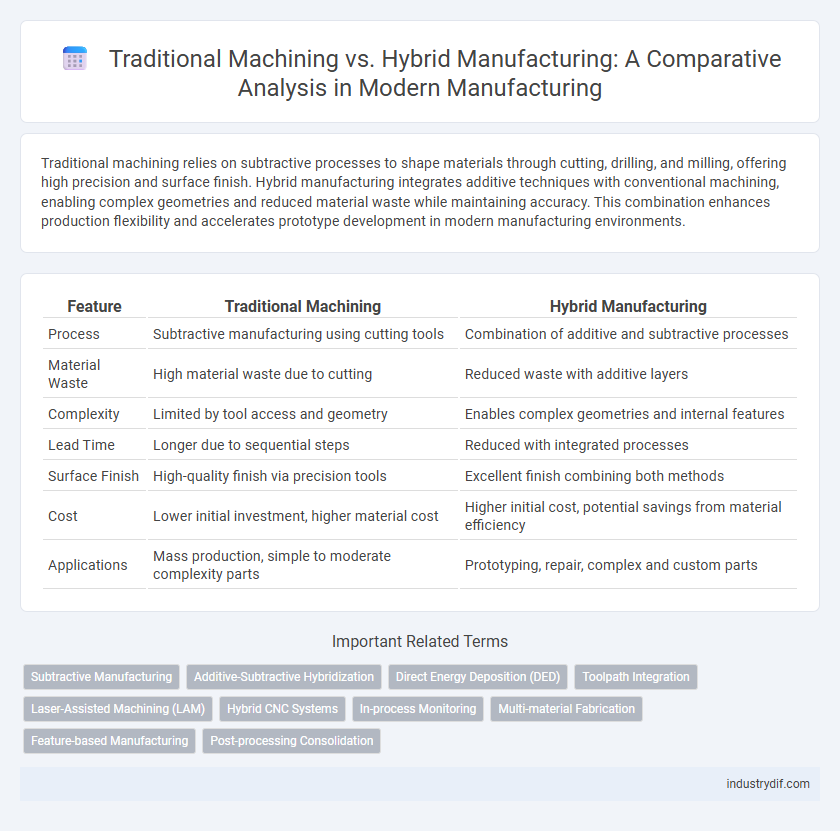

Table of Comparison

| Feature | Traditional Machining | Hybrid Manufacturing |

|---|---|---|

| Process | Subtractive manufacturing using cutting tools | Combination of additive and subtractive processes |

| Material Waste | High material waste due to cutting | Reduced waste with additive layers |

| Complexity | Limited by tool access and geometry | Enables complex geometries and internal features |

| Lead Time | Longer due to sequential steps | Reduced with integrated processes |

| Surface Finish | High-quality finish via precision tools | Excellent finish combining both methods |

| Cost | Lower initial investment, higher material cost | Higher initial cost, potential savings from material efficiency |

| Applications | Mass production, simple to moderate complexity parts | Prototyping, repair, complex and custom parts |

Introduction to Traditional Machining and Hybrid Manufacturing

Traditional machining involves subtractive manufacturing processes such as milling, turning, and drilling, where material is removed from a solid workpiece to create a final part. Hybrid manufacturing combines additive manufacturing techniques like 3D printing with traditional subtractive methods, enabling complex geometries and enhanced material properties. This integration improves production efficiency, reduces waste, and allows for more customization in manufacturing workflows.

Key Differences Between Traditional and Hybrid Methods

Traditional machining relies on subtractive processes that remove material from a workpiece using tools like lathes and mills, offering high precision but limited design complexity. Hybrid manufacturing combines additive manufacturing with conventional subtractive techniques, enabling the production of complex geometries, reducing material waste, and shortening lead times. Key differences include enhanced design flexibility, improved material utilization, and the ability to create integrated components in hybrid methods versus the more rigid, sequential approach of traditional machining.

Core Processes in Traditional Machining

Core processes in traditional machining include turning, milling, drilling, and grinding, where material is removed from a workpiece to achieve desired shapes and tolerances. These subtractive methods rely heavily on cutting tools, machine stability, and precision programming to ensure accuracy and surface finish quality. Traditional machining excels in producing complex geometries with tight dimensional control, particularly for metal components in automotive, aerospace, and industrial manufacturing sectors.

Defining Hybrid Manufacturing Technologies

Hybrid manufacturing technologies combine additive manufacturing and traditional subtractive machining processes within a single system to enhance production efficiency and precision. These technologies enable complex geometries to be built layer-by-layer and then refined through CNC milling, turning, or grinding, resulting in improved surface finish and dimensional accuracy. The integration of both processes reduces lead time, material waste, and post-processing steps compared to conventional machining alone.

Material Compatibility and Flexibility

Traditional machining excels with metals like aluminum, steel, and titanium, offering high precision but limited flexibility for complex geometries. Hybrid manufacturing combines additive and subtractive processes, enhancing material compatibility by integrating polymers, composites, and metals in a single workflow. This approach increases flexibility, enabling the production of intricate parts with varied material properties unattainable by conventional methods.

Production Speed and Efficiency Comparison

Traditional machining relies on subtractive processes that often require multiple setups and longer cycle times, limiting production speed and efficiency. Hybrid manufacturing combines additive and subtractive methods within a single setup, significantly reducing lead times and material waste while enhancing precision. This integration accelerates production stages and optimizes resource use, resulting in higher overall manufacturing efficiency.

Cost Implications: Initial Investment and Operational Expenses

Traditional machining involves lower initial investment due to simpler equipment requirements but incurs higher operational expenses from longer machining times and material waste. Hybrid manufacturing demands a higher upfront cost for advanced machinery integrating additive and subtractive processes, yet it reduces operational expenses through improved material efficiency and shorter production cycles. Over time, hybrid manufacturing can offer significant cost savings despite the initial expenditure, especially in complex or custom production runs.

Quality, Precision, and Surface Finish Considerations

Traditional machining offers consistent quality and high precision by removing material through controlled cutting processes, ensuring tight tolerances and smooth surface finishes. Hybrid manufacturing combines additive and subtractive techniques, enhancing precision in complex geometries while improving surface finish by reducing post-processing requirements. Surface finish quality in hybrid methods often surpasses traditional machining alone, as additive layers can be optimized before final machining refinements.

Application Areas and Industry Adoption

Traditional machining remains prevalent in industries such as aerospace, automotive, and heavy equipment manufacturing due to its precision in subtractive processes for metal components. Hybrid manufacturing, combining additive and subtractive methods, is rapidly gaining traction in high-tech sectors like medical devices and aerospace for producing complex geometries and reducing lead times. Adoption of hybrid technology is accelerating in advanced manufacturing environments aiming for enhanced customization and material efficiency.

Future Trends in Manufacturing: Evolving Integration

Future trends in manufacturing emphasize the evolving integration of traditional machining with hybrid manufacturing, combining subtractive and additive processes to enhance precision and reduce lead times. Advanced automation and real-time data analytics drive this integration, enabling more flexible, cost-effective production cycles and minimizing material waste. Smart factories increasingly adopt hybrid systems to meet complex design demands and accelerate innovation in sectors like aerospace and automotive.

Related Important Terms

Subtractive Manufacturing

Traditional subtractive manufacturing relies exclusively on processes like milling, turning, and drilling to remove material from a solid workpiece, offering high precision and surface finish but often resulting in longer production times and higher material waste. Hybrid manufacturing combines subtractive methods with additive techniques, enhancing design flexibility, reducing lead times, and minimizing material consumption while maintaining the accuracy and repeatability of conventional machining.

Additive-Subtractive Hybridization

Additive-subtractive hybridization in manufacturing integrates 3D printing with traditional CNC machining, enabling complex geometries with enhanced precision and reduced lead times. This synergy maximizes material efficiency and surface finish quality, surpassing the limitations of standalone additive or subtractive processes.

Direct Energy Deposition (DED)

Traditional machining relies on subtractive processes, removing material from a workpiece to achieve desired dimensions, whereas Hybrid Manufacturing integrates Direct Energy Deposition (DED) to combine additive and subtractive techniques for enhanced design flexibility and material efficiency. DED enables precise metal deposition layer-by-layer, allowing repair, coating, and complex geometries while reducing waste and lead times compared to conventional subtractive-only methods.

Toolpath Integration

Traditional machining relies on predefined, segmented toolpaths tailored for subtractive processes, often leading to increased production time and limited design complexity. Hybrid manufacturing integrates additive and subtractive toolpaths within a unified system, enabling seamless transitions, improved precision, and enhanced customization capabilities in complex part fabrication.

Laser-Assisted Machining (LAM)

Laser-Assisted Machining (LAM) enhances traditional machining by using a laser beam to soften hard materials before cutting, improving tool life and surface finish while reducing machining forces and thermal damage. This hybrid manufacturing method enables higher precision and efficiency in processing difficult-to-machine materials like titanium and ceramics compared to conventional techniques.

Hybrid CNC Systems

Hybrid CNC systems combine additive manufacturing and traditional subtractive machining processes within a single platform, enhancing precision and reducing production time by enabling complex geometries with minimal material waste. These systems improve manufacturing flexibility and cost-efficiency, especially for aerospace and automotive industries requiring high-performance, customized components.

In-process Monitoring

In-process monitoring in traditional machining primarily relies on periodic manual inspections and basic sensor feedback, which can lead to delayed detection of tool wear or defects. Hybrid manufacturing integrates advanced real-time sensors and AI-driven analytics, enabling continuous monitoring and immediate adjustment to enhance precision, reduce downtime, and improve overall production quality.

Multi-material Fabrication

Traditional machining excels in producing high-precision components from single materials through subtractive processes, while hybrid manufacturing integrates additive and subtractive techniques, enabling efficient multi-material fabrication with complex geometries and material gradation. Hybrid systems enhance product performance by combining metals, polymers, and ceramics within a single build, reducing assembly steps and increasing design flexibility in advanced manufacturing applications.

Feature-based Manufacturing

Feature-based manufacturing in traditional machining relies on subtractive processes targeting specific geometries, whereas hybrid manufacturing combines additive and subtractive methods to enhance feature complexity and reduce lead times. Integrating feature-based design with hybrid techniques optimizes material usage and improves precision, enabling the production of intricate parts with fewer setups and increased flexibility.

Post-processing Consolidation

Post-processing consolidation in traditional machining often requires extensive manual finishing to achieve desired tolerances and surface quality, increasing production time and costs. Hybrid manufacturing integrates additive and subtractive processes in a single setup, significantly reducing post-processing steps and enhancing precision and efficiency in final component fabrication.

Traditional Machining vs Hybrid Manufacturing Infographic

industrydif.com

industrydif.com