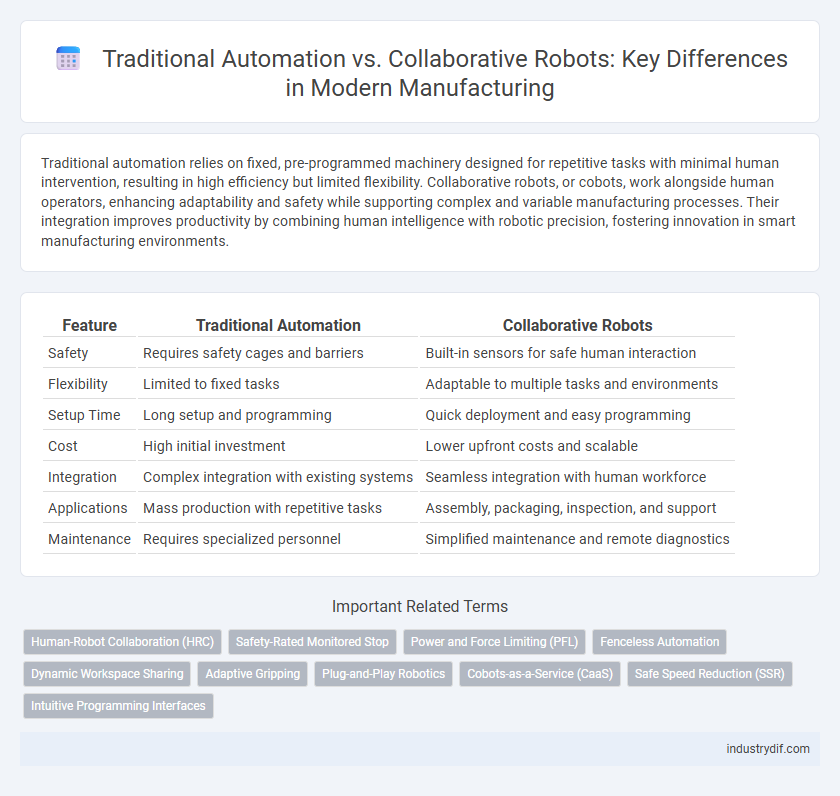

Traditional automation relies on fixed, pre-programmed machinery designed for repetitive tasks with minimal human intervention, resulting in high efficiency but limited flexibility. Collaborative robots, or cobots, work alongside human operators, enhancing adaptability and safety while supporting complex and variable manufacturing processes. Their integration improves productivity by combining human intelligence with robotic precision, fostering innovation in smart manufacturing environments.

Table of Comparison

| Feature | Traditional Automation | Collaborative Robots |

|---|---|---|

| Safety | Requires safety cages and barriers | Built-in sensors for safe human interaction |

| Flexibility | Limited to fixed tasks | Adaptable to multiple tasks and environments |

| Setup Time | Long setup and programming | Quick deployment and easy programming |

| Cost | High initial investment | Lower upfront costs and scalable |

| Integration | Complex integration with existing systems | Seamless integration with human workforce |

| Applications | Mass production with repetitive tasks | Assembly, packaging, inspection, and support |

| Maintenance | Requires specialized personnel | Simplified maintenance and remote diagnostics |

Introduction to Automation in Manufacturing

Traditional automation in manufacturing relies on fixed, pre-programmed machines designed for repetitive tasks, offering high speed and precision but limited flexibility. Collaborative robots (cobots) are advanced robotic systems engineered to work safely alongside human operators, enhancing adaptability and efficiency on the production line. Integrating cobots facilitates real-time interaction and dynamic task allocation, revolutionizing automation by combining human skills with robotic consistency.

Defining Traditional Automation Systems

Traditional automation systems in manufacturing involve pre-programmed machines performing repetitive tasks with minimal flexibility, relying heavily on fixed hardware like conveyor belts, robotic arms, and PLCs (Programmable Logic Controllers). These systems prioritize high-speed production and consistent output but require significant upfront programming and lack adaptability to dynamic environments. Their operation often demands safety barriers and isolation from human workers due to limited sensing and interaction capabilities.

Understanding Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work safely alongside human operators without extensive safety barriers, enhancing flexibility and efficiency on manufacturing floors. Unlike traditional automation, which often requires fixed programming and physical separation, cobots use advanced sensors and AI to adapt to dynamic environments and tasks. Their ease of integration reduces deployment time and costs while increasing productivity and worker safety in manufacturing processes.

Key Differences Between Traditional Automation and Cobots

Traditional automation systems operate in fixed, pre-programmed environments requiring safety barriers and limited flexibility, whereas collaborative robots (cobots) are designed to work safely alongside human workers without extensive guarding. Cobots offer adaptive learning capabilities and easy reprogramming for versatile tasks, contrasting with traditional automation's rigid, repetitive functions. The integration of sensors and advanced AI in cobots enhances human-robot interaction, improving efficiency and fostering dynamic manufacturing processes.

Advantages of Traditional Automation

Traditional automation excels in high-volume, repetitive manufacturing tasks due to its consistent precision and ability to operate 24/7 without fatigue. It offers a robust solution for processes requiring high-speed production and minimal human intervention, leading to increased efficiency and reduced labor costs. Furthermore, traditional automation systems typically have lower initial training requirements and established integration protocols with existing manufacturing workflows.

Benefits of Collaborative Robots in Manufacturing

Collaborative robots enhance manufacturing by enabling safer human-robot interaction with built-in sensors and force limiters, reducing workplace injuries. These robots improve flexibility on the production floor, easily adapting to various tasks without extensive reprogramming, which increases efficiency and lowers operational costs. Their ability to work alongside human operators accelerates complex assembly processes, boosting productivity and product quality.

Safety Considerations: Traditional Automation vs Cobots

Traditional automation systems often require safety cages and barriers to protect workers from hazardous machinery, limiting human-machine interaction. Collaborative robots (cobots) are designed with advanced sensors and force-limiting features, enabling safe direct collaboration with human operators in manufacturing environments. Safety standards such as ISO/TS 15066 specifically address cobot operation, ensuring risk assessments and safe speed limits for enhanced workplace safety.

Flexibility and Scalability in Modern Production Lines

Traditional automation systems provide high-speed production but often lack the flexibility to adapt quickly to changing product designs or demand fluctuations. Collaborative robots (cobots) offer greater scalability and ease of reprogramming, allowing manufacturers to efficiently handle small batch sizes and customized orders. Integrating cobots into modern production lines enhances operational agility and responsiveness, driving improved productivity and cost-effectiveness.

Cost Analysis: Investment and ROI Comparison

Traditional automation often demands high upfront capital investments in specialized machinery and lengthy integration timelines, resulting in extended payback periods. Collaborative robots (cobots) offer lower initial costs due to their flexible deployment and ease of programming, accelerating return on investment for small to medium-sized manufacturers. Cost analysis reveals cobots reduce expenses related to workforce training and maintenance while enhancing scalability, making them a financially attractive alternative to conventional robotic systems.

Future Trends: Integrating Automation and Collaborative Robotics

Future trends in manufacturing emphasize the integration of traditional automation systems with collaborative robots (cobots) to enhance operational efficiency and flexibility. Advanced sensor technology and artificial intelligence enable seamless human-robot interaction, improving precision and safety on the production floor. Hybrid automation frameworks combining fixed robotic arms with adaptable cobots drive innovation in smart factories, optimizing throughput and minimizing downtime.

Related Important Terms

Human-Robot Collaboration (HRC)

Human-Robot Collaboration (HRC) enhances manufacturing efficiency by combining traditional automation's precision with collaborative robots' adaptability, enabling seamless interaction and shared workspaces between humans and robots. Collaborative robots improve safety and flexibility on production lines by using advanced sensors and AI to respond dynamically to human presence, unlike rigid traditional automation systems.

Safety-Rated Monitored Stop

Safety-rated monitored stop in traditional automation relies on fully stopping machinery during human intervention to ensure operator safety, resulting in production downtime. Collaborative robots enhance safety by automatically pausing tasks when humans enter the workspace, allowing seamless human-robot interaction without halting overall manufacturing processes.

Power and Force Limiting (PFL)

Collaborative robots (cobots) utilize power and force limiting (PFL) technology to operate safely alongside human workers by automatically reducing speed or force upon contact, unlike traditional automation systems that rely on physical barriers and require higher power for dedicated tasks. This intrinsic safety feature of cobots enhances flexibility on the manufacturing floor, enabling efficient human-robot collaboration without compromising operational productivity or worker safety.

Fenceless Automation

Fenceless automation utilizing collaborative robots (cobots) enables seamless human-robot interaction on manufacturing floors, enhancing flexibility and safety without the need for physical barriers typical in traditional automation. This approach reduces space requirements and operational costs while allowing faster integration and adaptability in complex production environments.

Dynamic Workspace Sharing

Traditional automation relies on fixed, segregated workspaces designed for repetitive tasks, limiting flexibility in manufacturing environments. Collaborative robots (cobots) enable dynamic workspace sharing by working safely alongside human operators, increasing productivity and adaptability on the factory floor.

Adaptive Gripping

Traditional automation systems rely on fixed, rigid grippers designed for repetitive tasks, limiting flexibility and adaptability in manufacturing processes. Collaborative robots feature adaptive gripping technology with sensors and intelligent control systems that enable precise handling of varied and delicate components, enhancing efficiency and reducing downtime.

Plug-and-Play Robotics

Plug-and-play robotics enable collaborative robots (cobots) to be seamlessly integrated into traditional manufacturing automation systems without extensive programming or setup, significantly reducing deployment time and increasing operational flexibility. Unlike conventional automation that requires rigid configurations and specialized engineering, plug-and-play cobots offer adaptive, user-friendly interaction, enhancing productivity and enabling rapid reconfiguration for varied production tasks.

Cobots-as-a-Service (CaaS)

Cobots-as-a-Service (CaaS) revolutionizes traditional automation by offering flexible, scalable, and cost-efficient deployment of collaborative robots, enabling manufacturers to integrate advanced robotics without significant upfront investment. This service model enhances productivity and adaptability on the factory floor by providing ongoing maintenance, software updates, and customization tailored to evolving production needs.

Safe Speed Reduction (SSR)

Traditional automation relies on fixed safety barriers and complete shutdowns to ensure operator safety, while collaborative robots (cobots) implement Safe Speed Reduction (SSR) to dynamically lower operational speed when humans enter a designated proximity zone, enhancing both productivity and workplace safety. SSR technology in cobots uses advanced sensors and algorithms to modulate robot speed in real-time, minimizing collision risks without interrupting manufacturing processes.

Intuitive Programming Interfaces

Traditional automation relies on complex programming languages and specialized skills, often requiring extensive training and longer setup times. Collaborative robots (cobots) utilize intuitive programming interfaces with drag-and-drop features and teach-by-demonstration capabilities, significantly reducing programming time and enabling operators without advanced coding expertise to easily configure tasks.

Traditional Automation vs Collaborative Robots Infographic

industrydif.com

industrydif.com