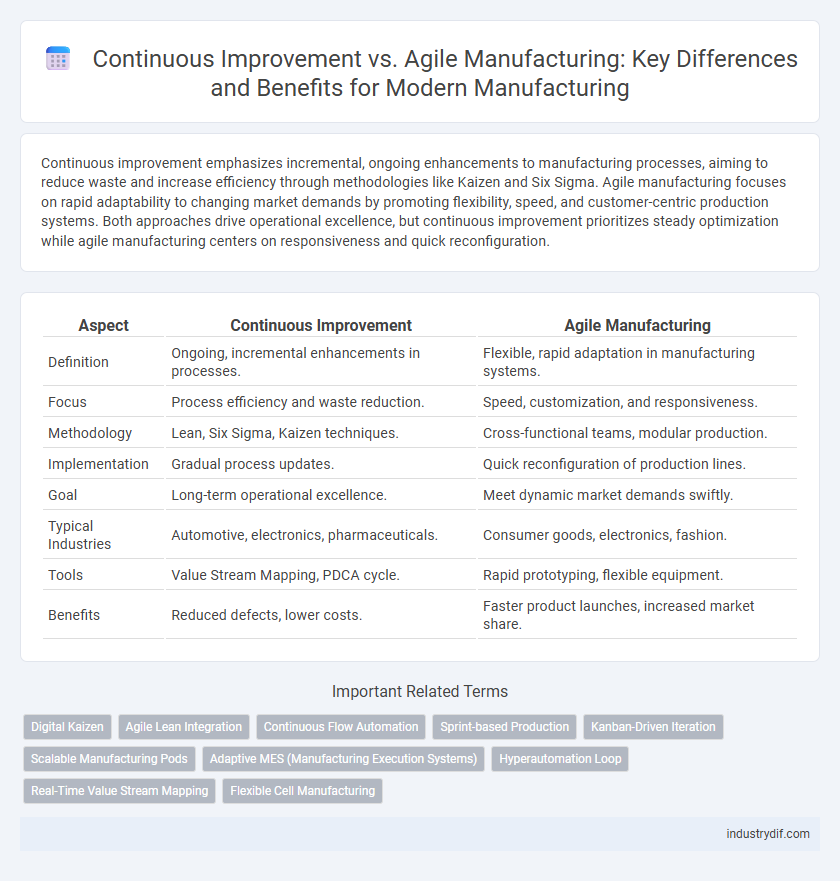

Continuous improvement emphasizes incremental, ongoing enhancements to manufacturing processes, aiming to reduce waste and increase efficiency through methodologies like Kaizen and Six Sigma. Agile manufacturing focuses on rapid adaptability to changing market demands by promoting flexibility, speed, and customer-centric production systems. Both approaches drive operational excellence, but continuous improvement prioritizes steady optimization while agile manufacturing centers on responsiveness and quick reconfiguration.

Table of Comparison

| Aspect | Continuous Improvement | Agile Manufacturing |

|---|---|---|

| Definition | Ongoing, incremental enhancements in processes. | Flexible, rapid adaptation in manufacturing systems. |

| Focus | Process efficiency and waste reduction. | Speed, customization, and responsiveness. |

| Methodology | Lean, Six Sigma, Kaizen techniques. | Cross-functional teams, modular production. |

| Implementation | Gradual process updates. | Quick reconfiguration of production lines. |

| Goal | Long-term operational excellence. | Meet dynamic market demands swiftly. |

| Typical Industries | Automotive, electronics, pharmaceuticals. | Consumer goods, electronics, fashion. |

| Tools | Value Stream Mapping, PDCA cycle. | Rapid prototyping, flexible equipment. |

| Benefits | Reduced defects, lower costs. | Faster product launches, increased market share. |

Defining Continuous Improvement in Manufacturing

Continuous Improvement in manufacturing refers to an ongoing effort to enhance processes, products, or services by eliminating waste, reducing variability, and increasing efficiency through methods like Lean, Six Sigma, and Kaizen. It emphasizes incremental changes driven by employee involvement, data analysis, and standardized procedures to achieve sustained operational excellence. This approach contrasts with Agile Manufacturing by prioritizing steady, long-term process optimization over rapid adaptability and flexibility in production.

Understanding Agile Manufacturing Principles

Agile manufacturing principles emphasize flexibility, rapid response to market changes, and cross-functional collaboration to enhance production efficiency and customer satisfaction. Unlike traditional continuous improvement, which focuses on incremental enhancements, agile manufacturing integrates real-time data, adaptive workflows, and modular processes to accelerate innovation and reduce lead times. Key components include just-in-time production, lean inventory management, and empowered teams that drive dynamic decision-making throughout the manufacturing cycle.

Core Differences: Continuous Improvement vs Agile Manufacturing

Continuous Improvement emphasizes incremental, ongoing enhancements to manufacturing processes through methods like Six Sigma and Lean, aiming for efficiency and defect reduction. Agile Manufacturing prioritizes flexibility and rapid response to market changes by integrating adaptable technologies and cross-functional teams to swiftly produce customized products. Core differences lie in Continuous Improvement's steady, process-centered optimization versus Agile Manufacturing's dynamic, market-driven adaptability and speed.

Key Benefits of Continuous Improvement Approaches

Continuous Improvement approaches in manufacturing drive enhanced operational efficiency by systematically eliminating waste and reducing process variability, leading to consistent quality improvements. These methods foster a culture of employee involvement and data-driven decision making, which accelerates problem-solving and innovation. Emphasizing incremental enhancements, Continuous Improvement ensures sustainable growth and long-term competitiveness in the manufacturing sector.

Advantages of Agile Manufacturing Strategies

Agile manufacturing strategies offer enhanced flexibility and rapid responsiveness to market changes, enabling companies to customize products efficiently and reduce lead times. This approach leverages advanced technologies and cross-functional teams to accelerate innovation and improve supply chain collaboration. By prioritizing adaptability and customer-driven production, agile manufacturing supports sustained competitive advantage in dynamic markets.

Implementation Challenges for Both Methodologies

Continuous Improvement faces implementation challenges such as employee resistance to ongoing changes and the need for a strong organizational culture supporting incremental progress. Agile Manufacturing encounters difficulties in quickly adapting workflows and supply chains to dynamic market demands while maintaining quality standards. Both methodologies require significant management commitment and resource allocation to successfully embed flexibility and efficiency into manufacturing processes.

Impact on Production Efficiency and Flexibility

Continuous Improvement drives production efficiency by systematically identifying and eliminating waste, enhancing processes through iterative adjustments that reduce cycle times and improve quality control. Agile Manufacturing increases flexibility by enabling rapid adaptation to market changes, utilizing modular equipment and cross-trained teams to customize products quickly without significant downtime. Combining Continuous Improvement's efficiency gains with Agile Manufacturing's responsiveness results in a production system capable of both steady cost reduction and swift product variation adjustments.

Case Studies: Success Stories in Manufacturing

Case studies in manufacturing demonstrate that continuous improvement methodologies, such as Lean and Six Sigma, significantly enhance operational efficiency by reducing waste and streamlining processes. Agile manufacturing case studies highlight increased responsiveness to market changes and customer demands through flexible production systems and cross-functional teams. Companies integrating both approaches report higher productivity, faster product delivery, and improved quality, driving competitive advantage in dynamic industrial environments.

Choosing the Right Approach for Your Facility

Continuous Improvement emphasizes incremental, data-driven enhancements through methodologies like Lean and Six Sigma, optimizing existing processes for reduced waste and higher efficiency. Agile Manufacturing prioritizes flexibility and rapid response to market changes by integrating cross-functional teams and adaptive technologies to speed product development and customization. Selecting the right approach depends on your facility's operational goals, production complexity, and market volatility, balancing steady process optimization with the need for responsiveness and innovation.

Future Trends: Integrating Continuous Improvement and Agile Practices

Future trends in manufacturing emphasize the integration of continuous improvement methodologies like Lean and Six Sigma with agile manufacturing practices to enhance flexibility and efficiency. Advanced technologies such as IoT, AI, and machine learning enable real-time data analysis, facilitating rapid adaptation and ongoing process enhancements. This hybrid approach drives innovation, reduces waste, and accelerates product development cycles to meet evolving market demands.

Related Important Terms

Digital Kaizen

Digital Kaizen integrates continuous improvement principles with real-time data analytics to enhance manufacturing efficiency and quality. Agile manufacturing complements this by enabling rapid adaptation to market changes through flexible production processes and digital tools.

Agile Lean Integration

Agile Lean Integration combines Agile Manufacturing's adaptability with Lean principles' waste reduction to enhance production efficiency and responsiveness in dynamic markets. This approach aligns cross-functional teams and continuous feedback loops, driving iterative improvements while minimizing lead times and operational costs.

Continuous Flow Automation

Continuous Flow Automation enhances Continuous Improvement by maintaining a steady, uninterrupted production line that reduces waste and increases efficiency through real-time process monitoring and rapid feedback loops. Agile Manufacturing prioritizes flexibility and quick responsiveness but may introduce variability, whereas Continuous Flow Automation ensures consistent quality and throughput by standardizing workflows and minimizing downtime.

Sprint-based Production

Sprint-based production in agile manufacturing accelerates responsiveness to market changes by implementing short, iterative cycles that enable rapid prototyping and continuous feedback integration. In contrast, continuous improvement emphasizes incremental enhancements over longer periods, focusing on steady refinement of processes to increase efficiency and reduce waste systematically.

Kanban-Driven Iteration

Kanban-driven iteration in continuous improvement emphasizes visual workflow management and incremental enhancements to reduce waste and improve efficiency. Agile manufacturing leverages Kanban to enable rapid, flexible responses to market changes and customer demands through iterative production cycles.

Scalable Manufacturing Pods

Continuous improvement in manufacturing emphasizes incremental enhancements across existing workflows, while agile manufacturing enables rapid adaptability through modular, scalable manufacturing pods designed for flexibility and efficiency. Scalable manufacturing pods facilitate real-time reconfiguration and resource optimization, driving responsiveness to market changes and reducing production downtime in dynamic manufacturing environments.

Adaptive MES (Manufacturing Execution Systems)

Adaptive MES integrates real-time data and analytics to enable continuous improvement by optimizing workflows, reducing downtime, and enhancing production efficiency. Agile Manufacturing leverages Adaptive MES for flexible, rapid response to market changes and customization demands, fostering a dynamic, scalable production environment.

Hyperautomation Loop

Continuous Improvement in manufacturing emphasizes incremental process enhancements through data-driven analysis, while Agile Manufacturing prioritizes flexibility and rapid response to market changes using adaptive workflows. The Hyperautomation Loop integrates AI, machine learning, and robotic process automation to accelerate both Continuous Improvement cycles and Agile Manufacturing adaptability, driving efficiency and innovation at scale.

Real-Time Value Stream Mapping

Continuous Improvement employs systematic, ongoing enhancements by analyzing existing processes, while Agile Manufacturing emphasizes flexibility and rapid adaptation to market changes. Real-Time Value Stream Mapping integrates with both approaches by providing immediate visibility into production workflows, enabling faster identification and resolution of bottlenecks for optimized efficiency.

Flexible Cell Manufacturing

Flexible cell manufacturing enhances continuous improvement by enabling rapid reconfiguration of production cells to adapt to changing demands, reducing lead times and minimizing waste. Agile manufacturing leverages this flexibility to respond swiftly to market fluctuations, integrating cross-functional teams and real-time data analytics to optimize efficiency and product customization.

Continuous Improvement vs Agile Manufacturing Infographic

industrydif.com

industrydif.com