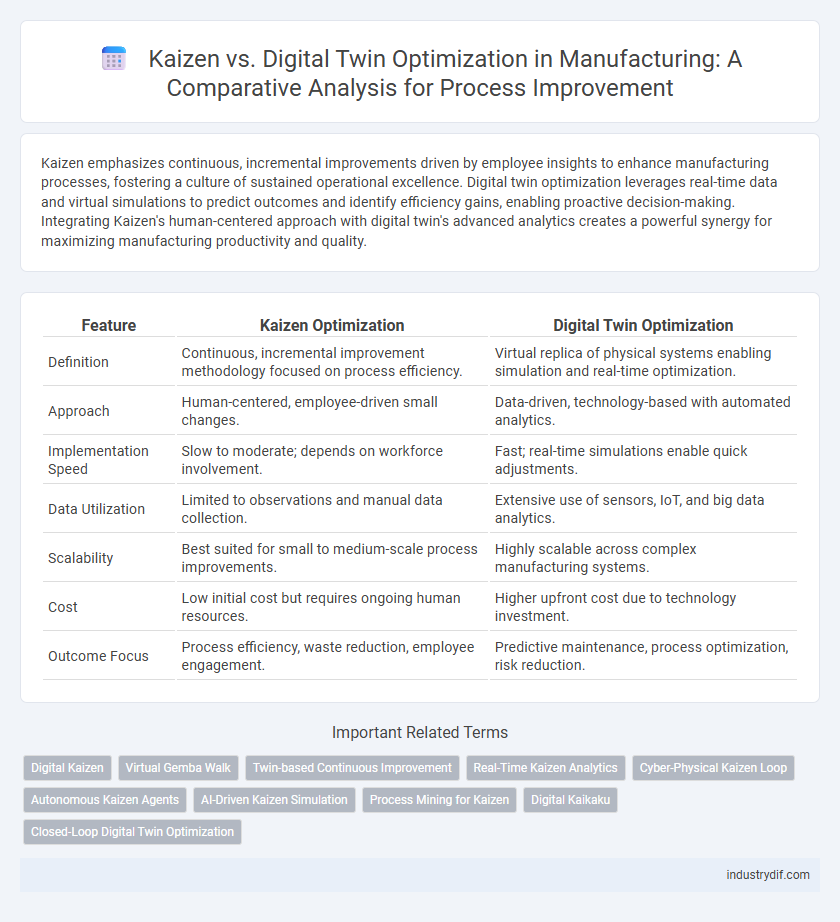

Kaizen emphasizes continuous, incremental improvements driven by employee insights to enhance manufacturing processes, fostering a culture of sustained operational excellence. Digital twin optimization leverages real-time data and virtual simulations to predict outcomes and identify efficiency gains, enabling proactive decision-making. Integrating Kaizen's human-centered approach with digital twin's advanced analytics creates a powerful synergy for maximizing manufacturing productivity and quality.

Table of Comparison

| Feature | Kaizen Optimization | Digital Twin Optimization |

|---|---|---|

| Definition | Continuous, incremental improvement methodology focused on process efficiency. | Virtual replica of physical systems enabling simulation and real-time optimization. |

| Approach | Human-centered, employee-driven small changes. | Data-driven, technology-based with automated analytics. |

| Implementation Speed | Slow to moderate; depends on workforce involvement. | Fast; real-time simulations enable quick adjustments. |

| Data Utilization | Limited to observations and manual data collection. | Extensive use of sensors, IoT, and big data analytics. |

| Scalability | Best suited for small to medium-scale process improvements. | Highly scalable across complex manufacturing systems. |

| Cost | Low initial cost but requires ongoing human resources. | Higher upfront cost due to technology investment. |

| Outcome Focus | Process efficiency, waste reduction, employee engagement. | Predictive maintenance, process optimization, risk reduction. |

Understanding Kaizen in Manufacturing

Kaizen in manufacturing emphasizes continuous, incremental improvements by engaging employees at all levels to enhance processes, reduce waste, and increase efficiency. It fosters a culture of teamwork and problem-solving through small, consistent adjustments rather than large-scale changes. This ongoing improvement methodology contrasts with Digital Twin Optimization, which uses virtual simulations and real-time data analytics to optimize manufacturing operations.

Introduction to Digital Twin Optimization

Digital Twin Optimization leverages real-time data and advanced simulation models to create a virtual replica of physical manufacturing processes, enabling precise performance analysis and predictive maintenance. This technology enhances operational efficiency by identifying bottlenecks, forecasting equipment failures, and optimizing production workflows with data-driven insights. Compared to traditional Kaizen methods focusing on continuous incremental improvements, Digital Twin Optimization offers dynamic, scalable solutions for complex manufacturing environments.

Key Principles of Continuous Improvement

Kaizen emphasizes incremental, continuous improvements driven by employee involvement and standardized work to eliminate waste and enhance efficiency. Digital Twin Optimization leverages real-time data and simulation models to predict performance and optimize operations dynamically. Both approaches prioritize iterative refinement but differ in methodology--Kaizen relies on human-centric processes, while Digital Twin uses advanced digital technologies for proactive decision-making.

Digital Twins: Technology and Application

Digital Twin technology in manufacturing leverages real-time data and simulation models to create a virtual replica of physical assets, enabling enhanced process optimization and predictive maintenance. By integrating IoT sensors and AI analytics, Digital Twins provide actionable insights that minimize downtime, improve production efficiency, and reduce operational costs. This technology facilitates scenario testing and informed decision-making, accelerating continuous improvement beyond traditional Kaizen methods.

Benefits of Kaizen for Operational Efficiency

Kaizen drives continuous improvement by empowering employees to identify inefficiencies and implement small, incremental changes that enhance operational workflows. This approach fosters a culture of ongoing collaboration and waste reduction, leading to sustained cost savings and productivity gains. Its emphasis on real-time problem-solving and incremental adjustments ensures long-term operational efficiency without significant capital investment.

Digital Twin’s Role in Process Optimization

Digital Twin technology plays a crucial role in process optimization by creating real-time virtual replicas of manufacturing systems, enabling precise monitoring and predictive analysis. It facilitates data-driven decision-making through simulations that identify inefficiencies and test improvements without disrupting production lines. Integrating Digital Twins accelerates continuous improvement, reduces downtime, and enhances overall operational efficiency beyond traditional Kaizen methodologies.

Integrating Kaizen with Smart Manufacturing

Integrating Kaizen with smart manufacturing leverages continuous improvement principles alongside advanced digital twin technology to optimize production processes in real-time. Digital twins enable detailed simulation and data analysis, facilitating rapid identification of inefficiencies that Kaizen methodologies systematically address through incremental changes. This synergy enhances operational agility, reduces downtime, and drives sustainable manufacturing performance improvements.

Comparing Traditional Improvement vs. Digital Optimization

Kaizen emphasizes continuous, incremental improvements driven by employee involvement and lean manufacturing principles, fostering a culture of gradual efficiency gains. Digital Twin Optimization utilizes real-time data and simulation models to create digital replicas of physical processes, enabling rapid scenario testing and predictive analysis for precise operational adjustments. While Kaizen relies on human insight and iterative change, Digital Twin offers automated, data-driven optimization, accelerating decision-making and minimizing downtime in manufacturing.

Challenges in Adopting Kaizen and Digital Twins

Challenges in adopting Kaizen in manufacturing include resistance to cultural change, inconsistent staff engagement, and difficulty sustaining continuous improvement initiatives. Digital Twin Optimization faces hurdles such as high implementation costs, complex integration with legacy systems, and the need for advanced data analytics expertise. Both approaches require overcoming technological and organizational barriers to realize their full potential in operational efficiency enhancement.

Future Trends: Synergizing Kaizen and Digital Twin Strategies

Future manufacturing trends emphasize the integration of Kaizen's continuous improvement principles with Digital Twin technology's real-time data simulation, enabling more dynamic and adaptive production processes. Leveraging Digital Twins for predictive analytics enhances Kaizen-driven incremental changes by providing precise, actionable insights into equipment performance and process inefficiencies. This synergy fosters smarter decision-making, reduces downtime, and accelerates innovation cycles within smart factories.

Related Important Terms

Digital Kaizen

Digital Kaizen integrates continuous improvement principles with advanced digital technologies, enabling real-time process monitoring and data-driven decision-making to enhance manufacturing efficiency. Unlike traditional Kaizen, Digital Kaizen leverages digital twin optimization to simulate, analyze, and refine production workflows, resulting in faster identification of inefficiencies and higher productivity gains.

Virtual Gemba Walk

Kaizen emphasizes continuous, incremental improvements through on-site employee collaboration, while Digital Twin Optimization leverages virtual models for real-time simulation and predictive analytics, enhancing decision-making efficiency. Virtual Gemba Walks integrate these approaches by enabling remote, data-driven observations of manufacturing processes, facilitating faster identification of bottlenecks and process inefficiencies.

Twin-based Continuous Improvement

Digital Twin Optimization leverages real-time data and simulation models to enable precise monitoring and predictive analysis, enhancing manufacturing processes through continuous feedback loops. Kaizen focuses on incremental human-driven improvements, while twin-based continuous improvement integrates digital twin technology to accelerate decision-making, increase operational efficiency, and reduce downtime in production environments.

Real-Time Kaizen Analytics

Real-Time Kaizen Analytics leverages continuous improvement methodologies by integrating live data streams to identify inefficiencies and implement immediate operational adjustments. Unlike Digital Twin Optimization, which simulates processes virtually, real-time Kaizen emphasizes actionable insights directly derived from ongoing manufacturing activities to drive incremental performance enhancements.

Cyber-Physical Kaizen Loop

The Cyber-Physical Kaizen Loop integrates Kaizen's continuous improvement principles with Digital Twin optimization by enabling real-time data exchange between physical manufacturing systems and their virtual counterparts to enhance operational efficiency. This loop allows for iterative process adjustments through predictive analytics and simulation, driving proactive defect reduction and resource optimization in smart factories.

Autonomous Kaizen Agents

Autonomous Kaizen Agents leverage real-time data integration and AI-driven analytics to continuously identify and implement incremental improvements, enhancing production efficiency and reducing waste more dynamically than traditional Kaizen methods. Digital Twin Optimization complements this by creating virtual replicas of manufacturing systems, enabling simulation-driven decision-making that accelerates autonomous process refinement and predictive maintenance.

AI-Driven Kaizen Simulation

AI-driven Kaizen simulation leverages machine learning algorithms to continuously analyze manufacturing processes, enabling real-time identification and elimination of inefficiencies for enhanced operational performance. Digital twin optimization creates a virtual replica of the manufacturing environment, allowing predictive analytics and scenario testing that complement Kaizen's incremental improvement approach through data-driven insights.

Process Mining for Kaizen

Kaizen leverages process mining to identify inefficiencies and continuous improvement opportunities by analyzing real-time data from manufacturing workflows, enabling incremental process enhancements. Digital Twin Optimization creates a virtual replica of manufacturing systems to simulate and predict outcomes, but process mining in Kaizen directly uncovers hidden process bottlenecks and waste for actionable improvements.

Digital Kaikaku

Digital Kaikaku integrates the continuous improvement principles of Kaizen with advanced Digital Twin Optimization, enabling manufacturers to simulate, analyze, and implement transformative changes rapidly. This approach accelerates operational efficiency and innovation by leveraging real-time digital replicas and data-driven insights to drive systemic process breakthroughs beyond incremental improvements.

Closed-Loop Digital Twin Optimization

Closed-Loop Digital Twin Optimization leverages real-time data feedback to continuously refine manufacturing processes, enabling dynamic adjustments that enhance productivity and reduce downtime more effectively than traditional Kaizen methods. By integrating sensor data and predictive analytics, Closed-Loop Digital Twins create a self-adaptive system that optimizes manufacturing operations with precision and agility.

Kaizen vs Digital Twin Optimization Infographic

industrydif.com

industrydif.com