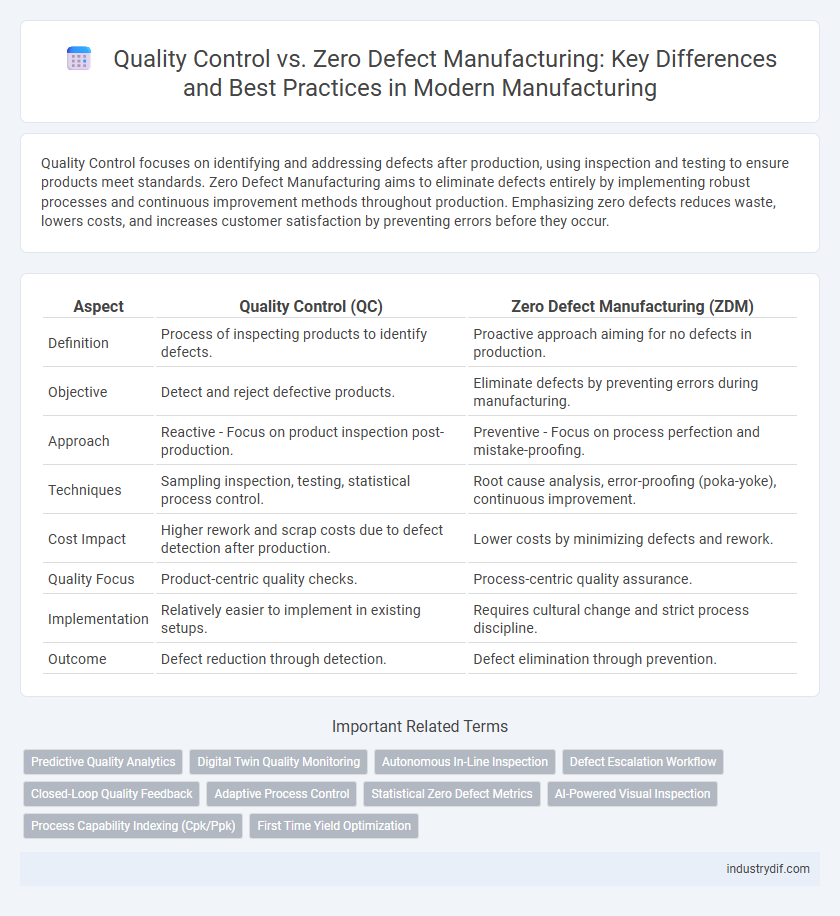

Quality Control focuses on identifying and addressing defects after production, using inspection and testing to ensure products meet standards. Zero Defect Manufacturing aims to eliminate defects entirely by implementing robust processes and continuous improvement methods throughout production. Emphasizing zero defects reduces waste, lowers costs, and increases customer satisfaction by preventing errors before they occur.

Table of Comparison

| Aspect | Quality Control (QC) | Zero Defect Manufacturing (ZDM) |

|---|---|---|

| Definition | Process of inspecting products to identify defects. | Proactive approach aiming for no defects in production. |

| Objective | Detect and reject defective products. | Eliminate defects by preventing errors during manufacturing. |

| Approach | Reactive - Focus on product inspection post-production. | Preventive - Focus on process perfection and mistake-proofing. |

| Techniques | Sampling inspection, testing, statistical process control. | Root cause analysis, error-proofing (poka-yoke), continuous improvement. |

| Cost Impact | Higher rework and scrap costs due to defect detection after production. | Lower costs by minimizing defects and rework. |

| Quality Focus | Product-centric quality checks. | Process-centric quality assurance. |

| Implementation | Relatively easier to implement in existing setups. | Requires cultural change and strict process discipline. |

| Outcome | Defect reduction through detection. | Defect elimination through prevention. |

Introduction to Quality Control and Zero Defect Manufacturing

Quality Control (QC) involves systematic inspection and testing of products to ensure they meet predefined quality standards, reducing defects through detection and correction. Zero Defect Manufacturing (ZDM) emphasizes defect prevention by integrating quality into every stage of the production process, striving for flawless output and eliminating rework. Both approaches aim to enhance product reliability and customer satisfaction but differ in methodology--QC focuses on identifying defects, while ZDM prioritizes their complete eradication.

Defining Quality Control in Manufacturing

Quality Control in manufacturing involves systematic processes to monitor and evaluate product quality against established standards, ensuring that defects are identified and corrected promptly. It relies on inspection, testing, and statistical analysis to maintain consistency and compliance throughout production. This approach aims to reduce variability and prevent defective products from reaching customers, enhancing overall reliability and satisfaction.

What is Zero Defect Manufacturing?

Zero Defect Manufacturing (ZDM) is a quality management strategy aimed at eliminating defects in the production process by emphasizing prevention rather than detection. It focuses on designing processes and systems that consistently produce products without errors, using techniques such as statistical process control, employee training, and continuous improvement. Implementing ZDM reduces waste, lowers costs, and enhances customer satisfaction by ensuring products meet strict quality standards from the outset.

Core Principles: Quality Control vs Zero Defect

Quality Control focuses on detecting and correcting defects through systematic inspections and testing during the manufacturing process, ensuring products meet predefined standards. In contrast, Zero Defect Manufacturing emphasizes defect prevention by embedding quality into every stage, aiming for continuous process improvement and error-free production. The core principle of Quality Control is reactive defect management, while Zero Defect prioritizes proactive defect elimination to achieve optimal product quality.

Process Implementation: QC vs Zero Defect Approaches

Quality Control (QC) focuses on identifying and correcting defects through inspections and testing after production stages, emphasizing defect detection rather than prevention. Zero Defect Manufacturing (ZDM) adopts a proactive approach by integrating error-proofing techniques, rigorous process design, and continuous monitoring to eliminate defects throughout the entire production process. Implementing ZDM requires a cultural shift toward process perfection and operator involvement, reducing reliance on end-line QC and significantly enhancing overall product quality.

Benefits of Quality Control in Manufacturing

Quality control in manufacturing ensures consistent product standards by detecting defects early, reducing waste and rework costs significantly. It enhances customer satisfaction and brand reputation through reliable product performance and compliance with industry regulations. Implementing quality control systems like Statistical Process Control (SPC) improves process efficiency and facilitates continuous improvement initiatives.

Advantages of Zero Defect Manufacturing

Zero Defect Manufacturing (ZDM) significantly reduces product defects by emphasizing prevention rather than detection, leading to higher overall product quality and customer satisfaction. Unlike traditional Quality Control (QC) that identifies defects post-production, ZDM integrates real-time monitoring and continuous improvement throughout the manufacturing process, minimizing waste and operational costs. Implementing ZDM enhances process reliability, boosts supplier consistency, and strengthens compliance with industry standards, resulting in measurable productivity gains.

Challenges and Limitations of Each Method

Quality control primarily addresses defects through inspection and testing, which can result in increased time and costs due to rework and waste. Zero defect manufacturing aims to eliminate errors at the source, but its implementation demands significant investment in advanced technology and extensive employee training. Both approaches face challenges where quality control struggles with detecting all defects, while zero defect manufacturing faces limitations in adaptability and scalability across complex production environments.

Impact on Production Cost and Efficiency

Quality Control ensures product standards through inspection and testing, which often increases production costs and reduces efficiency due to rework and scrap. Zero Defect Manufacturing aims to eliminate defects during the production process, minimizing waste and lowering costs by preventing errors upfront. Implementing Zero Defect strategies significantly enhances overall operational efficiency and reduces the total cost of production compared to traditional Quality Control methods.

Choosing the Right Approach for Your Facility

Quality control focuses on detecting and correcting defects during or after production, ensuring products meet specified standards through inspection and testing processes. Zero Defect Manufacturing emphasizes proactive prevention by integrating defect-free processes and continuous improvement to eliminate errors from the outset. Selecting the right approach depends on facility capabilities, production complexity, and quality goals, balancing inspection efforts with process optimization for sustainable manufacturing excellence.

Related Important Terms

Predictive Quality Analytics

Predictive quality analytics leverages real-time data and machine learning algorithms to identify potential defects before they occur, enhancing the effectiveness of both Quality Control and Zero Defect Manufacturing strategies. This approach reduces production downtime and waste by enabling proactive decision-making, ultimately driving higher product reliability and customer satisfaction.

Digital Twin Quality Monitoring

Digital Twin Quality Monitoring enhances Quality Control by providing real-time virtual replicas of manufacturing processes, enabling early defect detection and process optimization. This technology supports Zero Defect Manufacturing goals by continuously simulating and analyzing production variables to prevent faults before physical defects occur.

Autonomous In-Line Inspection

Autonomous In-Line Inspection integrates advanced AI and machine vision to enhance Quality Control by detecting defects in real-time, minimizing human error and production downtime. Zero Defect Manufacturing relies on these precise, continuous inspections to achieve near-perfect product standards, reducing waste and boosting operational efficiency.

Defect Escalation Workflow

Quality Control typically involves identifying and segregating defective products, triggering a defect escalation workflow that prioritizes immediate containment and root cause analysis to prevent recurrence. Zero Defect Manufacturing aims to eliminate defects at the source by integrating real-time monitoring and automated feedback loops within the escalation workflow, reducing production disruptions and enhancing overall process reliability.

Closed-Loop Quality Feedback

Closed-loop quality feedback in manufacturing integrates real-time data collection and analysis to identify defects promptly, enabling immediate corrective actions that enhance overall product quality. Zero Defect Manufacturing leverages this feedback system to minimize variability and systematically eliminate defects, ensuring consistent adherence to quality standards throughout the production process.

Adaptive Process Control

Adaptive Process Control enhances Quality Control by continuously monitoring production parameters to reduce variations and defects, aligning closely with the principles of Zero Defect Manufacturing. This approach leverages real-time data analytics and machine learning algorithms to dynamically adjust processes, minimizing errors and achieving consistent product quality.

Statistical Zero Defect Metrics

Statistical zero defect metrics emphasize reducing variability and defects through data-driven quality control techniques, aiming for near-perfect production processes. Unlike traditional quality control, which often relies on inspection and corrective actions, zero defect manufacturing utilizes real-time statistical analysis to prevent defects before they occur, increasing overall efficiency and product reliability.

AI-Powered Visual Inspection

AI-powered visual inspection enhances quality control in manufacturing by enabling real-time defect detection and reducing human errors, thus improving overall product reliability. Integrating this technology supports zero defect manufacturing objectives through precise identification and elimination of faults at every production stage.

Process Capability Indexing (Cpk/Ppk)

Process Capability Indexing (Cpk/Ppk) serves as a critical metric in Quality Control to evaluate the consistency and predictability of manufacturing processes, ensuring products meet specification limits. Zero Defect Manufacturing emphasizes achieving near-perfect Cpk/Ppk values to minimize variability and eliminate defects, fostering a culture of continuous improvement and operational excellence.

First Time Yield Optimization

Quality control focuses on identifying and reducing defects through inspection and testing, while zero defect manufacturing aims to eliminate defects entirely by designing processes that produce flawless products from the start. First Time Yield optimization is critical in zero defect manufacturing as it measures the percentage of products made correctly without rework, driving efficiency and minimizing waste.

Quality Control vs Zero Defect Manufacturing Infographic

industrydif.com

industrydif.com