Smart factories leverage advanced IoT sensors, AI, and real-time data analytics to optimize production efficiency and enable proactive maintenance. Dark factories operate with minimal or no human presence by fully automating processes, reducing labor costs, and enabling continuous 24/7 production. Both concepts enhance manufacturing productivity but differ in human involvement and automation levels.

Table of Comparison

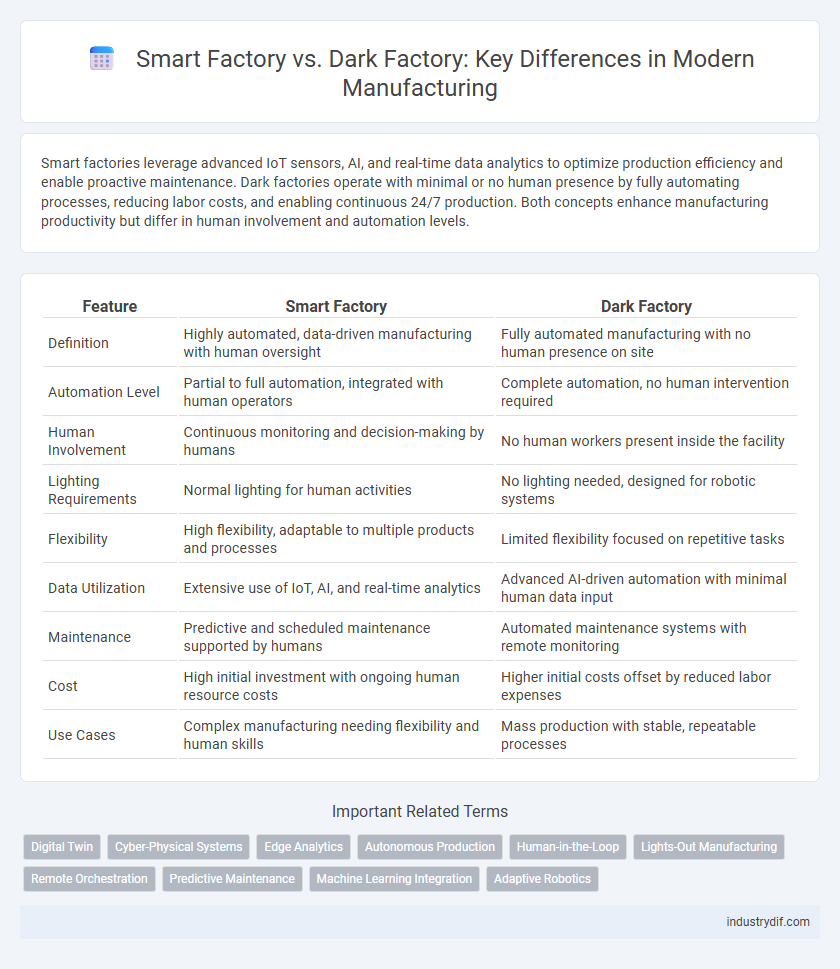

| Feature | Smart Factory | Dark Factory |

|---|---|---|

| Definition | Highly automated, data-driven manufacturing with human oversight | Fully automated manufacturing with no human presence on site |

| Automation Level | Partial to full automation, integrated with human operators | Complete automation, no human intervention required |

| Human Involvement | Continuous monitoring and decision-making by humans | No human workers present inside the facility |

| Lighting Requirements | Normal lighting for human activities | No lighting needed, designed for robotic systems |

| Flexibility | High flexibility, adaptable to multiple products and processes | Limited flexibility focused on repetitive tasks |

| Data Utilization | Extensive use of IoT, AI, and real-time analytics | Advanced AI-driven automation with minimal human data input |

| Maintenance | Predictive and scheduled maintenance supported by humans | Automated maintenance systems with remote monitoring |

| Cost | High initial investment with ongoing human resource costs | Higher initial costs offset by reduced labor expenses |

| Use Cases | Complex manufacturing needing flexibility and human skills | Mass production with stable, repeatable processes |

Introduction to Smart Factory and Dark Factory

Smart factories leverage advanced technologies such as IoT, AI, and robotics to enable real-time data exchange, automated decision-making, and flexible production processes, resulting in increased efficiency and reduced operational costs. Dark factories operate with minimal or no human presence, relying heavily on fully automated systems and machine-to-machine communication to maintain continuous manufacturing without daytime lighting. Both concepts represent significant advancements in Industry 4.0, aiming to optimize production through digital transformation and automation.

Key Differences Between Smart and Dark Factories

Smart factories integrate advanced IoT sensors, AI-driven analytics, and human-machine interfaces to enable real-time decision-making and flexible production processes, enhancing operational efficiency and customization. Dark factories operate fully autonomously without human presence, relying on robotics and automated systems for continuous, 24/7 manufacturing, significantly reducing labor costs and minimizing human error. Key differences include the presence of human oversight in smart factories, adaptability in manufacturing tasks, and the fully automated, human-free environment characteristic of dark factories.

Core Technologies Powering Smart Factories

Smart factories leverage core technologies such as IoT sensors, artificial intelligence, and real-time data analytics to optimize production efficiency and enable predictive maintenance. Unlike dark factories, which operate without human presence primarily through automation and robotics, smart factories integrate human-machine collaboration supported by advanced digital twins and connectivity platforms. These technologies drive agility, enhance decision-making, and foster continuous improvement in manufacturing processes.

Automation and Robotics in Dark Factories

Dark factories utilize advanced automation and robotics to achieve fully autonomous manufacturing processes, minimizing human intervention and maximizing efficiency. These facilities rely on AI-driven robots for continuous operation, precision, and real-time data analytics to optimize production workflows. The integration of automated guided vehicles (AGVs) and robotic arms enables consistent output quality and reduces operational costs in dark factory environments.

Human Roles: Smart Factories vs Dark Factories

Smart factories integrate human roles with advanced AI and IoT technologies, enabling operators to monitor processes, make real-time decisions, and optimize production efficiency. In contrast, dark factories operate fully autonomously without human presence on-site, relying solely on robotics and automated systems for continuous manufacturing. This shift significantly reduces direct human involvement but increases the demand for remote monitoring, system maintenance, and AI oversight roles.

Energy Efficiency and Sustainability

Smart factories leverage IoT sensors and AI-driven analytics to optimize energy consumption, significantly reducing waste and lowering carbon emissions. Dark factories operate autonomously without human presence, enabling continuous production and energy savings by minimizing lighting and HVAC usage. Both models enhance sustainability by integrating advanced control systems for precise energy management and resource utilization.

Operational Efficiency and Productivity

Smart factories leverage IoT sensors, AI analytics, and real-time data to optimize workflows, reduce downtime, and enhance operational efficiency, resulting in higher productivity rates. Dark factories operate fully automated manufacturing processes without human intervention, enabling continuous 24/7 production with minimal errors and energy consumption. Both systems improve productivity, but smart factories offer greater flexibility and adaptive optimization, while dark factories prioritize cost savings and consistent output.

Challenges and Limitations of Each Approach

Smart factories face challenges in integrating complex IoT systems and ensuring cybersecurity across interconnected devices, leading to potential vulnerabilities and high implementation costs. Dark factories, which operate fully automated without human presence, struggle with limited flexibility in handling unexpected scenarios and require substantial upfront investment in advanced robotics and AI. Both approaches face limitations in scalability and adaptability to diverse manufacturing environments, impacting overall efficiency and reliability.

Future Trends in Factory Automation

Smart factories leverage IoT sensors, AI-driven analytics, and real-time data integration to optimize production efficiency and predictive maintenance. Dark factories operate autonomously without human presence, utilizing robotics and AI to achieve uninterrupted 24/7 manufacturing with minimal errors. Future trends in factory automation emphasize increased digital twin applications, advanced machine learning for quality control, and the integration of edge computing to enhance responsiveness and reduce latency in industrial environments.

Choosing the Right Factory Model for Your Business

Choosing the right factory model involves evaluating operational goals, workforce availability, and technology integration levels. Smart factories leverage IoT, AI, and real-time data analytics to optimize production efficiency while maintaining human oversight. Dark factories eliminate the need for on-site personnel by using fully automated systems, ideal for businesses prioritizing 24/7 operation with minimal human intervention.

Related Important Terms

Digital Twin

Smart factories leverage digital twin technology to simulate, monitor, and optimize production processes in real-time, enhancing operational efficiency and predictive maintenance. Dark factories operate autonomously without human presence, relying heavily on digital twins to enable seamless automation and minimize downtime through precise virtual replication of physical assets.

Cyber-Physical Systems

Cyber-Physical Systems (CPS) in Smart Factories integrate real-time data analytics and connected devices to optimize production, enhance flexibility, and enable autonomous decision-making. In contrast, Dark Factories leverage CPS for fully automated, human-free operations, maximizing efficiency and minimizing errors through continuous machine-to-machine communication and remote monitoring.

Edge Analytics

Smart factories leverage edge analytics to process real-time data from connected machines, enhancing predictive maintenance and production efficiency. In contrast, dark factories rely heavily on edge analytics for autonomous operations without human intervention, maximizing continuous output and minimizing downtime.

Autonomous Production

Smart factories leverage interconnected IoT devices, AI-driven robotics, and real-time data analytics to enable flexible, automated production processes with minimal human intervention. Dark factories operate entirely autonomously, running 24/7 without any onsite personnel by utilizing advanced robotics and AI systems for self-monitoring and maintenance, maximizing efficiency and reducing labor costs.

Human-in-the-Loop

Smart factories integrate Human-in-the-Loop systems enabling real-time decision-making, adaptive automation, and collaborative robotics to optimize production efficiency and quality. Dark factories operate fully autonomously without human intervention, relying on AI, sensors, and robotics to maintain continuous operations but lack the flexibility and contextual judgment provided by human oversight.

Lights-Out Manufacturing

Lights-out manufacturing in smart factories leverages advanced automation, IoT sensors, and AI-driven analytics to operate without human presence, increasing efficiency and reducing errors. Dark factories exemplify this concept by running fully autonomous production lines 24/7, minimizing operational costs and maximizing throughput through real-time data monitoring and adaptive robotics.

Remote Orchestration

Smart factories utilize advanced IoT sensors and AI-driven analytics to enable real-time remote orchestration of manufacturing processes, enhancing efficiency and predictive maintenance. Dark factories operate autonomously with minimal human intervention, relying heavily on remote orchestration systems to monitor, control, and optimize production in environments devoid of direct on-site supervision.

Predictive Maintenance

Smart factories utilize IoT sensors and AI-driven analytics to enable predictive maintenance, reducing downtime by forecasting equipment failures before they occur. Dark factories operate fully automated production lines without human presence, relying heavily on predictive maintenance algorithms to ensure continuous, uninterrupted operation.

Machine Learning Integration

Smart factories harness machine learning integration to optimize real-time data analytics, predictive maintenance, and adaptive process controls, significantly enhancing operational efficiency and reducing downtime. In contrast, dark factories rely heavily on automated systems without human intervention but lack the advanced machine learning algorithms that enable dynamic decision-making and continuous process improvement.

Adaptive Robotics

Adaptive robotics in smart factories enable real-time decision-making and flexible automation through advanced sensors and AI integration, enhancing productivity and customization. In contrast, dark factories utilize adaptive robotics for fully autonomous, lights-out operations, maximizing efficiency by operating without human intervention in controlled environments.

Smart Factory vs Dark Factory Infographic

industrydif.com

industrydif.com