Smart Factory integrates advanced IoT sensors and AI-driven data analytics to enhance production efficiency and enable real-time decision-making. Hyperautomation extends this by combining AI, machine learning, and robotic process automation to streamline complex workflows across the entire manufacturing lifecycle. Leveraging both technologies results in optimized operational performance, reduced downtime, and increased scalability.

Table of Comparison

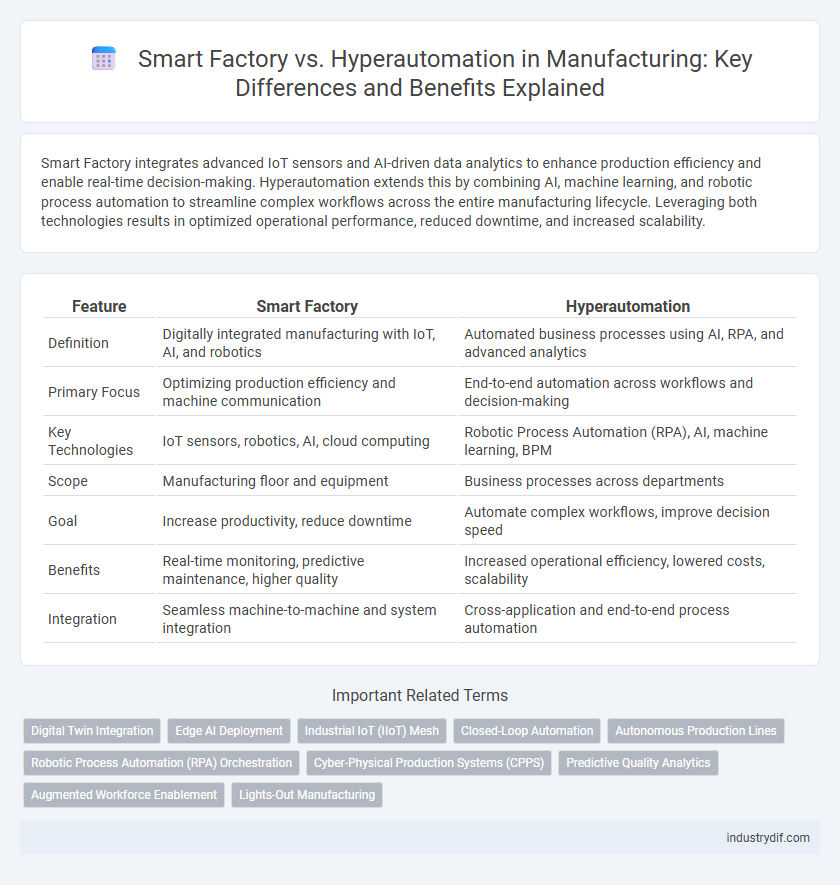

| Feature | Smart Factory | Hyperautomation |

|---|---|---|

| Definition | Digitally integrated manufacturing with IoT, AI, and robotics | Automated business processes using AI, RPA, and advanced analytics |

| Primary Focus | Optimizing production efficiency and machine communication | End-to-end automation across workflows and decision-making |

| Key Technologies | IoT sensors, robotics, AI, cloud computing | Robotic Process Automation (RPA), AI, machine learning, BPM |

| Scope | Manufacturing floor and equipment | Business processes across departments |

| Goal | Increase productivity, reduce downtime | Automate complex workflows, improve decision speed |

| Benefits | Real-time monitoring, predictive maintenance, higher quality | Increased operational efficiency, lowered costs, scalability |

| Integration | Seamless machine-to-machine and system integration | Cross-application and end-to-end process automation |

Introduction to Smart Factory and Hyperautomation

Smart Factory integrates IoT devices, AI, and advanced robotics to create automated, data-driven manufacturing processes that enhance efficiency and flexibility. Hyperautomation expands on these principles by combining AI, machine learning, and RPA (Robotic Process Automation) to automate complex workflows beyond traditional automation capabilities. Both technologies drive Industry 4.0 transformations but differ in scope, with Smart Factory concentrating on physical production optimization and Hyperautomation focusing on end-to-end process automation.

Defining Smart Factory: Core Concepts

A Smart Factory integrates advanced sensors, IoT devices, and AI-driven analytics to optimize manufacturing processes, ensuring real-time data visibility and adaptive production control. Core concepts include cyber-physical systems, digital twins, and interconnected machinery that enable predictive maintenance and energy efficiency. This foundational framework promotes autonomous decision-making and seamless integration of supply chain operations.

What is Hyperautomation? Key Features

Hyperautomation in manufacturing refers to the use of advanced technologies such as artificial intelligence, machine learning, robotic process automation (RPA), and data analytics to automate complex business processes and workflows beyond traditional automation capabilities. Key features of hyperautomation include end-to-end process automation, integration of multiple automation tools, real-time data analysis for decision-making, and continuous process optimization to enhance operational efficiency and reduce human error. This approach enables smart factories to achieve higher productivity, agility, and scalability by automating both routine and strategic tasks.

Technological Foundations: IoT, AI, and Robotics

Smart Factory leverages IoT sensors for real-time data acquisition, AI for predictive analytics, and robotics to automate assembly lines, enhancing production efficiency. Hyperautomation builds on these technologies by integrating advanced AI algorithms, IoT devices, and robotics with process mining and low-code platforms to automate complex workflows end-to-end. The convergence of IoT, AI, and robotics establishes the technological foundation enabling seamless digital transformation in modern manufacturing environments.

Differences Between Smart Factory and Hyperautomation

Smart Factory integrates IoT, AI, and robotics to create an interconnected manufacturing environment focused on real-time data analytics and adaptive processes. Hyperautomation emphasizes combining multiple automation technologies like AI, RPA, and machine learning to automate complex workflows beyond physical production. While Smart Factory centers on optimizing factory operations through intelligent systems, Hyperautomation targets end-to-end process automation across the entire manufacturing value chain.

Integration Challenges in Modern Manufacturing

Integration challenges in modern manufacturing arise from the complexity of connecting diverse systems within smart factories and hyperautomation environments. Smart factories rely on IoT devices, AI-driven analytics, and cyber-physical systems, which often face interoperability issues due to varied protocols and legacy equipment. Hyperautomation intensifies these challenges by combining robotic process automation (RPA), machine learning, and digital twins, demanding seamless data flow and real-time synchronization across heterogeneous platforms.

Business Benefits: Efficiency, Flexibility, and Scalability

Smart Factory integrates advanced IoT devices and real-time data analytics to optimize manufacturing efficiency by reducing downtime and enhancing predictive maintenance. Hyperautomation leverages AI-driven processes and robotic process automation (RPA) to increase operational flexibility, enabling rapid adaptation to changing production demands. Both technologies drive scalability by facilitating seamless integration of new tools and workflows, supporting accelerated growth and cost reduction in manufacturing workflows.

Implementation Strategies for Factories

Smart Factory implementation relies on integrating IoT sensors, AI-driven analytics, and real-time data management to optimize production workflows and enhance equipment efficiency. Hyperautomation strategies focus on combining robotic process automation (RPA), machine learning, and advanced AI to automate complex decision-making and reduce manual interventions across manufacturing operations. Factories adopting these technologies prioritize scalable infrastructure, cross-functional collaboration, and continuous monitoring to ensure seamless integration and performance improvement.

Case Studies: Real-World Industry Applications

Case studies reveal smart factories use IoT sensors and AI to enhance real-time production monitoring and quality control, improving efficiency and reducing downtime. Hyperautomation integrates advanced RPA, machine learning, and analytics to automate complex workflows, enabling faster decision-making and supply chain optimization. Industries like automotive and electronics report up to 30% productivity gains and 25% cost reductions through these technologies.

Future Trends in Manufacturing Automation

Smart Factory technology integrates IoT sensors, AI-driven analytics, and robotics to enhance real-time decision-making and operational efficiency in manufacturing. Hyperautomation expands on this by leveraging advanced AI, machine learning, and robotic process automation (RPA) to automate complex end-to-end workflows across multiple systems. Future trends indicate a convergence of Smart Factory frameworks with hyperautomation platforms, driving unprecedented levels of agility, predictive maintenance, and adaptive production processes.

Related Important Terms

Digital Twin Integration

Smart Factory leverages IoT sensors and machine learning to create dynamic digital twins that optimize production efficiency, while hyperautomation integrates AI-driven workflows and robotic process automation to enhance decision-making and operational agility. Digital twin integration in smart factories provides real-time simulation and predictive analytics, enabling hyperautomation systems to execute complex manufacturing tasks with precision and reduced downtime.

Edge AI Deployment

Smart factories leverage Edge AI deployment to enable real-time data processing and adaptive manufacturing workflows, enhancing operational efficiency and reducing latency. Hyperautomation integrates Edge AI with advanced process automation tools, accelerating decision-making and predictive maintenance across distributed manufacturing environments.

Industrial IoT (IIoT) Mesh

Industrial IoT (IIoT) Mesh enhances Smart Factory environments by enabling seamless, decentralized connectivity between machines, sensors, and systems, optimizing real-time data exchange and operational efficiency. Hyperautomation leverages this IIoT Mesh infrastructure to integrate advanced AI, robotics, and automation workflows, driving fully autonomous manufacturing processes and minimizing human intervention.

Closed-Loop Automation

Smart Factory integrates IoT sensors and real-time data analytics to enhance production efficiency, while Hyperautomation leverages AI and machine learning to automate complex workflows, driving Closed-Loop Automation that continuously monitors and optimizes manufacturing processes without human intervention. This seamless feedback system adjusts operations instantly based on incoming data, reducing downtime and improving product quality in dynamic industrial environments.

Autonomous Production Lines

Smart factories integrate IoT, AI, and data analytics to optimize operations, while hyperautomation extends automation by combining these technologies with robotic process automation (RPA) and machine learning for fully autonomous production lines. Autonomous production lines leverage hyperautomation to enable real-time decision-making, predictive maintenance, and adaptive workflows, significantly reducing downtime and increasing manufacturing efficiency.

Robotic Process Automation (RPA) Orchestration

Smart Factory leverages integrated Cyber-Physical Systems and IoT sensors for real-time data exchange and process optimization, while Hyperautomation emphasizes Robotic Process Automation (RPA) orchestration to automate complex workflows across multiple systems. RPA orchestration in Hyperautomation enables seamless coordination of bots for end-to-end process automation, reducing manual intervention and enhancing operational agility in manufacturing environments.

Cyber-Physical Production Systems (CPPS)

Smart Factories leverage Cyber-Physical Production Systems (CPPS) to integrate physical machinery with digital control systems, enabling real-time data exchange and adaptive manufacturing processes. Hyperautomation extends this by employing advanced AI, machine learning, and robotic process automation to autonomously optimize CPPS workflows, enhancing efficiency and reducing human intervention.

Predictive Quality Analytics

Predictive Quality Analytics in smart factories leverages IoT sensors and machine learning algorithms to monitor real-time production metrics and detect anomalies before defects occur. Hyperautomation enhances this by integrating AI-driven process optimization tools and robotic process automation, enabling seamless end-to-end quality control and adaptive manufacturing workflows.

Augmented Workforce Enablement

Smart Factory integrates IoT, AI, and robotics to enhance production efficiency, while Hyperautomation extends this by combining AI, machine learning, and automation tools to empower the augmented workforce with real-time data insights and adaptive decision-making capabilities. Augmented workforce enablement leverages wearable technology, collaborative robots (cobots), and intelligent workflows to improve worker productivity and safety in dynamic manufacturing environments.

Lights-Out Manufacturing

Smart Factory integrates IoT sensors and real-time analytics to enhance flexibility and efficiency, while Hyperautomation leverages AI-driven robotic process automation (RPA) to enable fully autonomous operations, crucial for achieving Lights-Out Manufacturing. Lights-Out Manufacturing depends on seamless hyperautomation to minimize human intervention, optimize production throughput, and reduce operational costs in Industry 4.0 environments.

Smart Factory vs Hyperautomation Infographic

industrydif.com

industrydif.com