Additive manufacturing enables the creation of complex, customized parts layer by layer, reducing material waste and shortening production cycles. Distributed manufacturing leverages decentralized production facilities, minimizing logistics costs and improving responsiveness to local demand. Together, these approaches revolutionize the manufacturing landscape by enhancing flexibility and scalability.

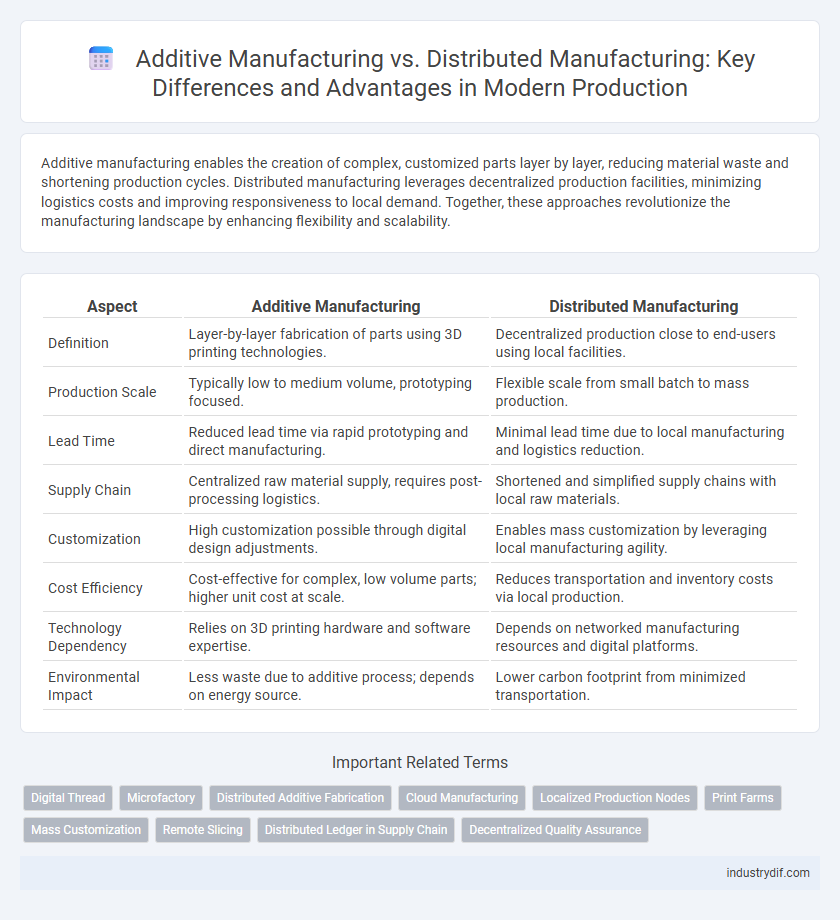

Table of Comparison

| Aspect | Additive Manufacturing | Distributed Manufacturing |

|---|---|---|

| Definition | Layer-by-layer fabrication of parts using 3D printing technologies. | Decentralized production close to end-users using local facilities. |

| Production Scale | Typically low to medium volume, prototyping focused. | Flexible scale from small batch to mass production. |

| Lead Time | Reduced lead time via rapid prototyping and direct manufacturing. | Minimal lead time due to local manufacturing and logistics reduction. |

| Supply Chain | Centralized raw material supply, requires post-processing logistics. | Shortened and simplified supply chains with local raw materials. |

| Customization | High customization possible through digital design adjustments. | Enables mass customization by leveraging local manufacturing agility. |

| Cost Efficiency | Cost-effective for complex, low volume parts; higher unit cost at scale. | Reduces transportation and inventory costs via local production. |

| Technology Dependency | Relies on 3D printing hardware and software expertise. | Depends on networked manufacturing resources and digital platforms. |

| Environmental Impact | Less waste due to additive process; depends on energy source. | Lower carbon footprint from minimized transportation. |

Overview of Additive Manufacturing

Additive manufacturing (AM), commonly known as 3D printing, builds products layer by layer directly from digital models, enabling complex geometries and reduced material waste. This technology supports rapid prototyping, customized production, and shorter lead times compared to traditional subtractive methods. AM's integration with digital design tools enhances precision and flexibility across industries such as aerospace, healthcare, and automotive manufacturing.

Fundamentals of Distributed Manufacturing

Distributed manufacturing decentralizes production by utilizing localized facilities and digital design files to produce goods closer to end-users, reducing lead times and transportation costs. It contrasts with additive manufacturing, which is a specific technique of layer-by-layer material deposition often employed within distributed networks but not exclusive to them. Key fundamentals of distributed manufacturing include digital supply chains, modular production units, and agile responsiveness to market demand, enabling scalable and efficient manufacturing across multiple sites.

Key Differences Between Additive and Distributed Manufacturing

Additive Manufacturing builds objects layer by layer using digital 3D models, enabling complex geometries and customization, while Distributed Manufacturing decentralizes production by locating manufacturing processes closer to end-users to reduce logistics and lead times. Key differences include Additive Manufacturing's emphasis on material efficiency and design flexibility, contrasted with Distributed Manufacturing's focus on supply chain resilience and minimizing transportation costs. Both approaches leverage digital technologies but serve distinct strategic roles in modern manufacturing ecosystems.

Advantages of Additive Manufacturing

Additive manufacturing offers unparalleled design flexibility, enabling the production of complex geometries that traditional methods cannot achieve, which significantly reduces material waste and accelerates prototyping. This technology supports on-demand production, minimizing inventory costs and allowing for rapid customization tailored to specific customer needs. Furthermore, additive manufacturing streamlines supply chains by enabling localized production, cutting down lead times and reducing transportation emissions.

Benefits of Distributed Manufacturing

Distributed manufacturing enhances production efficiency by decentralizing processes closer to the end-user, reducing transportation costs and lead times. It offers greater customization and rapid response to market demands through localized production capabilities. This approach also improves supply chain resilience by minimizing dependency on centralized factories and mitigating risks from disruptions.

Challenges in Additive Manufacturing Implementation

Additive manufacturing faces challenges including high initial investment costs, limited material options, and slower production speeds compared to traditional methods. Quality control and reproducibility remain significant hurdles, impacting scalability in industrial applications. Integration with existing manufacturing systems and workforce skill gaps further complicate widespread adoption.

Distributed Manufacturing: Barriers and Solutions

Distributed manufacturing faces barriers such as supply chain complexity, quality control variations, and high initial setup costs. Overcoming these challenges involves implementing advanced digital platforms for real-time monitoring, standardizing production processes through Industry 4.0 technologies, and leveraging local logistics networks to reduce lead times. Collaboration between stakeholders and investment in workforce training enhance scalability and operational efficiency in distributed manufacturing systems.

Impact on Supply Chain and Logistics

Additive manufacturing reduces supply chain complexity by enabling on-demand production and minimizing inventory requirements, leading to shorter lead times and decreased transportation costs. Distributed manufacturing decentralizes production facilities closer to end-users, enhancing responsiveness and reducing risks associated with centralized supply chains. Both methods improve supply chain resilience by enabling localized customization and flexibility, but additive manufacturing excels in rapid prototyping while distributed manufacturing supports scalability and regional market adaptation.

Future Trends in Manufacturing Technologies

Additive manufacturing is evolving with advances in multi-material printing and faster, more precise processes, enabling complex, customized production at lower costs. Distributed manufacturing leverages IoT and cloud-connected factories to decentralize production, reduce lead times, and enhance supply chain resilience by localizing fabrication. Future trends emphasize integrating AI-driven design optimization with hybrid manufacturing systems to achieve scalable, flexible, and sustainable production models.

Choosing the Right Approach for Your Industry

Choosing the right manufacturing approach depends on factors such as production volume, customization needs, and supply chain logistics. Additive manufacturing excels in rapid prototyping and complex, low-volume parts with reduced waste, while distributed manufacturing offers scalability and resilience by decentralizing production closer to end-users. Evaluating cost efficiency, lead time, and industry-specific requirements ensures optimal alignment with business goals and market demands.

Related Important Terms

Digital Thread

Additive Manufacturing leverages the digital thread to enable precise, layer-by-layer production of complex parts directly from 3D CAD models, enhancing customization and reducing material waste. Distributed Manufacturing uses the digital thread to synchronize production across multiple decentralized locations, improving supply chain agility and reducing lead times through real-time data integration and process standardization.

Microfactory

Additive manufacturing enables precise, layer-by-layer production of complex parts, while distributed manufacturing leverages networks of microfactories to decentralize production closer to end-users, reducing lead times and transportation costs. Microfactories integrate advanced additive manufacturing technologies with smart automation, facilitating flexible, on-demand fabrication at a local scale, enhancing supply chain resilience and customization capabilities.

Distributed Additive Fabrication

Distributed additive fabrication integrates additive manufacturing technologies across multiple decentralized locations, enabling rapid production closer to end-users, reducing lead times, and minimizing logistics costs. This approach enhances supply chain resilience and customization capabilities compared to traditional centralized additive manufacturing setups.

Cloud Manufacturing

Additive manufacturing enables on-demand production through layer-by-layer fabrication, while distributed manufacturing leverages geographically dispersed facilities to reduce logistics and lead times. Cloud manufacturing integrates these approaches by providing scalable, real-time resource allocation and collaboration via cloud platforms, optimizing efficiency and responsiveness in global production networks.

Localized Production Nodes

Localized production nodes in additive manufacturing enable on-demand fabrication of complex, customized components directly at or near the point of use, reducing supply chain dependencies and lead times. Distributed manufacturing leverages a network of these nodes to decentralize production, enhance flexibility, and optimize inventory management across geographically dispersed locations.

Print Farms

Print farms in additive manufacturing enable rapid, scalable production of complex parts by utilizing multiple 3D printers simultaneously, reducing lead times and enhancing customization capabilities. Distributed manufacturing, in contrast, decentralizes production by positioning print farms closer to end-users, minimizing logistics costs and enabling on-demand, localized manufacturing workflows.

Mass Customization

Additive manufacturing enables mass customization by allowing complex, bespoke parts to be produced layer-by-layer with minimal tooling, reducing lead times and inventory costs. Distributed manufacturing complements this by decentralizing production closer to end-users, enhancing responsiveness and allowing localized customization that meets specific market demands efficiently.

Remote Slicing

Remote slicing in additive manufacturing enables the digital preparation of 3D model data on cloud-based platforms, allowing production files to be processed and optimized away from local machines. This capability supports distributed manufacturing networks by facilitating seamless collaboration, rapid iteration, and reduced lead times across geographically dispersed facilities.

Distributed Ledger in Supply Chain

Distributed manufacturing leverages distributed ledger technology to enhance supply chain transparency, traceability, and security by recording every transaction immutably across multiple nodes. This integration minimizes counterfeiting, optimizes inventory management, and ensures real-time synchronization between suppliers, manufacturers, and distributors.

Decentralized Quality Assurance

Additive manufacturing enables decentralized quality assurance by allowing real-time, on-site production inspections and adjustments, reducing defects and enhancing product consistency across multiple locations. Distributed manufacturing leverages local fabrication sites to implement quality control protocols tailored to regional requirements, improving responsiveness and minimizing delays caused by centralized oversight.

Additive Manufacturing vs Distributed Manufacturing Infographic

industrydif.com

industrydif.com