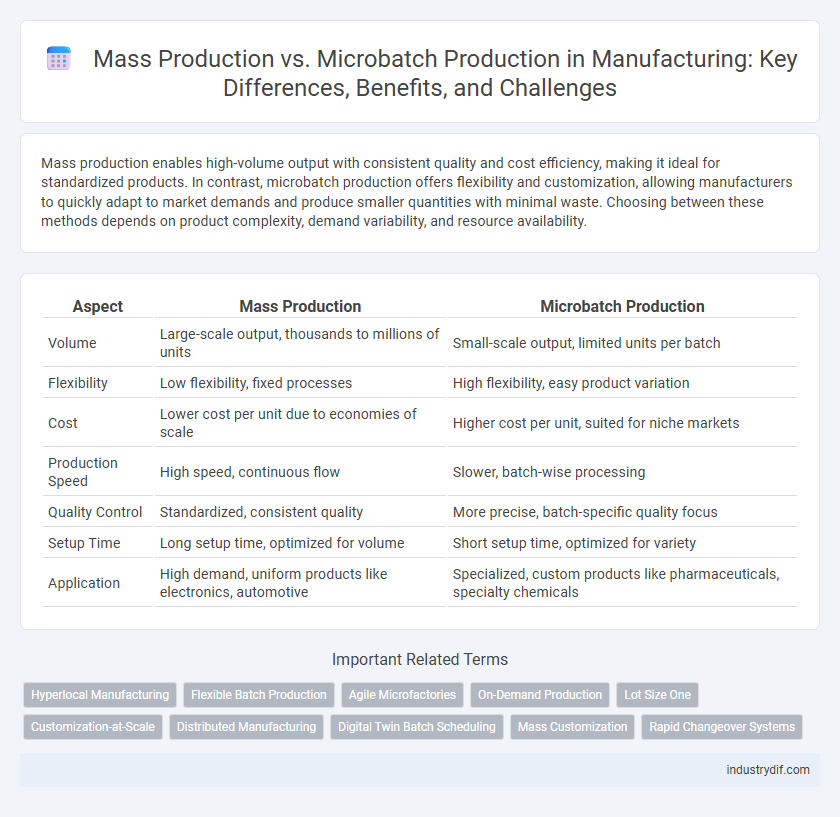

Mass production enables high-volume output with consistent quality and cost efficiency, making it ideal for standardized products. In contrast, microbatch production offers flexibility and customization, allowing manufacturers to quickly adapt to market demands and produce smaller quantities with minimal waste. Choosing between these methods depends on product complexity, demand variability, and resource availability.

Table of Comparison

| Aspect | Mass Production | Microbatch Production |

|---|---|---|

| Volume | Large-scale output, thousands to millions of units | Small-scale output, limited units per batch |

| Flexibility | Low flexibility, fixed processes | High flexibility, easy product variation |

| Cost | Lower cost per unit due to economies of scale | Higher cost per unit, suited for niche markets |

| Production Speed | High speed, continuous flow | Slower, batch-wise processing |

| Quality Control | Standardized, consistent quality | More precise, batch-specific quality focus |

| Setup Time | Long setup time, optimized for volume | Short setup time, optimized for variety |

| Application | High demand, uniform products like electronics, automotive | Specialized, custom products like pharmaceuticals, specialty chemicals |

Defining Mass Production in Modern Manufacturing

Mass production in modern manufacturing refers to the large-scale production of standardized products using assembly line techniques and automated machinery to achieve high efficiency and uniform quality. This method significantly reduces per-unit costs through economies of scale while ensuring consistent output across thousands or millions of units. Key industries utilizing mass production include automotive, electronics, and consumer goods, where demand for uniformity and volume drives manufacturing strategy.

Understanding Microbatch Production Techniques

Microbatch production techniques involve creating small, precise batches of products, enabling manufacturers to maintain high customization levels and improve quality control compared to traditional mass production. This method reduces material waste, accelerates response time to market changes, and supports the production of niche products or prototypes. Microbatch production leverages advanced automation and flexible equipment to optimize efficiency while preserving product variability and compliance with strict industry standards.

Key Differences Between Mass and Microbatch Production

Mass production emphasizes high-volume output with standardized products, maximizing efficiency through automation and continuous workflows. Microbatch production focuses on small, flexible batches, enabling customization and rapid adjustments for product variability and niche markets. Key differences lie in scale, flexibility, production speed, and capital investment requirements.

Scalability: Large-scale Versus Small-batch Manufacturing

Mass production excels in scalability by enabling large-scale manufacturing with consistent output and reduced per-unit costs through automation and streamlined processes. In contrast, microbatch production prioritizes flexibility and customization, allowing manufacturers to efficiently produce small batches tailored to specific requirements or niche markets. Scalability in mass production suits industries demanding high volume and uniformity, while microbatch production is optimal for specialized products with variable demand and rapid iteration needs.

Cost Efficiency: Mass Production vs Microbatch Costs

Mass production significantly lowers unit costs by utilizing economies of scale, making it ideal for producing large volumes of standardized products with consistent quality. In contrast, microbatch production incurs higher per-unit costs due to smaller batch sizes and more frequent changeovers, but provides greater flexibility for customization and reduced inventory risks. Companies must balance cost efficiency with product variety and market demands when choosing between mass production and microbatch production methods.

Product Customization Levels in Manufacturing

Mass production offers low product customization levels by emphasizing standardized, high-volume output to minimize costs and maximize efficiency. Microbatch production enables higher product customization, allowing manufacturers to tailor products to specific customer requirements through smaller, flexible production runs. This approach enhances adaptability and meets niche market demands, despite higher per-unit costs compared to mass production.

Quality Control Approaches in Mass and Microbatch Production

Mass production quality control emphasizes standardized testing protocols and statistical process control to maintain consistent product quality across large volumes. Microbatch production employs more flexible, frequent inspections and adaptive quality assessments to address variability in smaller quantities and customized batches. Both approaches integrate real-time monitoring technologies, but microbatch production often relies on nuanced feedback loops to ensure precision and compliance with bespoke specifications.

Supply Chain Considerations for Both Production Models

Mass production streamlines supply chain operations through standardized processes and bulk procurement, reducing per-unit costs and enhancing inventory predictability. Microbatch production demands agile supply chain management with flexible sourcing, minimizing inventory levels and accelerating responsiveness to market fluctuations. Efficient coordination between suppliers and manufacturers is crucial in both models to balance cost efficiency with production scalability and delivery timelines.

Environmental Impact: Sustainability in Production Methods

Mass production often leads to greater resource consumption and higher waste generation, intensifying environmental impact due to its scale and continuous output. Microbatch production enables more precise resource management, reducing material waste and energy usage, which supports sustainability goals by minimizing ecological footprints. Implementing microbatch methods can significantly lower emissions and improve overall environmental performance compared to traditional mass production techniques.

Industry Trends: Future of Mass and Microbatch Manufacturing

Mass production continues to dominate with advances in automation and robotics driving cost-efficiency and scalability in industries like automotive and electronics. Microbatch production gains traction in pharmaceuticals and specialty chemicals, leveraging flexible manufacturing systems and real-time analytics to meet demand for customization and rapid product iteration. Emerging trends highlight hybrid manufacturing models integrating mass and microbatch techniques to optimize supply chain resilience and product innovation.

Related Important Terms

Hyperlocal Manufacturing

Mass production enables large-scale output with standardized products, optimizing economies of scale but often sacrificing customization and local responsiveness. Hyperlocal manufacturing through microbatch production enhances flexibility, reduces transportation costs, and supports rapid adaptation to regional market demands by producing smaller quantities near consumer locations.

Flexible Batch Production

Flexible batch production optimizes manufacturing by combining the efficiency of mass production with the customization of microbatch production, enabling rapid adaptation to product variations and fluctuating demand. This approach reduces downtime and inventory costs while enhancing responsiveness and product quality across diverse manufacturing sectors.

Agile Microfactories

Agile microfactories enable flexible and efficient microbatch production, reducing lead times and minimizing inventory costs compared to traditional mass production methods. This approach enhances customization capabilities and rapid response to market demand, driving competitive advantage in modern manufacturing.

On-Demand Production

Mass production enables high-volume manufacturing with consistent output, reducing per-unit costs but often resulting in excess inventory and less flexibility. In contrast, microbatch production supports on-demand manufacturing with smaller lots, minimizing waste and allowing rapid customization to meet specific market demands efficiently.

Lot Size One

Mass production emphasizes large-scale, continuous manufacturing processes that maximize output efficiency, while microbatch production focuses on small, flexible lot sizes that enable customization and rapid response to market demands. Lot Size One exemplifies microbatch production by allowing manufacturers to produce individualized products without sacrificing cost-effectiveness or quality control.

Customization-at-Scale

Mass production enables efficient output of standardized products with limited customization, while microbatch production offers greater flexibility to tailor small batches to specific customer needs. Leveraging microbatch techniques enhances customization-at-scale by balancing production efficiency with adaptability for niche markets and personalized products.

Distributed Manufacturing

Distributed manufacturing enhances mass production scalability by decentralizing large-scale output across multiple locations, increasing flexibility and reducing lead times. Microbatch production benefits from distributed manufacturing through localized small-volume runs, enabling rapid customization and minimizing inventory costs.

Digital Twin Batch Scheduling

Digital Twin Batch Scheduling enhances mass production efficiency by simulating entire manufacturing lines for optimized resource allocation and minimized downtime. In microbatch production, digital twins enable precise batch-level adjustments, improving flexibility and reducing waste through real-time data integration and predictive analytics.

Mass Customization

Mass customization in manufacturing integrates the high efficiency of mass production with the flexibility of microbatch production to deliver personalized products at scale. This approach leverages advanced automation, modular design, and real-time data analytics to meet diverse customer demands while maintaining cost-effectiveness and rapid turnaround times.

Rapid Changeover Systems

Rapid changeover systems in mass production streamline the transition between large-scale runs, minimizing downtime to sustain high output levels. In microbatch production, these systems enable flexible, frequent changeovers that support customized manufacturing with reduced lead times and waste.

Mass Production vs Microbatch Production Infographic

industrydif.com

industrydif.com