Six Sigma focuses on reducing process variability and defects through data-driven methodologies, enhancing product quality and operational efficiency. Digital Twin Analytics leverages real-time data and simulations to create virtual replicas of manufacturing processes, enabling proactive monitoring and predictive maintenance. Combining Six Sigma with Digital Twin Analytics provides a comprehensive approach to optimizing production by blending statistical rigor with dynamic, data-rich insights.

Table of Comparison

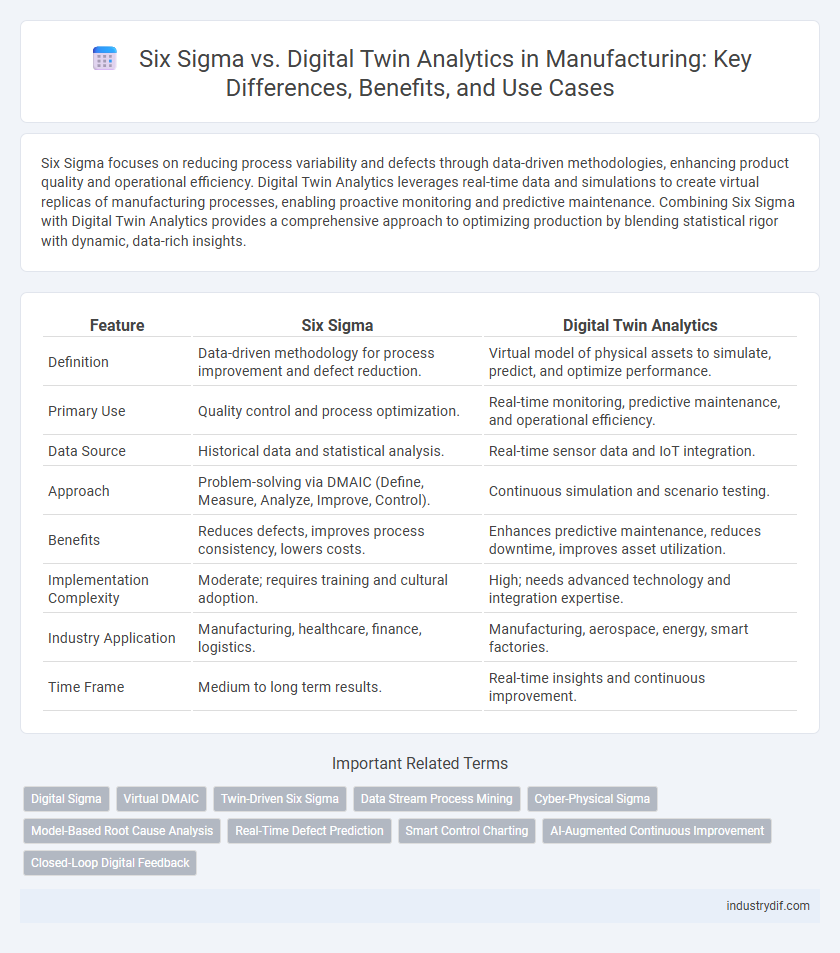

| Feature | Six Sigma | Digital Twin Analytics |

|---|---|---|

| Definition | Data-driven methodology for process improvement and defect reduction. | Virtual model of physical assets to simulate, predict, and optimize performance. |

| Primary Use | Quality control and process optimization. | Real-time monitoring, predictive maintenance, and operational efficiency. |

| Data Source | Historical data and statistical analysis. | Real-time sensor data and IoT integration. |

| Approach | Problem-solving via DMAIC (Define, Measure, Analyze, Improve, Control). | Continuous simulation and scenario testing. |

| Benefits | Reduces defects, improves process consistency, lowers costs. | Enhances predictive maintenance, reduces downtime, improves asset utilization. |

| Implementation Complexity | Moderate; requires training and cultural adoption. | High; needs advanced technology and integration expertise. |

| Industry Application | Manufacturing, healthcare, finance, logistics. | Manufacturing, aerospace, energy, smart factories. |

| Time Frame | Medium to long term results. | Real-time insights and continuous improvement. |

Introduction to Six Sigma and Digital Twin Analytics

Six Sigma is a data-driven methodology aimed at reducing defects and variability in manufacturing processes through rigorous statistical analysis and process improvement techniques. Digital Twin Analytics involves creating virtual replicas of physical manufacturing systems to simulate, predict, and optimize performance in real-time using advanced sensors and IoT data. Both approaches enhance operational efficiency, with Six Sigma focusing on quality control and process optimization, while Digital Twin Analytics enables dynamic system monitoring and predictive maintenance.

Defining Key Concepts: Six Sigma vs Digital Twin Analytics

Six Sigma is a data-driven methodology focused on reducing defects and improving process quality by identifying and eliminating variability through DMAIC (Define, Measure, Analyze, Improve, Control) phases. Digital Twin Analytics utilizes real-time digital replicas of physical manufacturing systems to simulate, predict, and optimize performance by integrating IoT data, AI, and advanced modeling. While Six Sigma emphasizes statistical process control and continuous improvement, Digital Twin Analytics enables dynamic, data-rich visualization and scenario testing for proactive decision-making in manufacturing operations.

Core Principles and Methodologies

Six Sigma emphasizes defect reduction and process improvement using data-driven DMAIC methodology--Define, Measure, Analyze, Improve, Control--to enhance manufacturing quality and efficiency. Digital Twin Analytics leverages real-time simulation and data integration to create virtual replicas of physical assets, enabling predictive maintenance and dynamic process optimization. Both approaches prioritize data accuracy and continuous improvement, but Six Sigma is rooted in statistical analysis, while Digital Twin Analytics focuses on real-time operational insights through advanced modeling.

Data-Driven Decision Making in Manufacturing

Six Sigma leverages statistical analysis and process control to reduce defects and enhance manufacturing quality by driving data-driven decision making through rigorous measurement and improvement cycles. Digital Twin Analytics utilizes real-time data from virtual replicas of physical assets, enabling predictive insights and dynamic optimization of manufacturing processes. Integrating these methodologies accelerates operational efficiency, minimizes downtime, and supports proactive quality management in modern smart factories.

Process Optimization: Comparative Analysis

Six Sigma employs statistical methods to reduce process variation and enhance quality control, driving continuous improvement through data-driven decision-making. Digital Twin Analytics creates virtual replicas of manufacturing processes, enabling real-time simulation and predictive analysis to identify inefficiencies and optimize operations dynamically. Combining Six Sigma's structured methodology with Digital Twin's real-time insights offers a synergistic approach to maximizing process optimization in manufacturing.

Real-Time Monitoring and Predictive Insights

Six Sigma enhances manufacturing quality by reducing process variations through statistical analysis, while Digital Twin Analytics leverages real-time monitoring of virtual replicas to simulate and predict equipment performance. Real-time data integration in Digital Twin Analytics enables faster anomaly detection and dynamic process adjustments, surpassing traditional Six Sigma's periodic sampling methods. Predictive insights from Digital Twins facilitate proactive maintenance and optimized production schedules, driving higher operational efficiency and reduced downtime.

Implementation Challenges and Solutions

Implementation challenges in Six Sigma often involve data integration complexities and resistance to cultural change within manufacturing processes, whereas Digital Twin Analytics faces obstacles related to high computational demands and real-time data accuracy. Solutions for Six Sigma include robust training programs and cross-functional teams to foster collaboration, while Digital Twin implementations benefit from advanced IoT sensors and edge computing to enhance data fidelity and processing speed. Both methodologies require strategic alignment with organizational goals to optimize operational efficiency and drive continuous improvement in manufacturing environments.

Integration with Industry 4.0 Technologies

Six Sigma enhances manufacturing quality through data-driven process improvements, while Digital Twin Analytics offers real-time simulation and predictive insights by creating virtual replicas of physical assets. Integration with Industry 4.0 technologies like IoT sensors, cloud computing, and AI accelerates Digital Twin Analytics by providing continuous data streams for dynamic modeling and optimization. Combining Six Sigma methodologies with Digital Twin Analytics and Industry 4.0 enables holistic process control, reducing defects and operational downtime with advanced predictive maintenance and automated decision-making.

Case Studies: Success Stories and Outcomes

Case studies reveal Six Sigma's effectiveness in manufacturing through projects that reduced defects by up to 50% and increased process efficiency by 30%, demonstrating its focus on quality improvement and waste reduction. Digital Twin Analytics success stories highlight predictive maintenance with uptime improvements of 20% and cost savings exceeding $1 million annually by simulating real-time factory conditions. Combining both methodologies drives innovation, where Six Sigma's structured problem-solving complements Digital Twin's advanced simulation capabilities to maximize operational performance and reduce downtime.

Future Trends in Manufacturing Analytics

Six Sigma continues to provide robust quality improvement frameworks by reducing defects and enhancing process efficiency in manufacturing. Digital Twin Analytics is rapidly advancing, enabling real-time simulation and predictive maintenance through virtual replicas of physical assets. Future trends indicate a convergence where integrated Six Sigma methodologies leverage data insights from Digital Twin platforms to drive smarter, data-driven decision-making and operational excellence.

Related Important Terms

Digital Sigma

Digital Sigma integrates Six Sigma methodologies with Digital Twin Analytics to enhance manufacturing process optimization by simulating real-time operational data and identifying defects more precisely. Leveraging virtual models, Digital Sigma enables predictive quality control and continuous improvement, surpassing traditional Six Sigma's reliance on historical data analysis.

Virtual DMAIC

Virtual DMAIC enhances Six Sigma by integrating Digital Twin Analytics to simulate, analyze, and optimize manufacturing processes in a virtual environment before implementation. This convergence accelerates defect reduction and process improvement by enabling real-time data-driven decision-making and predictive modeling within the Define, Measure, Analyze, Improve, and Control phases.

Twin-Driven Six Sigma

Twin-Driven Six Sigma integrates Digital Twin Analytics with Six Sigma methodologies to enhance process optimization and defect reduction in manufacturing by creating real-time, virtual replicas of production systems for data-driven decision-making. This approach accelerates problem identification, reduces variability, and improves yield through precise simulation and predictive analysis, outperforming traditional Six Sigma alone.

Data Stream Process Mining

Six Sigma leverages statistical analysis and process mapping to reduce defects and improve manufacturing quality, whereas Digital Twin Analytics integrates real-time sensor data and simulation models to optimize operations dynamically. Data Stream Process Mining enhances both approaches by continuously extracting actionable insights from live data flows, enabling proactive process improvements and predictive maintenance.

Cyber-Physical Sigma

Cyber-Physical Sigma integrates Six Sigma methodologies with Digital Twin Analytics to enhance manufacturing process optimization through real-time data monitoring and predictive modeling. This approach leverages cyber-physical systems to reduce defects, improve quality, and drive continuous improvement by simulating production scenarios and identifying process variations before they impact operations.

Model-Based Root Cause Analysis

Six Sigma utilizes statistical methods to identify process variations and defects, while Digital Twin Analytics employs real-time, model-based simulations to pinpoint root causes with higher precision. Model-Based Root Cause Analysis in Digital Twin environments enables dynamic scenario testing and predictive insights, surpassing traditional Six Sigma's reliance on historical data.

Real-Time Defect Prediction

Six Sigma employs historical data and statistical analysis to reduce defects, while Digital Twin Analytics uses real-time sensor data and machine learning models for immediate defect prediction and process optimization. Integrating Digital Twin Analytics enhances Six Sigma's capabilities by enabling proactive interventions and minimizing production downtime through dynamic simulation and continuous monitoring.

Smart Control Charting

Six Sigma enhances manufacturing quality by using statistical methods to reduce defects, while Digital Twin Analytics employs real-time data from virtual replicas to predict and optimize processes. Smart Control Charting integrates these approaches by combining Six Sigma's statistical rigor with Digital Twin's dynamic data insights, enabling proactive monitoring and adaptive process control for improved efficiency and reduced variability.

AI-Augmented Continuous Improvement

AI-augmented continuous improvement leverages Six Sigma's statistical rigor alongside Digital Twin Analytics' real-time simulation capabilities to optimize manufacturing processes. Integrating these methodologies enables predictive defect reduction and dynamic process adjustments, driving enhanced operational efficiency and quality control.

Closed-Loop Digital Feedback

Six Sigma emphasizes reducing process variation and defects through data-driven statistical analysis, while Digital Twin Analytics leverages real-time, closed-loop digital feedback by creating virtual replicas of physical manufacturing systems for continuous optimization. The integration of closed-loop digital feedback enables dynamic adjustments, enhancing predictive maintenance and operational efficiency beyond traditional Six Sigma methodologies.

Six Sigma vs Digital Twin Analytics Infographic

industrydif.com

industrydif.com