Six Sigma emphasizes reducing defects and variability through data-driven processes, while Industry 4.0 leverages advanced technologies like IoT, AI, and automation to enhance manufacturing efficiency and connectivity. Integrating Six Sigma methodologies with Industry 4.0 tools optimizes quality control and real-time decision-making, driving continuous improvement. This combination enables manufacturers to achieve higher precision, lower costs, and faster production cycles.

Table of Comparison

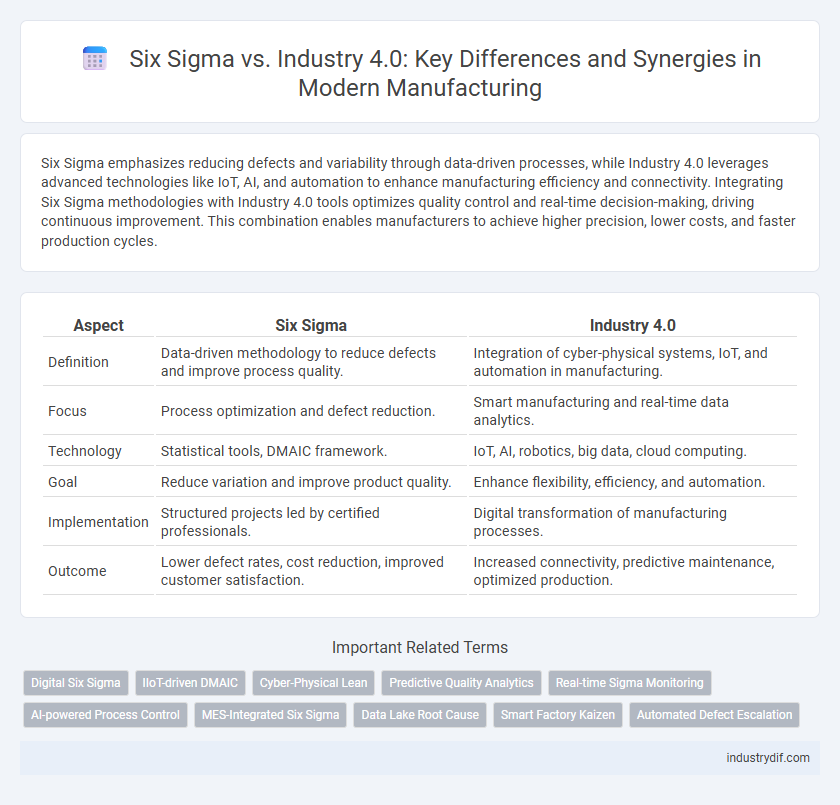

| Aspect | Six Sigma | Industry 4.0 |

|---|---|---|

| Definition | Data-driven methodology to reduce defects and improve process quality. | Integration of cyber-physical systems, IoT, and automation in manufacturing. |

| Focus | Process optimization and defect reduction. | Smart manufacturing and real-time data analytics. |

| Technology | Statistical tools, DMAIC framework. | IoT, AI, robotics, big data, cloud computing. |

| Goal | Reduce variation and improve product quality. | Enhance flexibility, efficiency, and automation. |

| Implementation | Structured projects led by certified professionals. | Digital transformation of manufacturing processes. |

| Outcome | Lower defect rates, cost reduction, improved customer satisfaction. | Increased connectivity, predictive maintenance, optimized production. |

Defining Six Sigma and Industry 4.0

Six Sigma is a data-driven methodology focused on reducing defects and improving quality through statistical analysis and process control in manufacturing. Industry 4.0 represents the integration of cyber-physical systems, IoT, and big data analytics to create smart factories that optimize production efficiency and flexibility. Both approaches aim to enhance manufacturing performance, with Six Sigma emphasizing process precision and Industry 4.0 driving digital transformation.

Historical Evolution of Manufacturing Methodologies

Six Sigma, developed in the 1980s, revolutionized manufacturing by introducing data-driven quality control and process improvement techniques that reduced defects and enhanced operational efficiency. Industry 4.0, emerging in the early 21st century, represents a paradigm shift through the integration of cyber-physical systems, IoT, and advanced automation, enabling smart manufacturing. The historical evolution from Six Sigma to Industry 4.0 reflects manufacturing's transition from statistical quality management to interconnected, real-time data-driven production systems.

Core Principles: Six Sigma vs Industry 4.0

Six Sigma centers on reducing process variation and improving quality through data-driven statistical methods and DMAIC (Define, Measure, Analyze, Improve, Control) cycles, emphasizing defect reduction and consistent output. Industry 4.0 integrates cyber-physical systems, IoT, big data analytics, and automation to create smart factories that enable real-time decision-making and adaptive manufacturing processes. While Six Sigma aims at process perfection through structured problem-solving, Industry 4.0 focuses on digital transformation and connectivity to enhance flexibility, efficiency, and predictive capabilities in manufacturing.

Process Optimization Approaches

Six Sigma focuses on minimizing process variability and defects through data-driven methodologies like DMAIC, resulting in consistent quality improvements in manufacturing. Industry 4.0 leverages cyber-physical systems, IoT, and real-time data analytics to enable adaptive, automated process optimization with enhanced transparency and efficiency. Integrating Six Sigma's structured problem-solving with Industry 4.0's smart technologies accelerates continuous improvement and operational excellence in modern manufacturing environments.

Role of Data Analytics and Automation

Six Sigma uses statistical data analysis to reduce process variation and improve product quality by identifying defects and driving continuous improvement in manufacturing operations. Industry 4.0 integrates advanced automation, IoT sensors, and real-time data analytics, enabling smart factories to optimize production efficiency and predictive maintenance. Combining Six Sigma methodologies with Industry 4.0 technologies enhances decision-making by leveraging big data analytics and automated systems for superior process control.

Implementation Challenges in Modern Manufacturing

Implementing Six Sigma in modern manufacturing often faces challenges such as resistance to cultural change, extensive training requirements, and difficulty integrating statistical methods with complex production systems. Industry 4.0 introduces hurdles including high initial investment costs, cybersecurity risks, and the need for skilled personnel proficient in IoT, AI, and big data analytics. Both approaches demand significant organizational commitment, yet Industry 4.0's rapid technology evolution requires continuous adaptation compared to Six Sigma's more structured methodology.

Impact on Quality Control and Continuous Improvement

Six Sigma enhances quality control through data-driven methodologies that reduce process variability and defects, achieving near-perfect production standards. Industry 4.0 integrates advanced technologies like IoT, AI, and real-time analytics to enable predictive quality control and automate continuous improvement cycles. The synergy of Six Sigma's statistical rigor with Industry 4.0's digital infrastructure accelerates defect detection, process optimization, and adaptive quality management.

Integrating Six Sigma with Industry 4.0 Technologies

Integrating Six Sigma with Industry 4.0 technologies enhances manufacturing efficiency by combining data-driven quality management with advanced automation and IoT. Leveraging real-time analytics, machine learning, and cyber-physical systems enables continuous process improvement and defect reduction at unprecedented levels. This synergy drives predictive maintenance, reduces variability, and accelerates decision-making in smart factories.

Case Studies: Success Stories and Lessons Learned

Case studies in manufacturing reveal Six Sigma's effectiveness in reducing defects by up to 50% through rigorous data-driven problem-solving, while Industry 4.0 integrates smart sensors and IoT to enable real-time monitoring and predictive maintenance, boosting productivity by 30%. Success stories highlight how combining Six Sigma methodologies with Industry 4.0 technologies accelerates continuous improvement and operational excellence. Lessons learned emphasize the importance of skilled teams and data quality to fully leverage the synergy between these approaches for sustainable manufacturing growth.

Future Trends in Manufacturing: Synergy or Divergence?

Future trends in manufacturing reveal a dynamic interplay between Six Sigma methodologies and Industry 4.0 technologies, emphasizing data-driven quality improvement and automation integration. Six Sigma's rigorous statistical analysis complements Industry 4.0's cyber-physical systems, enabling real-time process optimization and defect reduction. The convergence of these approaches fosters smart factories with enhanced efficiency, predictive maintenance, and adaptive manufacturing processes.

Related Important Terms

Digital Six Sigma

Digital Six Sigma integrates advanced Industry 4.0 technologies such as IoT, big data analytics, and AI to enhance traditional Six Sigma methodologies, driving higher precision in defect reduction and process optimization. This synergy enables real-time data monitoring and predictive quality control, revolutionizing manufacturing efficiency and product consistency.

IIoT-driven DMAIC

Six Sigma's DMAIC framework enhances manufacturing quality through Define, Measure, Analyze, Improve, and Control phases, now revolutionized by Industry 4.0 with IIoT integration enabling real-time data analytics, predictive maintenance, and automated process control. IIoT-driven DMAIC accelerates defect detection, optimizes resource utilization, and reduces downtime, propelling operational efficiency and continuous improvement in smart factories.

Cyber-Physical Lean

Cyber-Physical Lean integrates Six Sigma's data-driven defect reduction with Industry 4.0's advanced automation and real-time sensor data to optimize manufacturing processes. This synergy enhances quality control, reduces waste, and accelerates decision-making through interconnected cyber-physical systems.

Predictive Quality Analytics

Six Sigma leverages statistical methods to reduce defects and improve process quality, while Industry 4.0 utilizes IoT sensors and machine learning algorithms to enable real-time predictive quality analytics. Integrating Industry 4.0 technologies with Six Sigma frameworks enhances data-driven decision-making, enabling manufacturers to anticipate defects and optimize production efficiency proactively.

Real-time Sigma Monitoring

Real-time Sigma monitoring in Industry 4.0 leverages IoT sensors, AI analytics, and cloud computing to provide continuous, precise quality control compared to traditional Six Sigma methods that primarily rely on periodic data sampling and retrospective analysis. This integration enables manufacturers to detect process deviations instantly, reduce defects, and improve overall operational efficiency in dynamic production environments.

AI-powered Process Control

AI-powered process control in Industry 4.0 leverages advanced machine learning algorithms and real-time data analytics to optimize manufacturing workflows far beyond traditional Six Sigma statistical methods. While Six Sigma focuses on reducing defects through measurable quality improvements, Industry 4.0 integrates AI to enable predictive maintenance, adaptive control, and autonomous decision-making, driving unprecedented efficiency and process innovation.

MES-Integrated Six Sigma

MES-integrated Six Sigma combines real-time manufacturing execution system data with Six Sigma methodologies to enhance process control, reduce defects, and optimize quality in Industry 4.0 environments. This integration enables precise data-driven decision-making, improving production efficiency and driving continuous improvement through digital transformation.

Data Lake Root Cause

Six Sigma utilizes structured statistical methods to identify root causes of manufacturing defects, while Industry 4.0 leverages data lakes to aggregate vast amounts of real-time sensor and IoT data for deeper root cause analysis. Integrating Six Sigma with Industry 4.0's data lake architecture enhances predictive maintenance and process optimization by combining historical quality metrics with live operational data streams.

Smart Factory Kaizen

Smart Factory Kaizen integrates Six Sigma's rigorous quality control methodologies with Industry 4.0's advanced automation and data analytics to enhance continuous improvement processes in manufacturing. This synergy enables real-time defect detection, predictive maintenance, and optimized production workflows, driving higher efficiency and reduced operational costs.

Automated Defect Escalation

Six Sigma's automated defect escalation enhances manufacturing quality by systematically identifying and addressing defects to reduce variability and improve process efficiency. Industry 4.0 integrates advanced sensors, IoT connectivity, and AI-driven analytics to enable real-time automated defect detection and escalation, accelerating response times and minimizing production downtime.

Six Sigma vs Industry 4.0 Infographic

industrydif.com

industrydif.com