Flexible Manufacturing Systems (FMS) offer adaptability by allowing quick changes in production setups to handle multiple product types efficiently, enhancing responsiveness to market demands. Lights Out Manufacturing operates with minimal or no human presence, relying heavily on automation and robotics for continuous, around-the-clock production that increases throughput and reduces labor costs. Combining FMS's versatility with Lights Out Manufacturing's efficiency can optimize production by balancing flexibility and high-volume output in modern manufacturing environments.

Table of Comparison

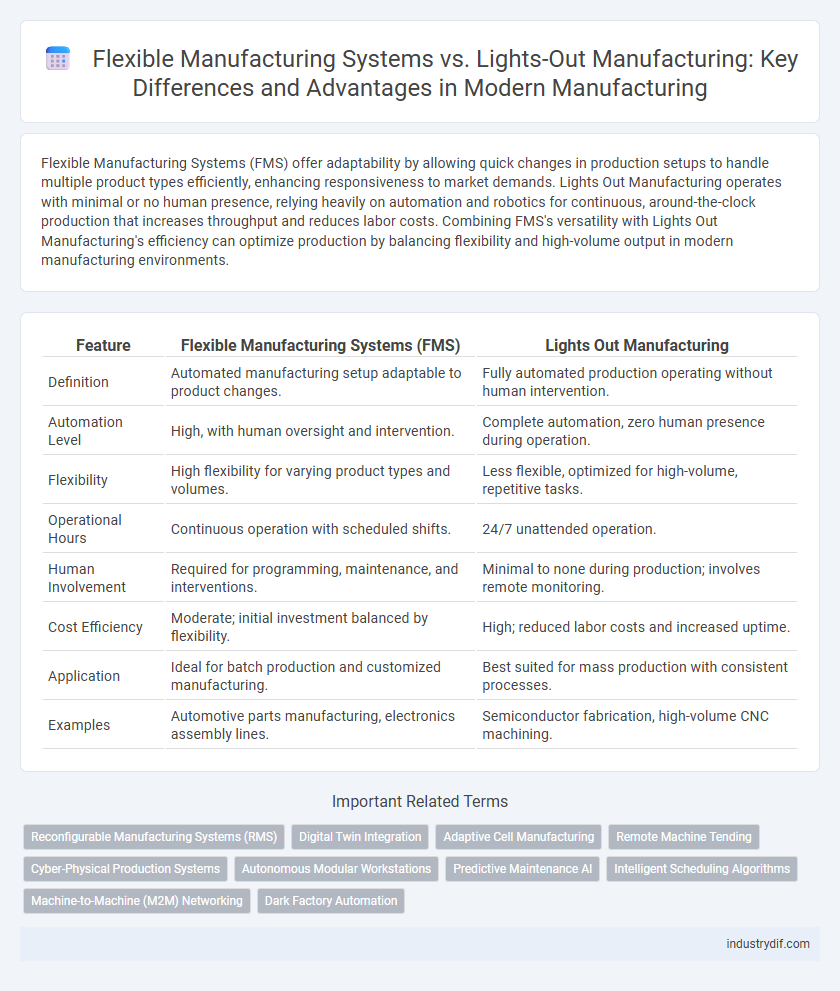

| Feature | Flexible Manufacturing Systems (FMS) | Lights Out Manufacturing |

|---|---|---|

| Definition | Automated manufacturing setup adaptable to product changes. | Fully automated production operating without human intervention. |

| Automation Level | High, with human oversight and intervention. | Complete automation, zero human presence during operation. |

| Flexibility | High flexibility for varying product types and volumes. | Less flexible, optimized for high-volume, repetitive tasks. |

| Operational Hours | Continuous operation with scheduled shifts. | 24/7 unattended operation. |

| Human Involvement | Required for programming, maintenance, and interventions. | Minimal to none during production; involves remote monitoring. |

| Cost Efficiency | Moderate; initial investment balanced by flexibility. | High; reduced labor costs and increased uptime. |

| Application | Ideal for batch production and customized manufacturing. | Best suited for mass production with consistent processes. |

| Examples | Automotive parts manufacturing, electronics assembly lines. | Semiconductor fabrication, high-volume CNC machining. |

Introduction to Flexible Manufacturing Systems

Flexible Manufacturing Systems (FMS) integrate computer-controlled machines, automated material handling, and centralized control to enhance production flexibility and efficiency. These systems enable manufacturers to rapidly switch between different products while maintaining high-volume output and minimizing downtime. FMS supports customization and reduces lead times, making it a critical component in agile manufacturing environments.

Defining Lights Out Manufacturing

Lights Out Manufacturing refers to fully automated production processes that operate without human intervention, leveraging robotics, advanced sensors, and AI-driven control systems. Unlike Flexible Manufacturing Systems, which adapt to varying product types with some human oversight, Lights Out Manufacturing aims for continuous, unattended operation to maximize efficiency and reduce labor costs. This approach enhances precision and throughput while minimizing downtime and human error in smart factories.

Key Components of Flexible Manufacturing Systems

Flexible Manufacturing Systems (FMS) are characterized by key components including automated CNC machines, material handling systems, and centralized control software that enables real-time production adjustments. These systems facilitate flexible production scheduling and part variation, optimizing manufacturing efficiency and reducing downtime. In contrast, Lights Out Manufacturing focuses on fully automated, unattended operations primarily driven by robotics and advanced sensor technology.

Core Technologies in Lights Out Manufacturing

Lights Out Manufacturing relies heavily on advanced automation technologies such as robotics, artificial intelligence (AI), and the Internet of Things (IoT) to enable fully autonomous production processes without human intervention. Core technologies include machine learning algorithms for predictive maintenance, automated guided vehicles (AGVs) for material handling, and integrated sensor networks for real-time monitoring and control. These innovations contrast with Flexible Manufacturing Systems, which incorporate human oversight and adaptability but lack the complete autonomy intrinsic to Lights Out Manufacturing.

Automation Levels: FMS vs Lights Out Manufacturing

Flexible Manufacturing Systems (FMS) incorporate automated machines and robotics with human oversight to adjust production quickly based on demand, offering moderate to high automation levels. Lights Out Manufacturing operates at full automation with minimal to zero human intervention, enabling continuous, unattended production. The automation level in Lights Out Manufacturing surpasses FMS by eliminating manual processes entirely, driving efficiency in high-volume, repetitive manufacturing environments.

Flexibility and Adaptability in Production

Flexible Manufacturing Systems (FMS) enable rapid adaptation to changing product designs and batch sizes by integrating computer-controlled machinery and automated material handling, enhancing customization and reducing downtime. Lights Out Manufacturing operates with minimal human intervention, focusing on continuous, unattended production to maximize efficiency but with less flexibility to accommodate frequent changes. FMS offers superior adaptability for varied production requirements, while Lights Out Manufacturing excels in high-volume, consistent output environments.

Cost Efficiency: Comparative Analysis

Flexible Manufacturing Systems (FMS) offer cost efficiency through adaptability, reducing downtime and minimizing labor costs by integrating automated machinery that can quickly switch between product types. Lights Out Manufacturing achieves higher cost savings by operating fully automated facilities with minimal human intervention, drastically cutting labor expenses and energy consumption during off-hours. While FMS balances initial investment with versatile production capabilities, Lights Out Manufacturing maximizes long-term operational savings through continuous, unattended production cycles.

Challenges and Limitations of Each Approach

Flexible Manufacturing Systems face challenges in high initial investment costs and complex integration of diverse machinery, limiting scalability in certain industries. Lights Out Manufacturing struggles with limited adaptability to unexpected disruptions due to full automation reliance and requires robust predictive maintenance to avoid costly downtime. Both approaches demand advanced software and skilled personnel, but varying operational flexibility and maintenance complexities define their limitations.

Integration with Industry 4.0 Initiatives

Flexible Manufacturing Systems (FMS) seamlessly integrate with Industry 4.0 initiatives through the use of IoT sensors, real-time data analytics, and adaptive robotics to enable dynamic production adjustments and enhance operational efficiency. Lights Out Manufacturing relies heavily on autonomous systems and AI-driven monitoring, emphasizing fully automated processes with minimal human intervention, perfectly aligning with smart factory objectives of Industry 4.0. Both systems leverage cloud computing and advanced cybersecurity protocols to enhance connectivity and data security within smart manufacturing ecosystems.

Future Trends in Smart Manufacturing Systems

Flexible Manufacturing Systems (FMS) and Lights Out Manufacturing represent key advancements in smart manufacturing systems, emphasizing adaptability and automation. Future trends indicate increased integration of AI-driven decision-making, IoT connectivity, and real-time data analytics to enhance system responsiveness and operational efficiency. The convergence of these technologies will enable fully autonomous production environments with minimal human intervention, optimizing resource utilization and reducing downtime.

Related Important Terms

Reconfigurable Manufacturing Systems (RMS)

Reconfigurable Manufacturing Systems (RMS) enhance flexibility by enabling rapid adaptation of production resources to changing product demands, differentiating from traditional Flexible Manufacturing Systems (FMS) that prioritize versatility but with limited quick reconfiguration. Unlike Lights Out Manufacturing, which emphasizes fully automated, unmanned operations for efficiency, RMS focus on modularity and scalability, allowing manufacturers to efficiently retool and customize production lines to meet evolving market requirements.

Digital Twin Integration

Flexible Manufacturing Systems (FMS) leverage Digital Twin Integration to simulate and optimize production workflows in real-time, enabling rapid adjustments to changing demands and reducing downtime. Lights Out Manufacturing intensifies this integration by utilizing Digital Twins for autonomous monitoring and control, achieving fully automated, unmanned factory operation with enhanced precision and efficiency.

Adaptive Cell Manufacturing

Adaptive Cell Manufacturing integrates flexible manufacturing systems (FMS) with automated processes to optimize production efficiency, allowing real-time adjustments to product variations and demand fluctuations. This approach contrasts with lights out manufacturing, which emphasizes fully autonomous, unattended operation, whereas adaptive cells maintain human oversight for dynamic decision-making and customization.

Remote Machine Tending

Flexible Manufacturing Systems (FMS) enable remote machine tending through automated material handling and adaptive robotics, allowing seamless adjustments to production schedules and part variations. Lights Out Manufacturing relies heavily on remote machine tending with fully autonomous systems and real-time monitoring, minimizing human intervention and maximizing operational uptime during unmanned shifts.

Cyber-Physical Production Systems

Cyber-Physical Production Systems (CPPS) integrate sensors, actuators, and data analytics within Flexible Manufacturing Systems (FMS) to enable real-time monitoring and adaptive control, enhancing production agility and efficiency. In Lights Out Manufacturing, CPPS facilitate fully automated, unattended operations through advanced connectivity and autonomous decision-making, reducing human intervention and operational costs.

Autonomous Modular Workstations

Autonomous modular workstations in Flexible Manufacturing Systems (FMS) enable adaptable production workflows by integrating reconfigurable machinery and real-time data analytics, enhancing operational flexibility and minimizing downtime. Lights Out Manufacturing relies on these autonomous modules to maintain continuous, unmanned production cycles, optimizing efficiency through automated decision-making and self-monitoring capabilities.

Predictive Maintenance AI

Flexible Manufacturing Systems (FMS) leverage predictive maintenance AI to monitor equipment health in real-time, minimizing downtime and optimizing production schedules through adaptive responses to machine conditions. Lights Out Manufacturing employs advanced predictive maintenance algorithms to enable fully autonomous operations by forecasting failures before they occur, ensuring uninterrupted processes in unmanned facilities.

Intelligent Scheduling Algorithms

Flexible Manufacturing Systems (FMS) leverage intelligent scheduling algorithms to dynamically allocate resources and optimize production workflows, enhancing adaptability to varying product demands and reducing downtime. Lights Out Manufacturing employs advanced AI-driven scheduling techniques to enable fully autonomous operations with minimal human intervention, maximizing efficiency and throughput during unattended production periods.

Machine-to-Machine (M2M) Networking

Flexible Manufacturing Systems (FMS) leverage Machine-to-Machine (M2M) networking to enable real-time communication between multiple machines, optimizing production adaptability and minimizing downtime through networked automation. Lights Out Manufacturing relies heavily on advanced M2M networking for fully autonomous operations, allowing machines to execute tasks, self-monitor, and adjust processes without human intervention, maximizing efficiency in unmanned environments.

Dark Factory Automation

Dark factory automation epitomizes lights-out manufacturing by enabling fully autonomous production processes without human intervention, leveraging advanced robotics, AI, and IoT connectivity to optimize efficiency and minimize downtime. Flexible manufacturing systems support this by providing adaptable machinery and digitally controlled workflows that seamlessly integrate with dark factory technologies for dynamic, high-volume manufacturing operations.

Flexible Manufacturing Systems vs Lights Out Manufacturing Infographic

industrydif.com

industrydif.com