Supply Chain Management (SCM) involves planning, controlling, and executing supply chain operations to optimize efficiency and reduce costs in manufacturing. Supply Chain Digital Twin enhances SCM by creating a virtual replica of the entire supply chain, enabling real-time monitoring, simulation, and predictive analysis for better decision-making. Implementing a digital twin improves responsiveness to disruptions, minimizes risks, and drives continuous improvement in manufacturing supply chains.

Table of Comparison

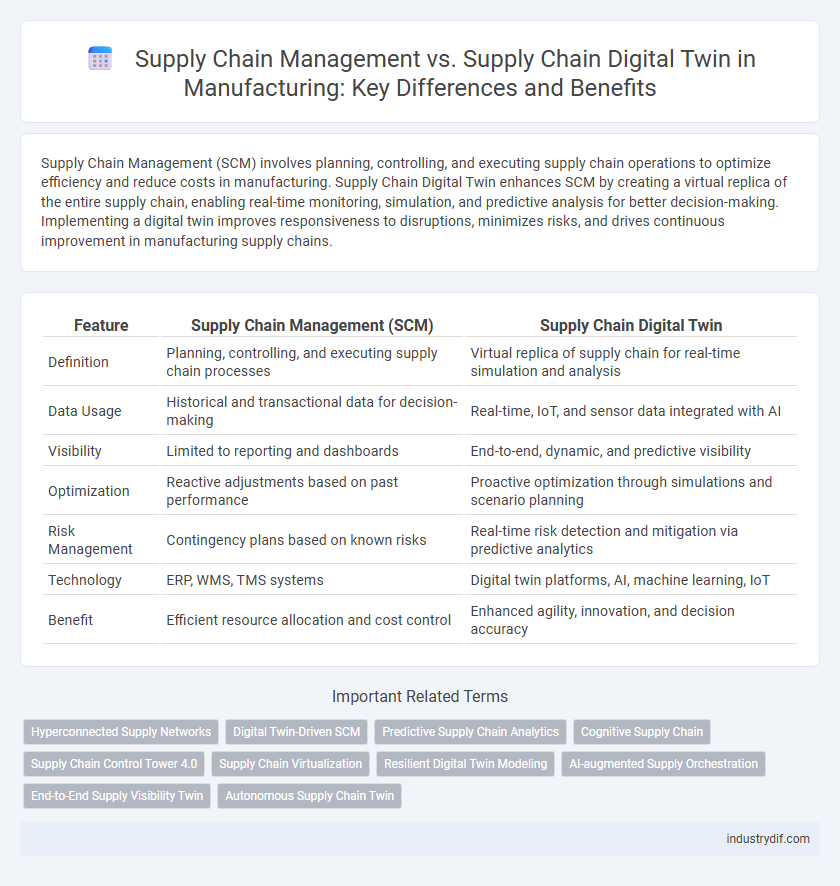

| Feature | Supply Chain Management (SCM) | Supply Chain Digital Twin |

|---|---|---|

| Definition | Planning, controlling, and executing supply chain processes | Virtual replica of supply chain for real-time simulation and analysis |

| Data Usage | Historical and transactional data for decision-making | Real-time, IoT, and sensor data integrated with AI |

| Visibility | Limited to reporting and dashboards | End-to-end, dynamic, and predictive visibility |

| Optimization | Reactive adjustments based on past performance | Proactive optimization through simulations and scenario planning |

| Risk Management | Contingency plans based on known risks | Real-time risk detection and mitigation via predictive analytics |

| Technology | ERP, WMS, TMS systems | Digital twin platforms, AI, machine learning, IoT |

| Benefit | Efficient resource allocation and cost control | Enhanced agility, innovation, and decision accuracy |

Understanding Traditional Supply Chain Management

Traditional Supply Chain Management involves coordinating the flow of goods, information, and finances from suppliers to manufacturers to distributors, focusing on inventory control, demand forecasting, and logistics optimization. It relies heavily on historical data and manual processes, limiting real-time visibility and responsiveness to disruptions. In contrast, Supply Chain Digital Twin uses advanced simulations and real-time data integration to create a virtual replica of the supply chain, enabling predictive analytics and proactive decision-making.

What Is a Supply Chain Digital Twin?

A Supply Chain Digital Twin is a dynamic virtual model that replicates the physical supply chain's processes, operations, and data in real-time, enabling enhanced visibility and predictive analytics. It integrates IoT sensors, AI algorithms, and big data to simulate and optimize supply chain performance, risk management, and decision-making. Unlike traditional Supply Chain Management, which focuses on planning and execution, the digital twin offers continuous monitoring and scenario testing for proactive adjustments and efficiency improvements.

Key Differences Between SCM and Digital Twin Approaches

Supply Chain Management (SCM) focuses on planning, sourcing, production, and logistics coordination to optimize the flow of goods and information across the supply chain. In contrast, Supply Chain Digital Twin creates a dynamic, virtual replica of the supply chain that enables real-time simulation, predictive analytics, and scenario testing to enhance decision-making. Key differences include SCM's emphasis on operational execution and coordination, while Digital Twins prioritize continuous monitoring, data-driven insights, and proactive risk management through advanced modeling technologies.

Core Benefits of Supply Chain Management

Supply Chain Management (SCM) optimizes procurement, production, and logistics to enhance operational efficiency and reduce costs across the manufacturing process. Core benefits include improved inventory control, increased supplier collaboration, and enhanced demand forecasting accuracy, leading to smoother production flows. Effective SCM ensures timely delivery of raw materials and finished goods, minimizing downtime and meeting customer expectations.

Advantages of Implementing a Supply Chain Digital Twin

Implementing a Supply Chain Digital Twin enhances real-time visibility and predictive analytics, enabling manufacturers to simulate and optimize operations with higher accuracy compared to traditional Supply Chain Management. This advanced technology allows for proactive risk mitigation, reducing downtime and improving demand forecasting through data-driven insights. Leveraging digital twins significantly boosts supply chain agility, cost efficiency, and resilience against disruptions.

Real-Time Data Integration in Modern Supply Chains

Supply Chain Management relies on traditional data collection methods that often lead to delayed decision-making and inefficiencies. Supply Chain Digital Twin technology integrates real-time data from IoT sensors, GPS tracking, and ERP systems to create dynamic, accurate virtual replicas of physical supply chains, enabling proactive adjustments. This real-time data integration enhances demand forecasting, reduces lead times, and optimizes inventory management across modern supply networks.

Risk Management: Traditional vs. Digital Twin Methods

Traditional supply chain risk management relies heavily on historical data and manual assessments, often leading to delayed responses and limited predictive capabilities. Supply chain digital twin technology leverages real-time data integration, advanced simulations, and AI-driven analytics to identify potential disruptions proactively and optimize contingency plans. This digital approach enhances resilience by enabling continuous risk monitoring, scenario analysis, and faster adaptation to unforeseen events.

Operational Efficiency and Predictive Analytics

Supply Chain Management (SCM) focuses on optimizing the flow of goods and information across production, inventory, and distribution to improve operational efficiency. Supply Chain Digital Twin leverages real-time data, simulations, and predictive analytics to model, monitor, and forecast supply chain scenarios, enabling proactive decision-making and risk mitigation. Integrating digital twins enhances operational efficiency by identifying bottlenecks and predicting disruptions before they impact manufacturing processes.

Challenges in Adopting Digital Twin Technology

Supply chain digital twin technology faces adoption challenges such as high implementation costs, data integration complexities, and resistance to change within traditional supply chain management frameworks. Ensuring real-time data accuracy and system interoperability requires advanced IT infrastructure and skilled personnel, often lacking in manufacturing environments. Overcoming these hurdles is crucial for leveraging predictive analytics and enhancing operational efficiency through digital twin simulations.

Future Trends: Evolving Supply Chain Strategies

Supply Chain Management is increasingly integrating advanced analytics and AI to enhance decision-making efficiency and resilience against disruptions. Supply Chain Digital Twins leverage real-time data and simulations to provide dynamic visibility, enabling proactive adjustments to complex logistics networks. Future trends emphasize the convergence of digital twin technology with IoT and blockchain to create adaptive, transparent, and predictive supply chain strategies.

Related Important Terms

Hyperconnected Supply Networks

Hyperconnected Supply Networks leverage real-time data integration and advanced analytics through Supply Chain Digital Twins to optimize manufacturing operations, enhance visibility, and predict disruptions, surpassing traditional Supply Chain Management's static processes. Digital Twins simulate end-to-end supply chain scenarios, enabling proactive decision-making and agile responses within complex manufacturing ecosystems.

Digital Twin-Driven SCM

Digital Twin-driven Supply Chain Management leverages real-time data and simulation models to optimize inventory levels, predict disruptions, and enhance decision-making accuracy across manufacturing operations. By creating a virtual replica of the supply chain, manufacturers achieve greater visibility, agility, and resilience compared to traditional SCM methods.

Predictive Supply Chain Analytics

Supply Chain Digital Twin leverages real-time data and predictive analytics to simulate and optimize supply chain operations, enabling proactive decision-making and risk mitigation. Predictive Supply Chain Analytics in traditional Supply Chain Management often rely on historical data, limiting the ability to foresee disruptions and adapt swiftly.

Cognitive Supply Chain

Cognitive Supply Chain leverages advanced AI and machine learning within Supply Chain Digital Twin frameworks to deliver real-time analytics and predictive insights, surpassing traditional Supply Chain Management's reactive approach. This integration enables proactive disruption detection, optimized resource allocation, and enhanced decision-making across manufacturing operations.

Supply Chain Control Tower 4.0

Supply Chain Control Tower 4.0 leverages advanced analytics and real-time data integration to optimize visibility, agility, and decision-making within Manufacturing supply chains. Unlike traditional Supply Chain Management, Supply Chain Digital Twin technology creates dynamic simulations of supply networks, enabling proactive risk mitigation and enhanced operational efficiency.

Supply Chain Virtualization

Supply Chain Digital Twin leverages advanced simulation and real-time data analytics to create a virtual replica of the physical supply chain, enabling predictive insights and scenario testing that enhance decision-making and operational efficiency. Unlike traditional Supply Chain Management, Supply Chain Virtualization through digital twins facilitates dynamic response to disruptions, optimizes inventory levels, and streamlines logistics by providing end-to-end visibility and actionable intelligence.

Resilient Digital Twin Modeling

Resilient digital twin modeling in supply chain management enables real-time simulation and proactive risk assessment, enhancing responsiveness to disruptions and improving decision-making accuracy. Unlike traditional supply chain management, digital twins integrate comprehensive data streams and predictive analytics to create adaptive models that optimize inventory, logistics, and supplier interactions dynamically.

AI-augmented Supply Orchestration

AI-augmented Supply Orchestration in supply chain management leverages real-time data and predictive analytics to optimize inventory levels, demand forecasting, and supplier coordination, enhancing responsiveness and reducing operational costs. Compared to traditional Supply Chain Management, Supply Chain Digital Twins create dynamic, virtual models of the entire supply network, enabling scenario simulation and proactive disruption management for increased agility and efficiency.

End-to-End Supply Visibility Twin

Supply Chain Management enables coordination of procurement, production, and logistics to optimize efficiency and reduce costs, while Supply Chain Digital Twin utilizes real-time data and simulation models to create an End-to-End Supply Visibility Twin, enhancing predictive insights and agility. This digital representation integrates live inventories, transportation status, and demand forecasts to provide proactive disruption management and improved decision-making across the entire supply chain.

Autonomous Supply Chain Twin

An Autonomous Supply Chain Twin leverages real-time data integration and AI-driven analytics to simulate, predict, and optimize manufacturing logistics, surpassing traditional Supply Chain Management's static planning methods. This digital twin enables proactive decision-making, reduces operational risks, and enhances supply chain resilience by continuously adapting to dynamic market conditions and disruptions.

Supply Chain Management vs Supply Chain Digital Twin Infographic

industrydif.com

industrydif.com