Underground mining involves the extraction of minerals and ores from deep beneath the earth's surface using tunnels and shafts, which requires significant investment in infrastructure and safety measures. Bio-mining leverages microorganisms to naturally break down and extract metals from ores, offering a more environmentally friendly and cost-effective alternative. Comparing these methods highlights underground mining's high operational risks and expenses against bio-mining's sustainability and potential for processing low-grade ores.

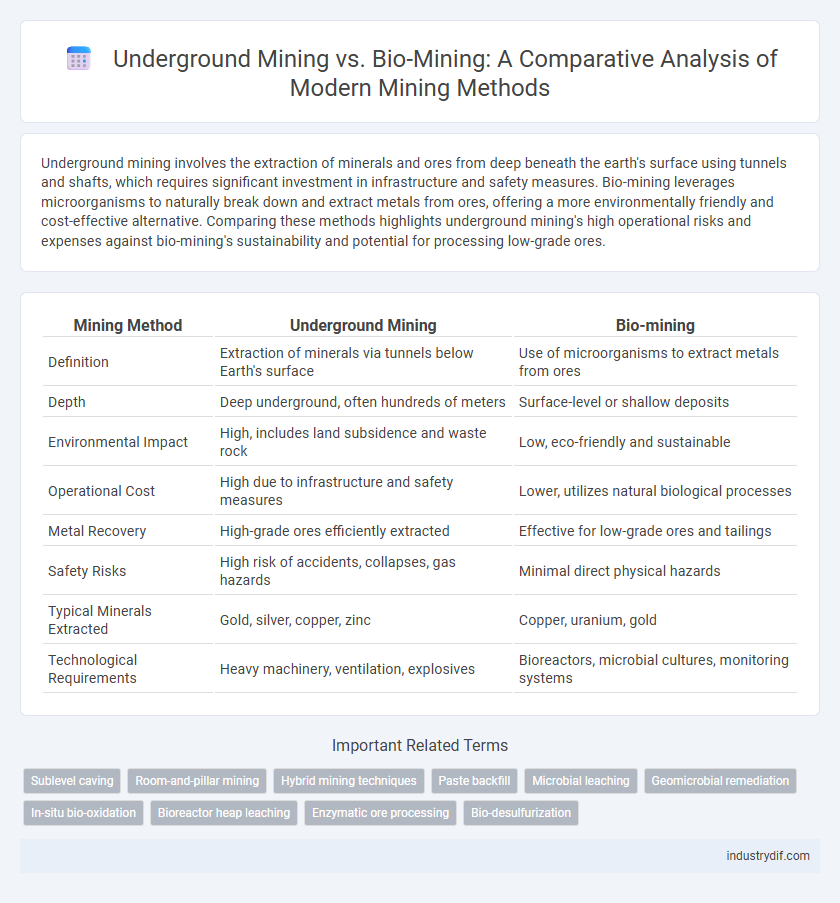

Table of Comparison

| Mining Method | Underground Mining | Bio-mining |

|---|---|---|

| Definition | Extraction of minerals via tunnels below Earth's surface | Use of microorganisms to extract metals from ores |

| Depth | Deep underground, often hundreds of meters | Surface-level or shallow deposits |

| Environmental Impact | High, includes land subsidence and waste rock | Low, eco-friendly and sustainable |

| Operational Cost | High due to infrastructure and safety measures | Lower, utilizes natural biological processes |

| Metal Recovery | High-grade ores efficiently extracted | Effective for low-grade ores and tailings |

| Safety Risks | High risk of accidents, collapses, gas hazards | Minimal direct physical hazards |

| Typical Minerals Extracted | Gold, silver, copper, zinc | Copper, uranium, gold |

| Technological Requirements | Heavy machinery, ventilation, explosives | Bioreactors, microbial cultures, monitoring systems |

Introduction to Underground Mining and Bio-mining

Underground mining involves extracting minerals from beneath the earth's surface through tunnels and shafts, enabling access to deep ore bodies that surface mining cannot reach. Bio-mining uses microorganisms to leach metals like copper, gold, and uranium from ores, offering an eco-friendly alternative that reduces energy consumption and environmental impact compared to traditional methods. Both techniques are critical in sustainable mineral extraction, with underground mining maximizing resource recovery and bio-mining enhancing metal extraction efficiency through biological processes.

Key Principles of Underground Mining

Underground mining involves the excavation of mineral deposits beneath the earth's surface using tunnels, shafts, and chambers, prioritizing safety, ventilation, and structural stability. Key principles include ore body assessment, controlled blasting techniques, and efficient ore extraction methods such as cut and fill or room and pillar mining to minimize environmental impact and enhance worker safety. Bio-mining, in contrast, employs microorganisms to extract metals from ores, offering an eco-friendly alternative but lacking the physical excavation and infrastructure complexities inherent to underground mining.

Core Concepts of Bio-mining

Bio-mining harnesses microorganisms to extract metals from ores through processes such as bioleaching, bio-oxidation, and biomineralization, offering an eco-friendly alternative to traditional underground mining. These microbial techniques enable the recovery of metals like copper, gold, and uranium by breaking down mineral matrices without extensive excavation or blasting. Bio-mining reduces environmental impact, lowers operational costs, and is particularly effective for low-grade and complex ores unsuitable for conventional underground methods.

Comparative Analysis: Extraction Processes

Underground mining involves physical excavation of ore deposits through tunnels or shafts, utilizing drilling, blasting, and hauling techniques to recover minerals. Bio-mining employs microorganisms to biologically leach metals such as copper, gold, and uranium from low-grade ores, reducing environmental impact and operational costs. Extraction efficiency varies as underground mining offers rapid recovery of high-grade ores, whereas bio-mining enables sustainable extraction from ores that are otherwise uneconomical to process.

Environmental Impact Assessment

Underground mining often results in significant land disturbance, habitat destruction, and groundwater contamination, leading to long-term ecological damage requiring comprehensive Environmental Impact Assessments (EIA). Bio-mining utilizes microorganisms to extract metals, minimizing surface disruption and hazardous waste production, thereby presenting a lower environmental footprint in EIA evaluations. Comparative EIA studies highlight bio-mining's potential in sustainable resource extraction by reducing air emissions, water pollution, and soil degradation common in traditional underground mining operations.

Operational Safety and Risk Management

Underground mining poses significant operational safety challenges due to risks such as mine collapses, gas explosions, and limited ventilation, requiring rigorous risk management protocols and advanced monitoring systems. Bio-mining, leveraging microorganisms to extract metals, offers a safer alternative with reduced exposure to hazardous conditions and minimal structural collapse risks, enhancing worker safety. Implementing bio-mining can substantially decrease the likelihood of accidents and occupational illnesses, streamlining risk management in mining operations.

Resource Recovery Efficiency

Underground mining achieves high resource recovery efficiency by accessing deep ore bodies with minimal surface disruption, but it often requires substantial energy and labor inputs. Bio-mining leverages microbial processes to extract metals from low-grade ores and waste materials, enhancing recovery rates while reducing environmental impact and operational costs. Comparing both, bio-mining offers a sustainable alternative with improved selectivity and lower energy consumption, though underground mining remains essential for high-grade resource exploitation.

Cost-Effectiveness and Economic Viability

Underground mining requires significant capital investment in infrastructure, equipment, and labor, often resulting in high operational costs and longer project timelines. Bio-mining utilizes microorganisms to extract metals, offering a cost-effective alternative with lower energy consumption and reduced environmental remediation expenses. Economic viability of bio-mining improves in low-grade ore deposits where traditional underground methods become prohibitively expensive.

Technological Innovations in Mining

Technological innovations in underground mining include automation, remote-controlled equipment, and advanced ventilation systems that enhance safety and efficiency in deep subterranean environments. Bio-mining leverages genetically engineered microorganisms and bioleaching techniques to extract metals like copper and gold with lower environmental impact and reduced energy consumption. Integrating digital sensors and data analytics further optimizes extraction processes in both underground mining and bio-mining methods.

Future Prospects and Industry Trends

Underground mining continues to rely on advanced automation and robotics to improve safety and efficiency, with increasing integration of IoT sensors and AI for real-time monitoring and predictive maintenance. Bio-mining, leveraging microbial processes to extract metals, is gaining momentum due to its environmental benefits and potential to access low-grade ores economically, driven by innovations in biotechnology and genetic engineering. Industry trends indicate a shift toward sustainable practices, with significant investments in bio-leaching techniques and hybrid mining systems that combine traditional methods with bio-mining to enhance resource recovery and reduce ecological impact.

Related Important Terms

Sublevel caving

Sublevel caving is an underground mining method involving the controlled collapse of ore bodies in successive sublevels, optimized for extracting massive, steeply dipping ore deposits with high production rates and cost efficiency. In contrast, bio-mining employs microorganisms to bioleach metals from low-grade ores or waste materials, offering an environmentally sustainable alternative but with slower extraction rates and limited application in high-volume sublevel caving operations.

Room-and-pillar mining

Room-and-pillar mining, a common underground mining method, involves excavating rooms while leaving pillars to support the roof, ensuring miner safety and resource recovery. Bio-mining, an eco-friendly alternative, uses microorganisms to extract metals from ores, reducing environmental impact compared to traditional room-and-pillar operations.

Hybrid mining techniques

Hybrid mining techniques combine underground mining's physical extraction with bio-mining's biologically driven metal recovery, enhancing ore yield and reducing environmental impact. Integrating microbial leaching processes within underground operations optimizes mineral extraction efficiency and promotes sustainable resource management in mining projects.

Paste backfill

Paste backfill in underground mining enhances ground stability by filling voids with a mixture of tailings, binders, and water, enabling safer extraction and reduced surface subsidence. Bio-mining techniques, while primarily focused on microbial leaching of ores, complement paste backfill by potentially reducing tailings volume and environmental impact associated with underground waste disposal.

Microbial leaching

Microbial leaching in bio-mining uses specialized bacteria to extract metals from ores underground, offering an environmentally friendly alternative to traditional underground mining. This method reduces energy consumption and toxins while efficiently recovering copper, gold, and uranium from low-grade ores.

Geomicrobial remediation

Underground mining involves extracting minerals through deep tunnels, often causing significant environmental disturbances, whereas bio-mining leverages geomicrobial remediation by utilizing microorganisms to solubilize and recover metals, reducing ecological impact. Geomicrobial remediation in bio-mining promotes sustainable extraction by accelerating metal recovery from low-grade ores and mining waste while minimizing hazardous waste generation.

In-situ bio-oxidation

In-situ bio-oxidation, a cutting-edge bio-mining technique, enhances metal recovery by utilizing naturally occurring microorganisms to oxidize sulfide ores directly within the underground mine without excavation. This method significantly reduces environmental impact and operational costs compared to traditional underground mining by minimizing waste generation and energy consumption.

Bioreactor heap leaching

Bioreactor heap leaching enhances metal recovery by optimizing microbial activity within controlled, aerated heaps, making it more efficient and environmentally friendly compared to traditional underground mining techniques. This method reduces energy consumption, minimizes surface disturbance, and accelerates bioleaching processes through engineered microbial ecosystems in bioreactors.

Enzymatic ore processing

Enzymatic ore processing in bio-mining leverages natural biological catalysts to extract metals from low-grade ores, reducing environmental impact compared to traditional underground mining methods that rely heavily on mechanical excavation and chemical reagents. Bio-mining's enzymatic techniques enhance metal recovery efficiency while minimizing energy consumption and hazardous waste generation.

Bio-desulfurization

Bio-desulfurization in bio-mining utilizes specialized microorganisms to remove sulfur compounds from ores, offering an eco-friendly alternative to traditional underground mining methods that typically involve extensive drilling and blasting. This biotechnological approach reduces environmental impact and operational costs by enhancing sulfur removal efficiency in sulfide mineral processing.

Underground mining vs Bio-mining Infographic

industrydif.com

industrydif.com