Bulk sampling allows miners to collect and analyze large quantities of ore, providing an accurate representation of mineral content, but it can be time-consuming and costly. Ore sorting enhances processing efficiency by separating valuable minerals from waste material at an early stage, reducing the volume of ore to be processed. Choosing between bulk sampling and ore sorting depends on the project's scale, mineral variability, and cost-effectiveness considerations.

Table of Comparison

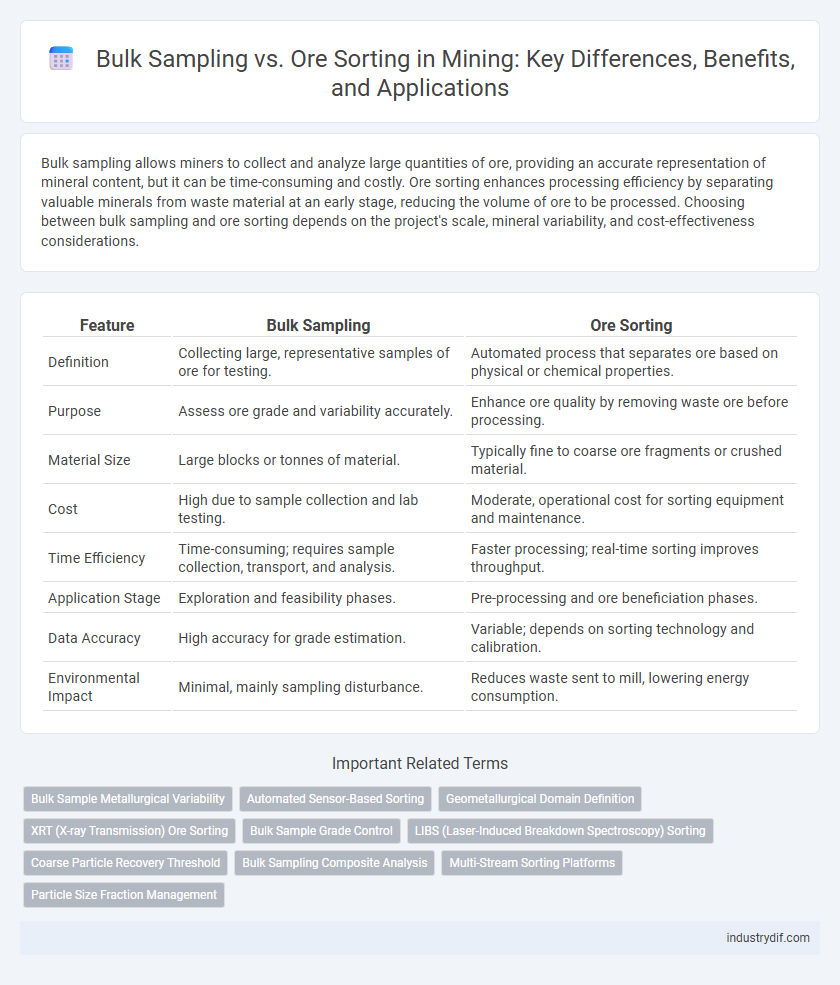

| Feature | Bulk Sampling | Ore Sorting |

|---|---|---|

| Definition | Collecting large, representative samples of ore for testing. | Automated process that separates ore based on physical or chemical properties. |

| Purpose | Assess ore grade and variability accurately. | Enhance ore quality by removing waste ore before processing. |

| Material Size | Large blocks or tonnes of material. | Typically fine to coarse ore fragments or crushed material. |

| Cost | High due to sample collection and lab testing. | Moderate, operational cost for sorting equipment and maintenance. |

| Time Efficiency | Time-consuming; requires sample collection, transport, and analysis. | Faster processing; real-time sorting improves throughput. |

| Application Stage | Exploration and feasibility phases. | Pre-processing and ore beneficiation phases. |

| Data Accuracy | High accuracy for grade estimation. | Variable; depends on sorting technology and calibration. |

| Environmental Impact | Minimal, mainly sampling disturbance. | Reduces waste sent to mill, lowering energy consumption. |

Introduction to Bulk Sampling and Ore Sorting

Bulk sampling involves extracting large, representative samples from a mineral deposit to accurately assess ore grade and distribution, providing critical data for feasibility studies. Ore sorting is a pre-concentration technique that separates valuable minerals from waste rock using sensor-based technologies, optimizing processing efficiency and reducing costs. Both methods play essential roles in resource evaluation and mine planning, with bulk sampling delivering direct grade information while ore sorting enhances selective mining and downstream processing.

Defining Bulk Sampling in Mining Operations

Bulk sampling in mining operations involves extracting large, representative samples of ore to evaluate its quality and mineral content before full-scale mining. This method provides critical data on grade variability and helps in planning efficient extraction strategies. Unlike ore sorting, which separates valuable minerals from waste on a smaller scale, bulk sampling captures a more comprehensive geological profile for accurate resource estimation.

Understanding Ore Sorting Technology

Ore sorting technology uses advanced sensors such as X-ray transmission, near-infrared, or laser-induced fluorescence to analyze and separate valuable ore from waste rock on a granular level. This method improves efficiency by targeting and extracting higher-grade material before processing, reducing energy consumption and operational costs compared to traditional bulk sampling. The precise identification and removal of low-grade or barren material optimize mill feed quality and enhance overall mine productivity.

Key Differences Between Bulk Sampling and Ore Sorting

Bulk sampling involves extracting large quantities of ore to obtain a representative sample for assaying, ensuring accurate determination of grade distribution and mineral content. Ore sorting uses sensor-based technology to separate valuable ore from waste material on a particle-by-particle basis, enhancing ore grade before processing. The key difference lies in bulk sampling's focus on sampling representativeness and ore sorting's emphasis on pre-concentration and waste rejection.

Advantages of Bulk Sampling in Resource Estimation

Bulk sampling provides more accurate and representative data for resource estimation by extracting large, homogenous portions of ore directly from the deposit, reducing sampling bias and variability. This method allows geologists to assess the mineral content and grade distribution more reliably compared to smaller, selective samples. Accurate bulk samples improve the confidence level in resource models, aiding better economic viability assessments and mine planning.

Benefits of Ore Sorting for Grade Control

Ore sorting enhances grade control by enabling precise separation of valuable minerals from waste rock, reducing dilution and improving overall ore quality. This process increases operational efficiency by targeting high-grade material, leading to better resource optimization and lower processing costs. Compared to bulk sampling, ore sorting provides real-time data that facilitates more accurate decision-making in mining operations.

Cost Implications: Bulk Sampling vs Ore Sorting

Bulk sampling involves significant upfront costs due to extensive excavation, transportation, and laboratory testing, often resulting in higher operational expenses. Ore sorting utilizes advanced sensor technology to segregate ore from waste on-site, reducing processing volume and lowering overall handling and processing costs. Cost implications favor ore sorting by enabling selective mining, minimizing waste treatment, and improving resource efficiency.

Environmental Impact Comparison

Bulk sampling in mining generates significant waste due to the large volumes of extracted material requiring transportation and processing, leading to increased energy consumption and greenhouse gas emissions. Ore sorting technology minimizes environmental impact by selectively processing higher-grade material, which reduces waste generation, lowers energy use, and decreases the volume of tailings. This targeted approach also reduces water consumption and lessens the ecological footprint of mining operations compared to traditional bulk sampling.

When to Choose Bulk Sampling Over Ore Sorting

Bulk sampling is preferred over ore sorting when a comprehensive representation of ore variability is critical for accurate resource estimation and metallurgical testwork. It is especially important in deposits with complex geological features or heterogeneous mineralization where ore sorting may fail to capture subtle variations in grade and mineral distribution. Selecting bulk sampling ensures reliable data for process optimization, mine planning, and economic feasibility studies in mineral extraction projects.

Future Trends in Bulk Sampling and Ore Sorting Technologies

Future trends in bulk sampling emphasize automation and real-time data integration to enhance the accuracy and efficiency of ore characterization, reducing resource wastage and operational costs. Ore sorting technologies are advancing through the incorporation of artificial intelligence and hyperspectral imaging, enabling precise mineral differentiation and scalable sorting processes. These innovations collectively drive smarter resource management and improved sustainability in mining operations.

Related Important Terms

Bulk Sample Metallurgical Variability

Bulk sample metallurgical variability impacts the reliability of ore grade estimation, leading to potential inconsistencies in processing efficiency during mining operations. Ore sorting offers more precise mineral discrimination, reducing variability and enhancing recovery rates compared to traditional bulk sampling methods.

Automated Sensor-Based Sorting

Automated sensor-based sorting enhances bulk sampling by rapidly analyzing ore composition and grade with high precision, reducing manual labor and sample variability. This technology improves recovery rates and operational efficiency by selectively isolating valuable minerals before processing, optimizing resource utilization in mining operations.

Geometallurgical Domain Definition

Bulk sampling in geometallurgy involves extracting representative large samples to analyze ore variability and metallurgical properties, providing critical data for process design and resource estimation. Ore sorting employs sensor-based technologies to separate valuable ore from waste, enhancing resource efficiency by optimizing feed quality and reducing processing costs in mineral extraction.

XRT (X-ray Transmission) Ore Sorting

XRT (X-ray Transmission) ore sorting significantly enhances bulk sampling by providing precise material characterization and real-time separation of ore from waste, leading to improved grade control and reduced processing costs. Unlike traditional bulk sampling methods, XRT technology enables non-destructive, automated sorting based on density and atomic number differences, optimizing resource recovery and minimizing environmental impact.

Bulk Sample Grade Control

Bulk sampling provides precise grade control by extracting representative ore volumes for laboratory analysis, ensuring accurate resource estimation and minimizing processing risks. Ore sorting, while efficient for pre-concentration, offers less detailed grade variability data, making bulk samples essential for verifying grade consistency in mining operations.

LIBS (Laser-Induced Breakdown Spectroscopy) Sorting

Bulk sampling provides a comprehensive analysis of ore grade by extracting large volumes, while LIBS sorting offers rapid, real-time elemental analysis enabling precise ore separation on-site. LIBS technology significantly enhances ore sorting efficiency by detecting elemental composition at high speed, reducing processing costs and improving resource recovery.

Coarse Particle Recovery Threshold

Bulk sampling captures a broad representation of ore by processing large, heterogeneous material volumes, enabling a coarse particle recovery threshold typically above 50 mm. Ore sorting targets finer particle sizes with precise separation technologies, achieving more selective recovery often below 30 mm, enhancing operational efficiency and reducing processing costs.

Bulk Sampling Composite Analysis

Bulk sampling composite analysis provides a comprehensive representation of ore grade variability within a mine, ensuring accurate resource estimation and process optimization. Unlike ore sorting, which selectively segregates materials based on physical or chemical properties, bulk sampling captures the heterogeneity of the deposit, enabling more effective metallurgical testing and recovery predictions.

Multi-Stream Sorting Platforms

Multi-stream sorting platforms enhance ore processing efficiency by simultaneously separating valuable minerals from waste through advanced sensor technologies, optimizing bulk sampling accuracy and reducing operational costs. These platforms enable precise targeting of high-grade ore streams, improving resource recovery and minimizing dilution compared to traditional bulk sampling methods.

Particle Size Fraction Management

Bulk sampling involves processing larger particle size fractions to obtain representative mineral content, whereas ore sorting targets finer particle size fractions to enhance grade control and discard waste early in the process. Effective particle size fraction management optimizes recovery rates by aligning sampling or sorting techniques with the specific size characteristics of the mineralized material.

Bulk Sampling vs Ore Sorting Infographic

industrydif.com

industrydif.com