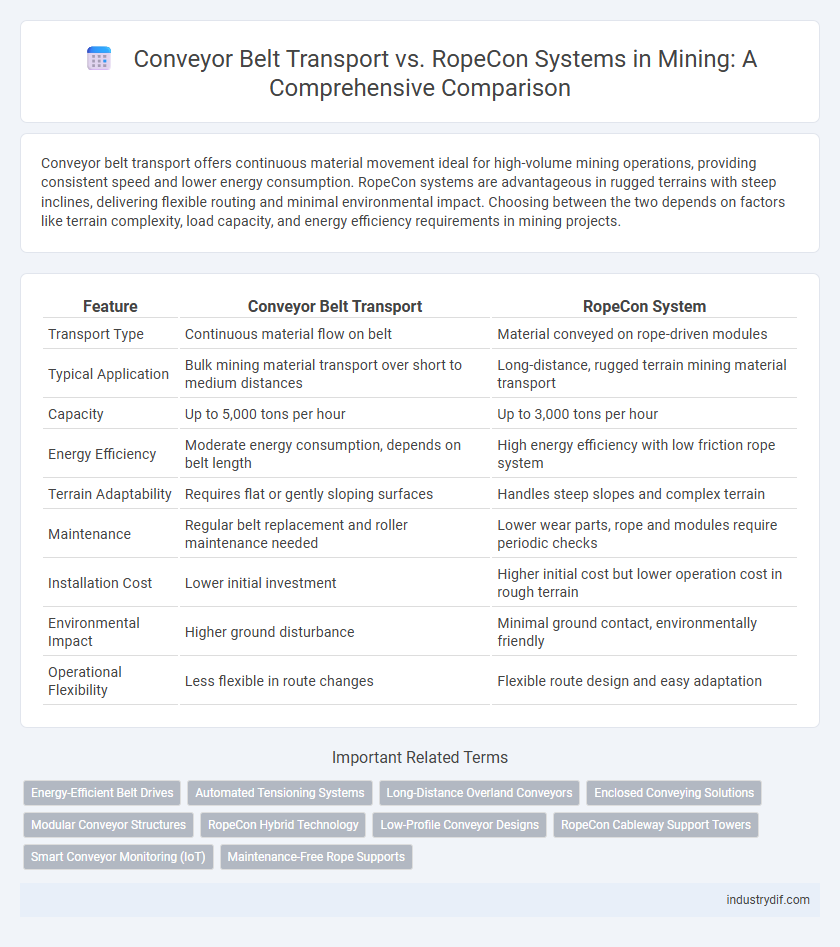

Conveyor belt transport offers continuous material movement ideal for high-volume mining operations, providing consistent speed and lower energy consumption. RopeCon systems are advantageous in rugged terrains with steep inclines, delivering flexible routing and minimal environmental impact. Choosing between the two depends on factors like terrain complexity, load capacity, and energy efficiency requirements in mining projects.

Table of Comparison

| Feature | Conveyor Belt Transport | RopeCon System |

|---|---|---|

| Transport Type | Continuous material flow on belt | Material conveyed on rope-driven modules |

| Typical Application | Bulk mining material transport over short to medium distances | Long-distance, rugged terrain mining material transport |

| Capacity | Up to 5,000 tons per hour | Up to 3,000 tons per hour |

| Energy Efficiency | Moderate energy consumption, depends on belt length | High energy efficiency with low friction rope system |

| Terrain Adaptability | Requires flat or gently sloping surfaces | Handles steep slopes and complex terrain |

| Maintenance | Regular belt replacement and roller maintenance needed | Lower wear parts, rope and modules require periodic checks |

| Installation Cost | Lower initial investment | Higher initial cost but lower operation cost in rough terrain |

| Environmental Impact | Higher ground disturbance | Minimal ground contact, environmentally friendly |

| Operational Flexibility | Less flexible in route changes | Flexible route design and easy adaptation |

Overview of Conveyor Belt Transport and RopeCon Systems

Conveyor belt transport in mining offers continuous, high-capacity material movement, efficiently handling bulk materials over long distances with low energy consumption and minimal maintenance requirements. RopeCon systems combine the advantages of ropeway and conveyor belt technologies, allowing for flexible routing over rough terrain and steep gradients while maintaining high throughput and energy efficiency. Both systems are designed to optimize material flow in mining operations, but RopeCon provides greater adaptability in challenging topographies compared to traditional conveyor belts.

Core Principles and Design Differences

Conveyor belt transport relies on continuous moving belts powered by rollers and motors to efficiently move bulk materials over varied distances, emphasizing durability and energy efficiency in its design. In contrast, ropeCon systems use a looped cable and carrier mechanism that combines cable car technology with conveyor principles, allowing transport over complex terrain and steep gradients where traditional belts struggle. The core difference lies in ropeCon's ability to span long distances with minimal ground impact and elevated pathways, while conveyor belts prioritize straightforward, ground-based material flow.

Material Handling Capacity

Conveyor belt transport systems offer continuous, high-capacity material handling, often exceeding 2,000 tons per hour, making them ideal for large-scale mining operations. Ropecon systems operate with moderate capacity, generally below 1,000 tons per hour, but provide flexibility in challenging terrains and long distances. Selecting between these systems depends on balancing material throughput requirements with site topography and energy efficiency considerations.

Installation and Infrastructure Requirements

Conveyor belt transport systems require extensive infrastructure including robust support frameworks, motorized rollers, and continuous belt materials designed for heavy loads, which involve longer installation times and higher upfront capital investment. In contrast, RopeCon systems feature a modular design with lightweight ropes and carriers that simplify installation, minimize ground disturbance, and require less structural support, making them suitable for complex terrains and environmentally sensitive mining sites. The choice between these systems depends on site-specific factors such as terrain complexity, load capacity, and installation timeframe, with RopeCon offering faster deployment and reduced spatial footprint compared to traditional conveyor belts.

Operational Efficiency and Reliability

Conveyor belt transport in mining offers continuous material flow with high load capacity and minimal energy consumption, enhancing operational efficiency compared to RopeCon systems. RopeCon systems provide flexibility in challenging terrains and steep inclines but often require higher maintenance due to rope wear and system complexity, impacting reliability. Optimizing conveyor belt transport reduces downtime and operational costs, while RopeCon systems are advantageous for site-specific applications demanding adaptable routing and moderate throughput.

Energy Consumption and Cost Analysis

Conveyor belt transport systems typically consume less energy per ton-kilometer compared to ropeCon systems due to their continuous operation and higher efficiency in bulk material handling. The initial capital investment for conveyor belts is generally higher, but their lower maintenance costs and energy consumption lead to reduced operational expenses over time. RopeCon systems, while benefiting from lower upfront costs and better adaptability to rugged terrain, often incur higher energy usage and maintenance costs, impacting long-term cost efficiency in mining operations.

Terrain Adaptability and Flexibility

Conveyor belt transport offers superior terrain adaptability with the ability to efficiently handle varied gradients and curves, making it ideal for complex mining landscapes. RopeCon systems provide enhanced flexibility in installation, especially in rugged or steep terrains where traditional conveyor belts might face limitations. Both systems optimize material flow in mining operations, but Conveyor belts excel in continuous heavy load transport while RopeCon is preferable for difficult topographies requiring minimal infrastructure.

Maintenance Demands and Lifecycle

Conveyor belt transport systems in mining require consistent maintenance to prevent belt wear, motor failures, and misalignment, typically offering a lifecycle of 10-15 years with ongoing component replacements. RopeCon systems demand less frequent maintenance due to their robust rope and carrier design, often extending operational life beyond 20 years while reducing downtime for repairs. The choice between these systems hinges on balancing conveyor belt's higher maintenance intensity against RopeCon's longer lifecycle and lower service interruptions.

Safety Features and Environmental Impact

Conveyor belt transport systems in mining offer enhanced safety through continuous enclosed material movement, reducing airborne dust and minimizing worker exposure to hazardous conditions compared to RopeCon systems, which involve open ropes and buckets prone to spillage. Environmental impact is lower with conveyor belts due to reduced noise emissions and energy efficiency, whereas RopeCon systems can cause soil disturbance and higher energy consumption from mechanical operations. Both systems require rigorous maintenance, but conveyor belts typically provide a safer, more sustainable solution for material handling in mining environments.

Application Suitability in Modern Mining Operations

Conveyor belt transport excels in modern mining operations requiring continuous, high-volume material movement over long distances with minimal energy consumption and maintenance. RopeCon systems demonstrate superior application suitability in complex terrains, steep gradients, and environmentally sensitive areas by combining ropeway flexibility with conveyor efficiency, reducing ground disturbance. Selecting between these systems depends on site-specific factors such as topography, throughput demands, and environmental impact, ensuring optimized operational efficiency and sustainability.

Related Important Terms

Energy-Efficient Belt Drives

Energy-efficient belt drives in conveyor belt transport systems significantly reduce power consumption compared to traditional RopeCon systems by optimizing friction and load distribution. Conveyor belts equipped with advanced drive technologies, such as variable frequency drives and low-resistance pulleys, enhance operational efficiency and lower greenhouse gas emissions in mining operations.

Automated Tensioning Systems

Automated tensioning systems in conveyor belt transport use hydraulic or electric actuators to maintain optimal belt tension, enhancing operational efficiency and reducing maintenance downtime. In contrast, RopeCon systems utilize a continuous loop of ropes with integrated tensioning mechanisms that adjust dynamically, providing consistent load distribution and minimizing belt wear in challenging mining terrains.

Long-Distance Overland Conveyors

Long-distance overland conveyors in mining offer higher efficiency and lower operational costs compared to ropeCon systems, especially for transporting bulk materials across rugged terrains exceeding several kilometers. Conveyor belt transport provides continuous material flow with reduced energy consumption and maintenance requirements, while ropeCon systems are typically limited by terrain complexity and capacity constraints.

Enclosed Conveying Solutions

Enclosed conveying solutions in mining enhance material protection and reduce environmental contamination by preventing dust and spillage, making conveyor belt transport ideal for bulk, continuous movement of abrasive or heavy materials. RopeCon systems offer flexible routing and elevated transport with minimal ground footprint, combining cable-driven efficiency and enclosed belt technology for sensitive or hazardous materials in complex terrain.

Modular Conveyor Structures

Modular conveyor structures in Conveyor Belt Transport offer scalable, customizable configurations that enhance efficiency and maintenance ease compared to RopeCon systems, which are typically fixed in design and less adaptable to changing mine layouts. These modular systems enable rapid installation and reconfiguration, reducing downtime and operational costs while maintaining consistent material flow in mining environments.

RopeCon Hybrid Technology

RopeCon hybrid technology integrates the efficiency of conveyor belt transport with the flexibility of rope systems, enabling continuous bulk material handling over steep gradients and complex terrains in mining operations. This innovative system reduces energy consumption by up to 50% compared to traditional conveyors and can handle capacities exceeding 2,000 tons per hour, making it ideal for large-scale mining projects.

Low-Profile Conveyor Designs

Low-profile conveyor designs in mining enable efficient material transport in constrained spaces, reducing infrastructure costs and minimizing environmental impact compared to traditional ropecon systems. While conveyor belts offer continuous, high-capacity throughput with adjustable speeds, ropecon systems excel in steep inclines and rugged terrain, providing flexibility in challenging underground conditions.

RopeCon Cableway Support Towers

RopeCon cableway support towers are engineered to provide enhanced stability and minimal environmental impact compared to traditional conveyor belt transport systems, enabling efficient material handling over uneven terrain and long distances. These towers are designed to withstand high tensile loads and integrate with modular cable systems, optimizing energy consumption and reducing maintenance costs in mining operations.

Smart Conveyor Monitoring (IoT)

Smart Conveyor Monitoring utilizing IoT technology enhances Conveyor Belt Transport by providing real-time data on belt speed, load, and wear, significantly improving predictive maintenance and reducing downtime in mining operations. Compared to RopeCon systems, IoT-enabled smart conveyors offer scalable, continuous monitoring with advanced analytics that optimize operational efficiency and safety in haulage processes.

Maintenance-Free Rope Supports

Conveyor belt transport systems provide efficient bulk material handling but require frequent maintenance and inspections to ensure belt integrity and roller functionality. RopeCon systems utilize maintenance-free rope supports that drastically reduce downtime and operational costs by eliminating the need for lubrication and component replacement common in traditional conveyor systems.

Conveyor Belt Transport vs RopeCon System Infographic

industrydif.com

industrydif.com