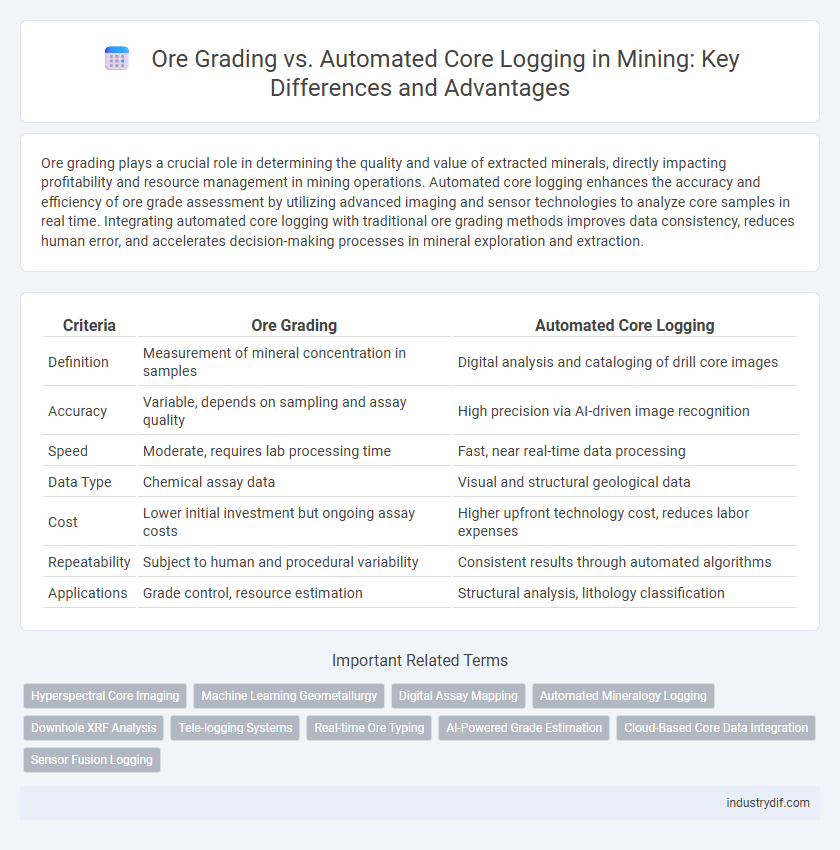

Ore grading plays a crucial role in determining the quality and value of extracted minerals, directly impacting profitability and resource management in mining operations. Automated core logging enhances the accuracy and efficiency of ore grade assessment by utilizing advanced imaging and sensor technologies to analyze core samples in real time. Integrating automated core logging with traditional ore grading methods improves data consistency, reduces human error, and accelerates decision-making processes in mineral exploration and extraction.

Table of Comparison

| Criteria | Ore Grading | Automated Core Logging |

|---|---|---|

| Definition | Measurement of mineral concentration in samples | Digital analysis and cataloging of drill core images |

| Accuracy | Variable, depends on sampling and assay quality | High precision via AI-driven image recognition |

| Speed | Moderate, requires lab processing time | Fast, near real-time data processing |

| Data Type | Chemical assay data | Visual and structural geological data |

| Cost | Lower initial investment but ongoing assay costs | Higher upfront technology cost, reduces labor expenses |

| Repeatability | Subject to human and procedural variability | Consistent results through automated algorithms |

| Applications | Grade control, resource estimation | Structural analysis, lithology classification |

Defining Ore Grading in Modern Mining

Ore grading in modern mining quantifies the concentration of valuable minerals within extracted material, serving as a critical parameter for assessing mine viability and optimizing resource extraction. Automated core logging employs advanced imaging and sensor technologies to precisely measure mineral distribution and geochemical properties, enabling more accurate and rapid ore grade estimation compared to traditional manual methods. Integration of automated core logging systems revolutionizes ore grading accuracy, reduces operational costs, and enhances decision-making in mineral exploration and processing.

Introduction to Automated Core Logging Technologies

Automated core logging technologies utilize advanced imaging systems, machine learning algorithms, and high-resolution sensors to analyze geological core samples with greater precision and speed than traditional ore grading methods. These systems enhance the accuracy of mineral identification, structural feature detection, and data consistency, optimizing resource estimation and reducing human error. Integration of automated core logging into mining workflows improves operational efficiency and supports informed decision-making in mineral exploration and extraction.

Key Differences Between Manual Ore Grading and Automation

Manual ore grading relies on visual inspection and physical sampling, which can be time-consuming and subject to human error, whereas automated core logging uses advanced sensors and imaging technologies to provide precise and consistent data. Automated systems enable real-time data processing and integration with geological software, significantly enhancing accuracy and efficiency in ore characterization. This technological advancement reduces sampling bias and improves decision-making in mine planning and resource estimation.

Accuracy and Consistency: Traditional Methods vs AI-Powered Analysis

Automated core logging employs AI-powered analysis to enhance ore grading accuracy by consistently interpreting mineralogy and geological features, reducing human error associated with traditional visual inspections. Traditional methods often suffer from subjective variability and slower processing times, leading to inconsistencies in ore grade estimations. AI-driven systems provide reproducible data outputs and real-time analysis, significantly improving throughput and reliability in mineral resource evaluation.

Data Collection Workflow: Human Assessment vs Automated Logging

Ore grading traditionally relies on human assessment, where geologists manually interpret core samples, often leading to subjective data and slower processing times. Automated core logging employs advanced imaging and sensor technologies to capture consistent, high-resolution data, enabling faster and more accurate recognition of mineral content and structural features. This shift in data collection workflow enhances precision, reduces human error, and streamlines the overall mining exploration process.

Impact of Automated Core Logging on Resource Estimation

Automated core logging significantly improves ore grading accuracy by providing consistent, high-resolution data that reduces human error and variability in geological interpretation. Enhanced data quality from automated systems enables more precise resource estimation models, increasing confidence in mineral reserve calculations and optimizing mine planning. The integration of automated core logging accelerates data processing, facilitating quicker decision-making and improved resource classification.

Speed and Efficiency: Comparing Processing Times

Ore grading traditionally relies on manual sampling and laboratory assays, which can take days to yield results. Automated core logging systems leverage advanced imaging and machine learning algorithms to rapidly analyze core samples in real-time, reducing processing times from days to hours. This acceleration enhances decision-making efficiency, enabling faster resource evaluation and mine planning.

Integration of Automated Systems in Ore Grade Control

Integration of automated core logging systems enhances ore grade control by providing real-time, high-resolution mineralogical data that improves the accuracy and consistency of ore grade estimation. Automated core logging utilizes advanced imaging and sensor technologies to rapidly assess core characteristics, reducing human error and enabling seamless data integration with geological models. This synergy between automated data acquisition and ore grade analysis optimizes resource classification, mine planning, and operational efficiency.

Cost-Benefit Analysis: Manual Grading Versus Automation

Manual ore grading remains labor-intensive and prone to human error, driving higher operational costs and slower turnaround times. Automated core logging employs advanced imaging and AI algorithms to enhance accuracy, reduce grading time by up to 50%, and lower long-term expenses despite initial investment. Cost-benefit analysis reveals automation improves consistency and data integration, ultimately increasing resource estimation reliability and optimizing mine planning efficiency.

Future Trends: Advancements in Core Logging and Ore Grading Technologies

Future trends in mining highlight advancements in automated core logging combined with sophisticated ore grading technologies, enhancing accuracy and efficiency in mineral evaluation. Machine learning algorithms integrated with high-resolution imaging enable real-time data analysis, reducing human error and accelerating decision-making processes. Emerging techniques such as hyperspectral imaging and AI-driven pattern recognition promise to revolutionize ore grade assessment, optimizing resource extraction and reducing operational costs.

Related Important Terms

Hyperspectral Core Imaging

Hyperspectral core imaging enhances ore grading accuracy by providing detailed mineralogical data through non-destructive hyperspectral analysis, enabling automated core logging to identify and quantify ore minerals with high precision. This technology increases the efficiency and consistency of core data interpretation, reducing subjective bias and accelerating the exploration-to-production workflow in mining operations.

Machine Learning Geometallurgy

Machine learning in geometallurgy enhances ore grading accuracy by automating core logging, enabling rapid analysis of mineralogical data and real-time prediction of ore quality. This integration optimizes resource estimation and reduces variability in grade control, driving efficiency in mining operations.

Digital Assay Mapping

Digital Assay Mapping enhances ore grading accuracy by integrating high-resolution geochemical data with automated core logging, enabling precise mineral identification and quantification. This fusion of technologies improves resource estimation and reduces sampling errors, optimizing the mining exploration process.

Automated Mineralogy Logging

Automated mineralogy logging enhances ore grading accuracy by providing detailed, high-resolution mineralogical data that traditional methods cannot match, enabling precise characterization of ore composition and grade variability. By integrating advanced imaging and AI-driven analysis, automated core logging streamlines mineral identification, reduces human error, and accelerates decision-making in mining operations.

Downhole XRF Analysis

Downhole XRF analysis enhances ore grading accuracy by providing real-time, in situ elemental composition data during automated core logging, reducing sampling errors and improving resource estimation. This technology accelerates geological decision-making by integrating precise geochemical insights with automated core imaging for optimized mining exploration.

Tele-logging Systems

Ore grading accuracy is significantly enhanced by tele-logging systems, which automate core logging through real-time data capture and AI-driven mineral identification. These systems reduce human error, increase throughput, and enable precise ore body modeling essential for optimized mine planning and resource estimation.

Real-time Ore Typing

Real-time ore typing enhances ore grading accuracy by integrating automated core logging technologies that analyze mineralogical and geochemical properties instantly during drilling. This fusion of data enables precise grade control and optimizes mine planning through immediate feedback on ore quality variations.

AI-Powered Grade Estimation

AI-powered grade estimation in mining leverages automated core logging to enhance ore grading accuracy by analyzing mineral compositions and geological features in real-time. This integration improves resource modeling, reduces human error, and optimizes extraction strategies based on precise, data-driven grade predictions.

Cloud-Based Core Data Integration

Cloud-based core data integration enhances ore grading accuracy by centralizing and automating core logging data, enabling real-time analytics and consistent classification across multiple drilling sites. This digital transformation reduces human error, accelerates decision-making, and improves resource estimation reliability for mining operations.

Sensor Fusion Logging

Sensor fusion logging enhances ore grading accuracy by integrating data from multiple automated core logging technologies, such as hyperspectral imaging, X-ray fluorescence, and laser scanning. This fusion improves mineral identification and compositional analysis, supporting more precise resource estimation and optimized mining operations.

Ore grading vs Automated core logging Infographic

industrydif.com

industrydif.com