Open-pit mining involves extracting minerals from an open excavation in the earth's surface, offering high production rates and ease of access for large-scale operations. Bioleaching utilizes microorganisms to chemically break down metal sulfides, providing an environmentally friendly alternative for recovering metals from low-grade ores. The choice between open-pit mining and bioleaching depends on ore type, environmental considerations, and economic factors.

Table of Comparison

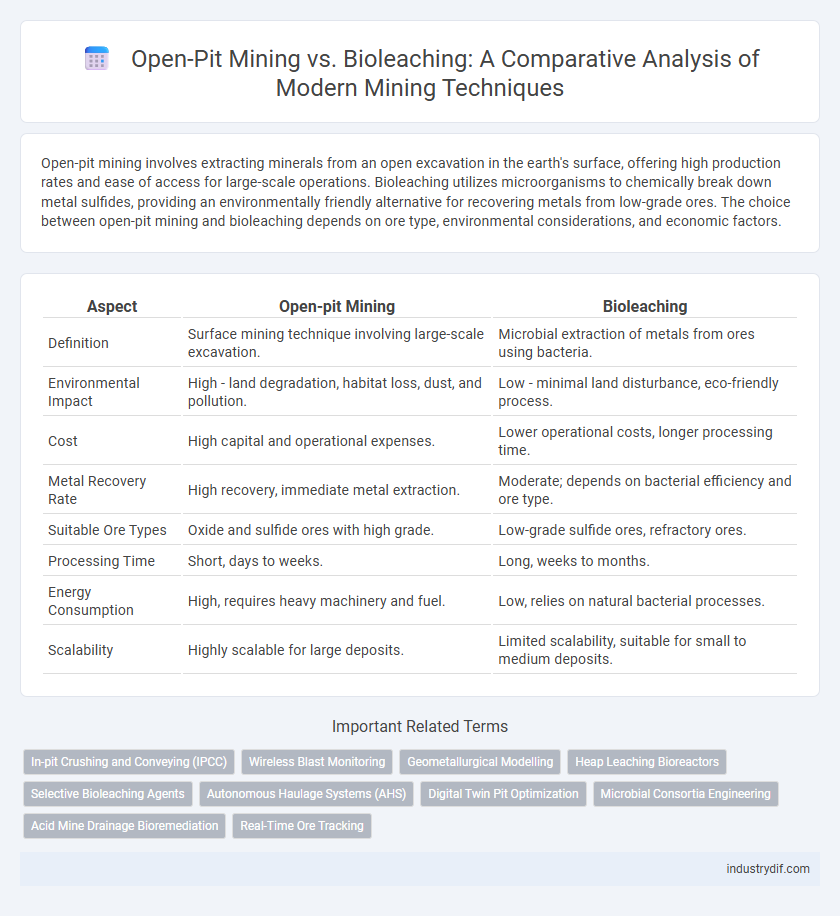

| Aspect | Open-pit Mining | Bioleaching |

|---|---|---|

| Definition | Surface mining technique involving large-scale excavation. | Microbial extraction of metals from ores using bacteria. |

| Environmental Impact | High - land degradation, habitat loss, dust, and pollution. | Low - minimal land disturbance, eco-friendly process. |

| Cost | High capital and operational expenses. | Lower operational costs, longer processing time. |

| Metal Recovery Rate | High recovery, immediate metal extraction. | Moderate; depends on bacterial efficiency and ore type. |

| Suitable Ore Types | Oxide and sulfide ores with high grade. | Low-grade sulfide ores, refractory ores. |

| Processing Time | Short, days to weeks. | Long, weeks to months. |

| Energy Consumption | High, requires heavy machinery and fuel. | Low, relies on natural bacterial processes. |

| Scalability | Highly scalable for large deposits. | Limited scalability, suitable for small to medium deposits. |

Overview of Open-pit Mining and Bioleaching

Open-pit mining involves excavating large surface pits to extract minerals close to the earth's surface, enabling efficient removal of ores such as copper, gold, and iron. Bioleaching utilizes specific microorganisms to biologically extract metals from low-grade ores through the oxidation of sulfide minerals, offering an environmentally friendly alternative. Both methods differ significantly in operational scale, environmental impact, and suitability based on ore type and deposit depth.

Key Processes in Open-pit Mining

Open-pit mining involves the removal of large quantities of surface rock and soil to access mineral deposits, focusing on drilling, blasting, and hauling processes to extract ores efficiently. Key processes include excavation using heavy machinery, transportation of materials to processing sites, and ore crushing for further refining. This method contrasts with bioleaching, which utilizes microorganisms to extract metals from ores without extensive surface disturbance.

Bioleaching: Biological Extraction Explained

Bioleaching utilizes microorganisms such as Acidithiobacillus ferrooxidans to biologically extract metals like copper, gold, and nickel from low-grade ores by oxidizing sulfide minerals. Unlike open-pit mining, bioleaching significantly reduces environmental impact by minimizing land disruption, toxic tailings, and energy consumption. This sustainable technique enhances metal recovery in complex ores, supporting eco-friendly mining practices and reducing operational costs.

Comparative Environmental Impacts

Open-pit mining generates significant environmental disturbances including habitat destruction, soil erosion, and large-scale landscape alteration, often leading to water contamination through acid mine drainage. Bioleaching offers a more sustainable alternative by utilizing microorganisms to extract metals, significantly reducing toxic waste and minimizing water and soil pollution. Compared to open-pit mining, bioleaching has a lower carbon footprint and promotes ecosystem preservation by avoiding extensive land excavation and preserving biodiversity.

Economic Considerations and Cost Analysis

Open-pit mining requires significant upfront capital investment for excavation, equipment, and labor, with ongoing operational costs influenced by ore grade and site scale, often making it cost-effective for high-grade deposits. Bioleaching involves lower capital expenditure and energy use, leveraging microorganisms to extract metals from low-grade ores, which reduces environmental remediation costs but generally entails slower metal recovery rates impacting project timelines. Economic feasibility depends on mineral concentration, market prices, and processing duration, where bioleaching offers cost advantages in remote or low-grade scenarios, while open-pit mining remains preferable for rapid returns on richer deposits.

Ore Types Suitable for Each Method

Open-pit mining is ideal for extracting large, shallow, and low-grade ore deposits such as copper, gold, and iron ores found near the surface, allowing economical removal of overburden and easy access to ore. Bioleaching is particularly suitable for low-grade sulfide ores like chalcopyrite and arsenopyrite, where microorganisms extract metals through biochemical oxidation, minimizing environmental impact and processing costs. Ore types rich in sulfides benefit from bioleaching, while oxidized or oxide ores are more efficiently processed by traditional open-pit mining methods.

Technological Advancements in Extraction

Open-pit mining, characterized by large-scale excavation and heavy machinery, has seen significant technological advancements such as autonomous vehicles and precision blasting, enhancing extraction efficiency and safety. Bioleaching employs microorganisms to extract metals from ores, with innovations in microbial genetics and bioreactor design improving metal recovery rates and environmental sustainability. Both methods show progressive integration of digital monitoring and process optimization technologies, driving the future of mineral extraction.

Recovery Rates and Metal Yields

Open-pit mining typically achieves higher initial metal recovery rates, often exceeding 85%, due to direct extraction of ore with high-grade deposits. Bioleaching, while slower, can enhance total metal yields by efficiently processing low-grade ores and tailings through microbial activity, often improving recovery rates up to 70-90% over prolonged periods. The choice between methods depends on ore type, environmental impact, and long-term yield optimization, with bioleaching offering sustainable advantages in metal recovery from complex ores.

Safety and Regulations in Extraction Methods

Open-pit mining poses significant safety risks including landslides, dust exposure, and heavy equipment accidents, necessitating strict regulatory compliance with occupational health and environmental standards to minimize hazards. Bioleaching offers a safer alternative by utilizing microorganisms to extract metals, reducing the risks associated with physical excavation and chemical toxicity, thereby easing adherence to environmental regulations. Regulatory frameworks increasingly favor bioleaching due to its lower environmental impact and enhanced worker safety compared to traditional open-pit mining methods.

Future Trends in Mining Technology

Open-pit mining, a traditional excavation method, dominates large-scale mineral extraction but faces challenges due to environmental impact and higher operational costs. Bioleaching, an emerging biotechnology, leverages microorganisms to extract metals such as copper and gold from low-grade ores, offering a sustainable and energy-efficient alternative. Future trends in mining technology prioritize integrating bioleaching with automation and data analytics to enhance resource recovery, reduce carbon footprints, and optimize supply chain efficiency.

Related Important Terms

In-pit Crushing and Conveying (IPCC)

In-pit Crushing and Conveying (IPCC) significantly enhances open-pit mining efficiency by reducing haul truck dependency and lowering fuel consumption, while bioleaching offers an environmentally friendly alternative for metal extraction but lacks the immediate operational scalability of IPCC systems. Integrating IPCC with open-pit mining optimizes ore transport logistics, whereas bioleaching focuses on sustainable processing for low-grade ores with minimized environmental impact.

Wireless Blast Monitoring

Wireless blast monitoring enhances safety and efficiency in open-pit mining by providing real-time data on vibrations and air blasts, enabling precise control of explosive impacts. In bioleaching operations, wireless sensors track environmental parameters to optimize microbial activity, reducing the need for physical monitoring and lowering operational risks.

Geometallurgical Modelling

Open-pit mining requires extensive geometallurgical modelling to effectively map ore body characteristics, optimize extraction processes, and manage environmental impacts while bioleaching integrates geometallurgical data to enhance microbial metal recovery by targeting specific mineralogical properties. Advanced modeling techniques support decision-making by predicting ore variability, process performance, and recovery rates, making bioleaching a sustainable alternative in low-grade ore scenarios compared to conventional open-pit methods.

Heap Leaching Bioreactors

Heap leaching bioreactors enhance the bioleaching process by optimizing microbial activity, temperature, and aeration to increase metal recovery rates from low-grade ores compared to traditional open-pit mining. This method reduces environmental impact by minimizing waste generation and energy consumption, offering a sustainable alternative for extracting valuable metals such as copper and gold.

Selective Bioleaching Agents

Selective bioleaching agents such as Acidithiobacillus ferrooxidans offer targeted extraction of metals from low-grade ores, reducing environmental impact compared to traditional open-pit mining, which involves extensive land disruption and waste generation. Bioleaching's specificity enhances metal recovery efficiency by solubilizing valuable metals like copper and gold while minimizing the extraction of unwanted materials.

Autonomous Haulage Systems (AHS)

Autonomous Haulage Systems (AHS) significantly enhance operational efficiency and safety in open-pit mining by automating heavy-duty transport trucks, reducing labor costs and minimizing human error. While bioleaching offers an eco-friendly alternative for metal extraction through microbial processing, AHS remains critical for the large-scale material movement and site logistics typical of open-pit operations.

Digital Twin Pit Optimization

Digital Twin Pit Optimization enhances open-pit mining by creating detailed virtual models for real-time monitoring and predictive analysis, enabling precise extraction strategies and minimizing operational costs. Integrating bioleaching data into digital twins optimizes metal recovery processes, reduces environmental impact, and improves resource efficiency through dynamic simulation of chemical reactions and heap leach performance.

Microbial Consortia Engineering

Open-pit mining involves large-scale excavation that can cause significant environmental disruption, while bioleaching utilizes microbial consortia engineering to optimize the extraction of metals from ores through biologically driven processes. Tailoring microbial communities enhances metal recovery efficiency and reduces ecological impact compared to traditional open-pit mining techniques.

Acid Mine Drainage Bioremediation

Open-pit mining generates significant volumes of acid mine drainage (AMD) due to the exposure of sulfide minerals, requiring extensive bioremediation strategies to mitigate environmental harm. Bioleaching utilizes specialized microorganisms to accelerate metal extraction while simultaneously facilitating AMD bioremediation through the degradation of sulfates and neutralization of acidity.

Real-Time Ore Tracking

Open-pit mining relies on traditional excavation methods where ore tracking is often limited to periodic sampling and manual data collection, resulting in delayed decision-making. Bioleaching integrates real-time ore tracking through microbial activity monitoring and sensor technologies, enabling continuous assessment of ore quality and enhancing recovery efficiency.

Open-pit mining vs Bioleaching Infographic

industrydif.com

industrydif.com