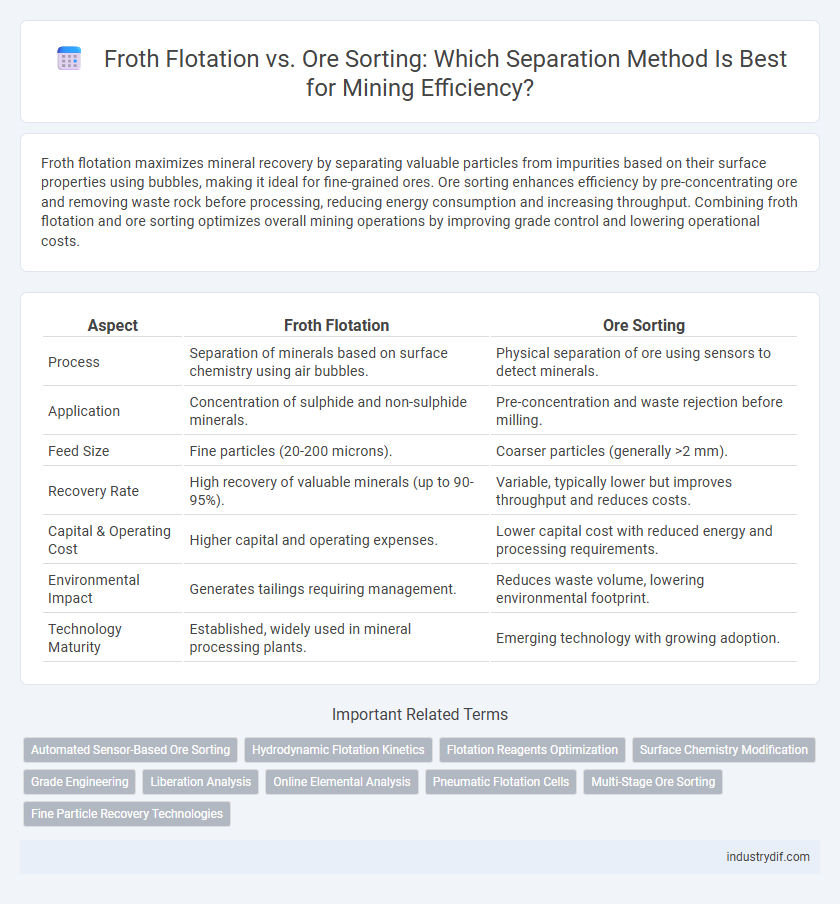

Froth flotation maximizes mineral recovery by separating valuable particles from impurities based on their surface properties using bubbles, making it ideal for fine-grained ores. Ore sorting enhances efficiency by pre-concentrating ore and removing waste rock before processing, reducing energy consumption and increasing throughput. Combining froth flotation and ore sorting optimizes overall mining operations by improving grade control and lowering operational costs.

Table of Comparison

| Aspect | Froth Flotation | Ore Sorting |

|---|---|---|

| Process | Separation of minerals based on surface chemistry using air bubbles. | Physical separation of ore using sensors to detect minerals. |

| Application | Concentration of sulphide and non-sulphide minerals. | Pre-concentration and waste rejection before milling. |

| Feed Size | Fine particles (20-200 microns). | Coarser particles (generally >2 mm). |

| Recovery Rate | High recovery of valuable minerals (up to 90-95%). | Variable, typically lower but improves throughput and reduces costs. |

| Capital & Operating Cost | Higher capital and operating expenses. | Lower capital cost with reduced energy and processing requirements. |

| Environmental Impact | Generates tailings requiring management. | Reduces waste volume, lowering environmental footprint. |

| Technology Maturity | Established, widely used in mineral processing plants. | Emerging technology with growing adoption. |

Introduction to Froth Flotation and Ore Sorting

Froth flotation is a mineral processing technique that separates hydrophobic materials from hydrophilic substances by creating a froth layer where targeted particles attach to air bubbles. Ore sorting uses sensor-based technology, such as X-ray or optical sensors, to identify and physically separate valuable minerals from waste rock before grinding. Both methods improve ore grade and reduce processing costs in mining operations by increasing the efficiency of mineral recovery.

Principles and Mechanisms of Froth Flotation

Froth flotation operates on the principle of separating hydrophobic materials from hydrophilic ones using air bubbles to selectively attach and lift valuable minerals from ore. The mechanism involves crushing the ore into fine particles, mixing with water and reagents that create a froth layer, enabling the hydrophobic particles to adhere to air bubbles and rise to the surface for collection. This process enhances the concentration of target minerals, making froth flotation highly effective for sulfide ores and complex mineral mixtures compared to physical separation methods like ore sorting.

Core Technologies in Ore Sorting

Core technologies in ore sorting include X-ray transmission (XRT), near-infrared (NIR) spectroscopy, and laser-induced breakdown spectroscopy (LIBS), which enable precise identification and separation of valuable minerals from waste. These sensor-based systems provide real-time analysis that enhances ore grade and reduces processing costs compared to traditional froth flotation. Advanced optical and atomic emission techniques in ore sorting optimize resource extraction by improving selectivity and recovery rates in complex ore deposits.

Comparative Efficiency: Froth Flotation vs Ore Sorting

Froth flotation achieves higher recovery rates for fine and complex sulfide ores by selectively separating valuable minerals from gangue using surfactants and air bubbles, which enhances mineral purity and grade. Ore sorting excels in pre-concentration by removing waste rock based on physical and chemical properties, reducing downstream processing and energy consumption but showing lower efficiency for finely disseminated minerals. Froth flotation's adaptability to diverse ore types and finer particle sizes generally results in superior overall mineral recovery compared to ore sorting's targeted, coarse particle separation.

Feed Material Requirements and Preprocessing

Froth flotation requires finely ground feed material, often below 200 mesh, to maximize surface area for effective attachment of hydrophobic particles to air bubbles, necessitating extensive comminution and reagent conditioning. Ore sorting, in contrast, works best with coarser feed material, typically in the range of 10-100 mm, enabling direct separation based on physical properties like color, density, or conductivity with minimal preprocessing. The differing feed size requirements significantly influence energy consumption and processing flow design in mineral beneficiation operations.

Cost Analysis: Capital and Operational Expenditure

Froth flotation requires significant capital investment for flotation cells, reagents, and infrastructure, with operational expenditures driven by energy consumption, chemical usage, and maintenance. Ore sorting presents lower upfront capital costs due to simpler equipment and reduced processing stages, alongside decreased operational costs by minimizing the volume of material processed downstream. Cost analysis reveals froth flotation delivers higher recovery rates but at increased expense, whereas ore sorting offers cost-effective pre-concentration by reducing feed tonnage and energy usage in bulk ore processing.

Environmental Impact and Sustainability

Froth flotation and ore sorting differ significantly in environmental impact and sustainability, with ore sorting offering a more eco-friendly alternative by reducing waste generation and energy consumption during mineral processing. Froth flotation requires substantial water usage and chemical reagents, leading to potential water pollution and challenges in tailings management. Ore sorting enhances resource efficiency by pre-concentration of ore, minimizing the volume of material processed downstream and lowering greenhouse gas emissions associated with crushing and grinding.

Mineral Recovery Rates and Product Purity

Froth flotation typically achieves mineral recovery rates between 85% and 95%, excelling in recovering fine-grained minerals, while ore sorting offers selective extraction with recovery rates around 70% to 90%, depending on ore heterogeneity. Product purity from froth flotation often reaches 90%-98% concentrate grade by effectively separating sulfide minerals, whereas ore sorting enhances feed quality by removing waste before milling, improving overall product purity but generally achieving lower concentrate grades alone. The choice between froth flotation and ore sorting hinges on ore mineralogy, desired recovery efficiency, and product quality targets within mineral processing operations.

Application Scenarios and Ore Types

Froth flotation is highly effective for fine-grained sulfide ores and complex polymetallic deposits, enabling selective mineral separation through chemical reagents and air bubbles. Ore sorting excels with coarse, high-grade ores such as massive sulfides or oxidized minerals, leveraging sensor-based technologies like X-ray, optical, or magnetic detection to reject waste before comminution. Application choice depends on ore characteristics, with froth flotation suited for lower-grade, finely disseminated ores and ore sorting optimal for high-grade, coarse fragments to enhance downstream efficiency.

Future Trends in Mineral Processing Technologies

Froth flotation remains a cornerstone in mineral beneficiation, effectively recovering fine particles with high selectivity, yet emerging ore sorting technologies offer promising advancements by enhancing pre-concentration efficiency and reducing downstream processing costs. Future trends emphasize hybrid systems combining sensor-based sorting with flotation to optimize resource utilization and minimize environmental impact. Innovations in machine learning and real-time data analytics are driving smarter, adaptive mineral processing workflows to improve ore grade control and recovery rates.

Related Important Terms

Automated Sensor-Based Ore Sorting

Automated sensor-based ore sorting enhances mineral recovery by rapidly separating valuable ore from waste using advanced technologies such as X-ray transmission, laser-induced breakdown spectroscopy, and near-infrared sensors. Compared to froth flotation, ore sorting reduces processing volume and energy consumption by pre-concentrating ore, lowering operational costs and increasing plant efficiency.

Hydrodynamic Flotation Kinetics

Hydrodynamic flotation kinetics in froth flotation optimizes particle-bubble collision and attachment rates, enhancing recovery of fine and complex ores compared to ore sorting's mechanical separation methods. This process improves selectivity and recovery efficiency by exploiting mineral surface properties and slurry dynamics, outperforming ore sorting in treating low-grade or finely disseminated mineral deposits.

Flotation Reagents Optimization

Flotation reagents optimization enhances mineral recovery efficiency by adjusting collector, frother, and modifier concentrations to improve selectivity and flotation kinetics in froth flotation processes. Ore sorting relies more on physical property differentiation, making reagent optimization less critical, whereas tailored reagent schemes in flotation directly impact grade and recovery outcomes.

Surface Chemistry Modification

Froth flotation leverages selective surface chemistry modification by attaching collectors and frothers to mineral particles, enhancing hydrophobicity for efficient separation, whereas ore sorting relies on physical and chemical surface property differences without extensive chemical modification. Surface treatment in froth flotation targets specific mineral surfaces to optimize attachment to bubbles, improving recovery rates compared to the minimal surface chemistry adjustments in ore sorting technology.

Grade Engineering

Froth flotation enhances mineral concentration by leveraging surface chemistry to separate valuable ores from gangue, achieving high-grade recovery in fine particles. Ore sorting utilizes sensor-based technologies such as X-ray or near-infrared to pre-concentrate ore streams, improving grade engineering by rejecting low-grade material at an early stage and reducing downstream processing costs.

Liberation Analysis

Froth flotation excels in processing fine particles by exploiting surface chemistry differences, making it effective for complex ores with finely disseminated minerals, as shown by detailed liberation analysis. Ore sorting enhances feed quality by physically separating particles based on size, density, or optical properties, improving downstream flotation efficiency when liberation analysis indicates sufficient particle liberation.

Online Elemental Analysis

Froth flotation relies on chemical reagents to separate minerals based on surface properties, while ore sorting utilizes real-time online elemental analysis such as X-ray fluorescence (XRF) or laser-induced breakdown spectroscopy (LIBS) to rapidly assess mineral composition for selective sorting. Online elemental analysis enhances ore sorting efficiency by providing precise, immediate data that enables higher recovery rates and improved grade control compared to the bulk separation approach of froth flotation.

Pneumatic Flotation Cells

Pneumatic flotation cells, central to froth flotation, enhance the separation efficiency of valuable minerals by generating fine air bubbles that selectively attach to hydrophobic particles, unlike ore sorting which relies on physical or chemical sensor-based separation. These cells improve recovery rates and reduce processing costs in complex ores by enabling better control of flotation dynamics compared to conventional mechanical cells.

Multi-Stage Ore Sorting

Multi-stage ore sorting enhances mineral recovery and grade by sequentially removing gangue minerals before flotation, reducing processing volume and energy consumption. Compared to froth flotation alone, multi-stage sorting improves overall efficiency, lowers operational costs, and increases concentrate quality by targeting ore heterogeneity at multiple points.

Fine Particle Recovery Technologies

Froth flotation excels at recovering fine particles by creating air bubbles that selectively attach to mineral particles, enabling efficient separation of valuable ores from gangue. Ore sorting, using advanced sensor-based technologies such as X-ray transmission and near-infrared spectroscopy, enhances fine particle recovery by accurately distinguishing and segregating ore particles at high throughput rates.

Froth Flotation vs Ore Sorting Infographic

industrydif.com

industrydif.com